Feeler lever for printing and dyeing machine maintenance illumination

A probe rod and mechanical technology, which is applied in the field of probe rods for printing and dyeing machinery maintenance and lighting, can solve the problems of cumbersome and inconvenient unfolding operation process, and achieve the effect of simplifying the process of telescopic use and convenient and quick deployment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

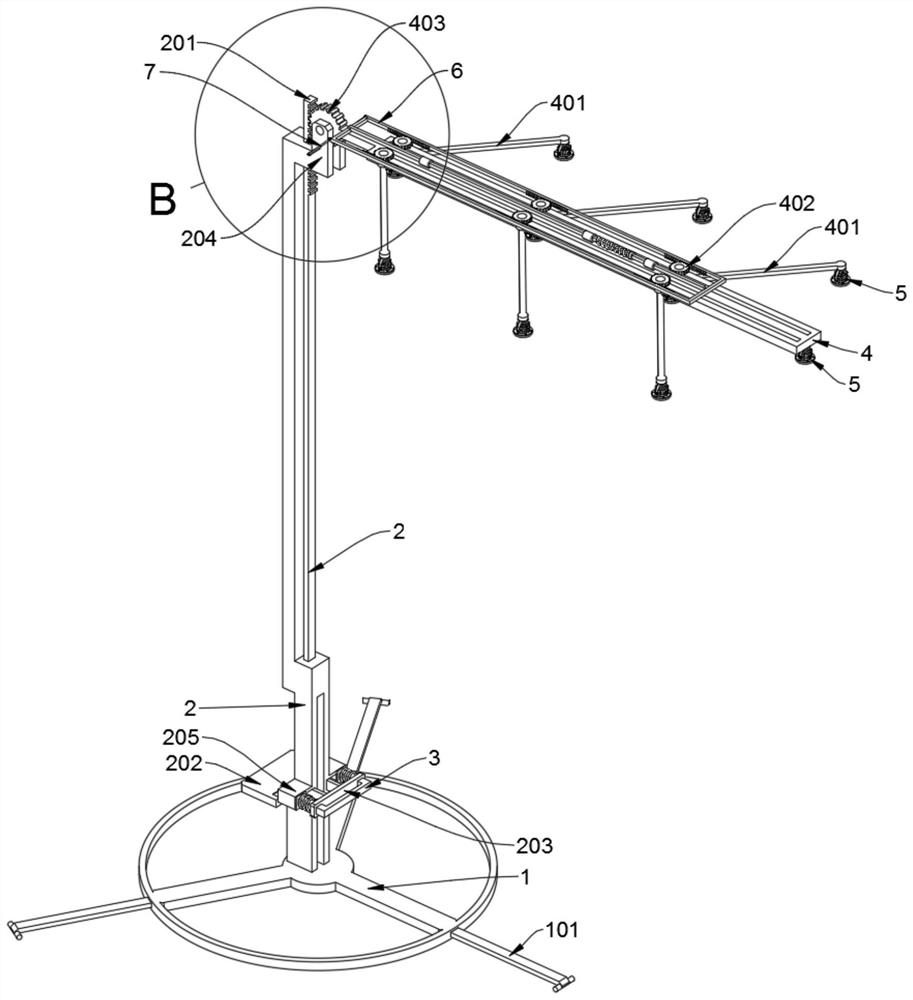

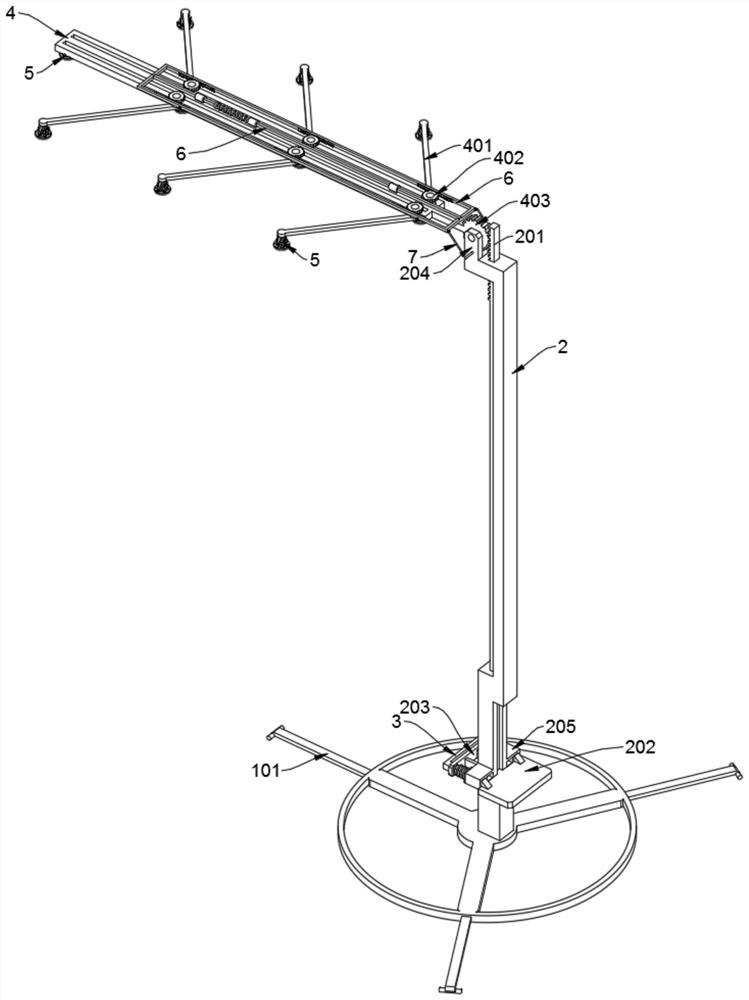

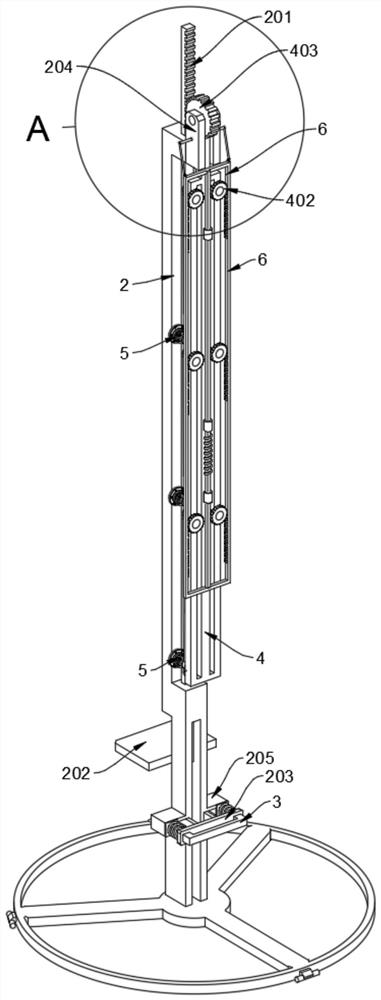

[0031] see Figure 1 to Figure 11 , an embodiment provided by the present invention: a probe rod for maintenance and lighting of printing and dyeing machinery, including a circular base 1, the circular base 1 includes a stabilizing strut 101, and a trident is welded inside the circular base 1 Bracket, a main body support 2 is welded vertically at the center of the trident bracket, and a stabilizing strut 101 is slidably installed in each pole of the trident bracket; the main body support 2 includes a pull rod 201, a positioning plate 203 , the vertical support ear plate 204 and the positioning square sleeve 205, the main body support part 2 is composed of two left an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com