Upper-layer anti-electric shock method for same-pole erected line

A technology for erecting on the same pole and preventing electric shock, which is applied to the spatial arrangement/configuration of overhead lines/cable equipment, cables, etc., can solve the problems of potential safety hazards, insufficient dynamic safety distance, etc., to achieve safety assurance, meet dynamic operating conditions, Compact and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

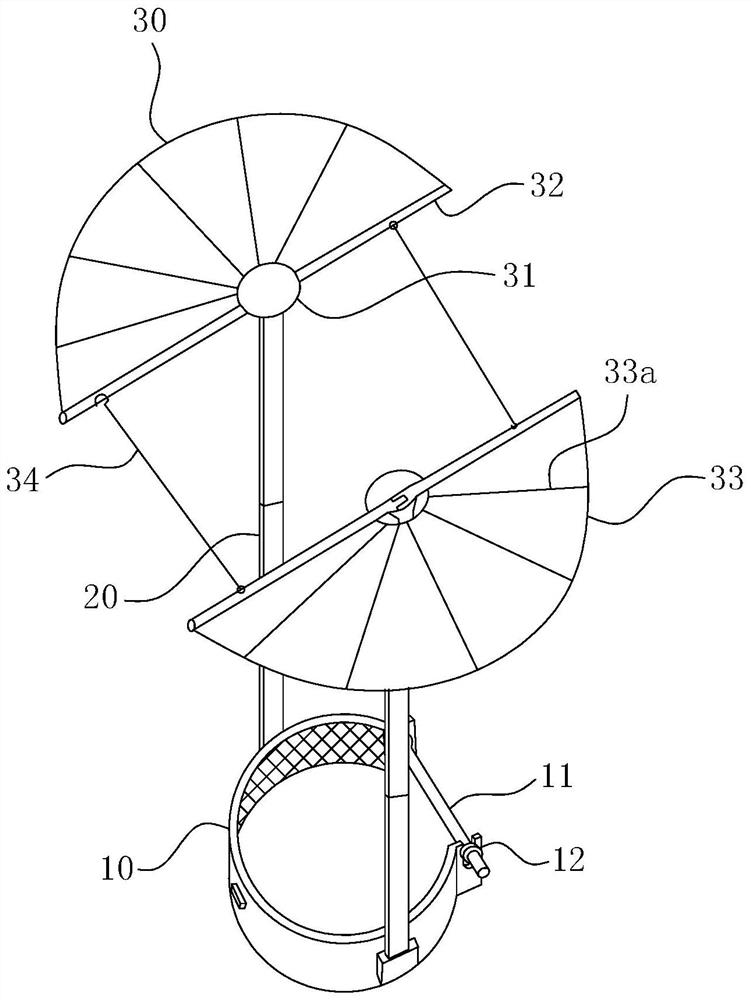

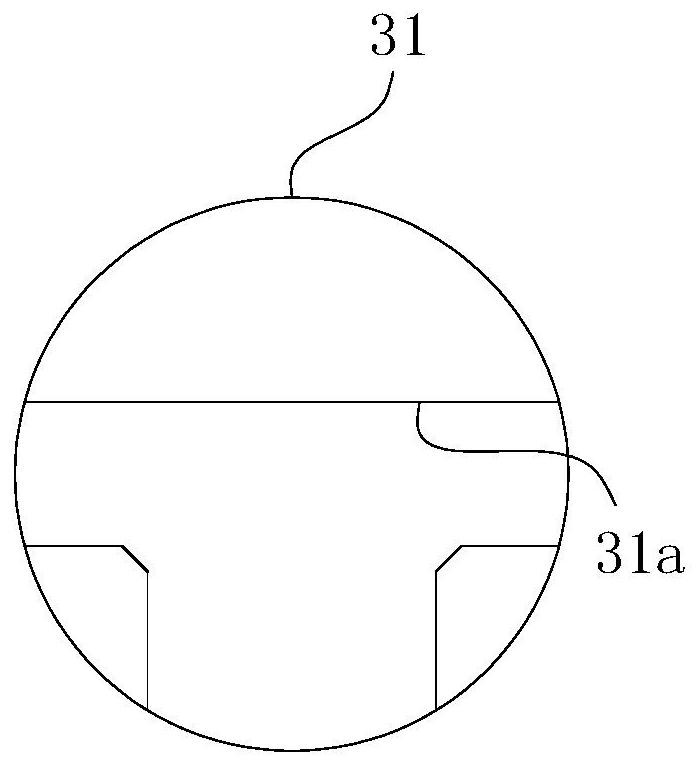

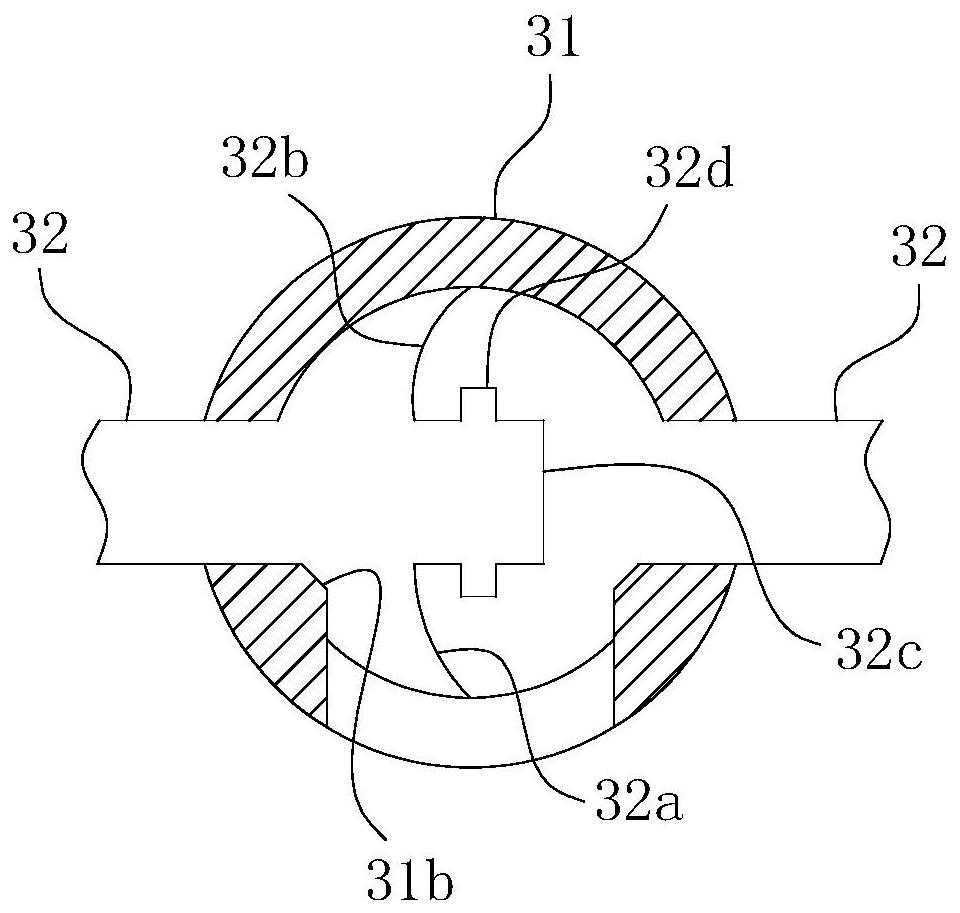

[0038] For ease of understanding, combined here Figure 1-6 , the concrete structure and working mode of the present invention are further described as follows:

[0039] The specific structure of the upper floor anti-shock device used in the present invention is as follows: Figure 1-6 As shown, its main body includes a fixed hoop 10 , a support rod 20 and a support surface 30 arranged sequentially from bottom to top. exist Figure 1-4 and Figure 5-6 In the two groups of embodiments shown, the fixed hoops 10 are all in the shape of a "C" hoop, and the support rods 20 can also purchase telescopic rod structures on the market; the difference between the two groups of embodiments lies in the difference in the number of support rods 20 and the Differences in the configuration of the support surface 30 . in:

[0040] At once Figure 1-4 In the illustrated embodiment, the supporting surface 30 is formed by two hinged rods 32 together with a protective cloth 33 . Protective c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com