Assembly type ditch digging and land leveling device

A prefabricated, leveling technology, applied in the direction of excavation/covering of trenches, planting methods, transportation and packaging, etc., can solve the problems of uneven soil, affecting the effect of gully, and the efficiency and effect of ditching are not ideal, so as to reduce the Clean up work, easy to use and efficient, flexible and convenient selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

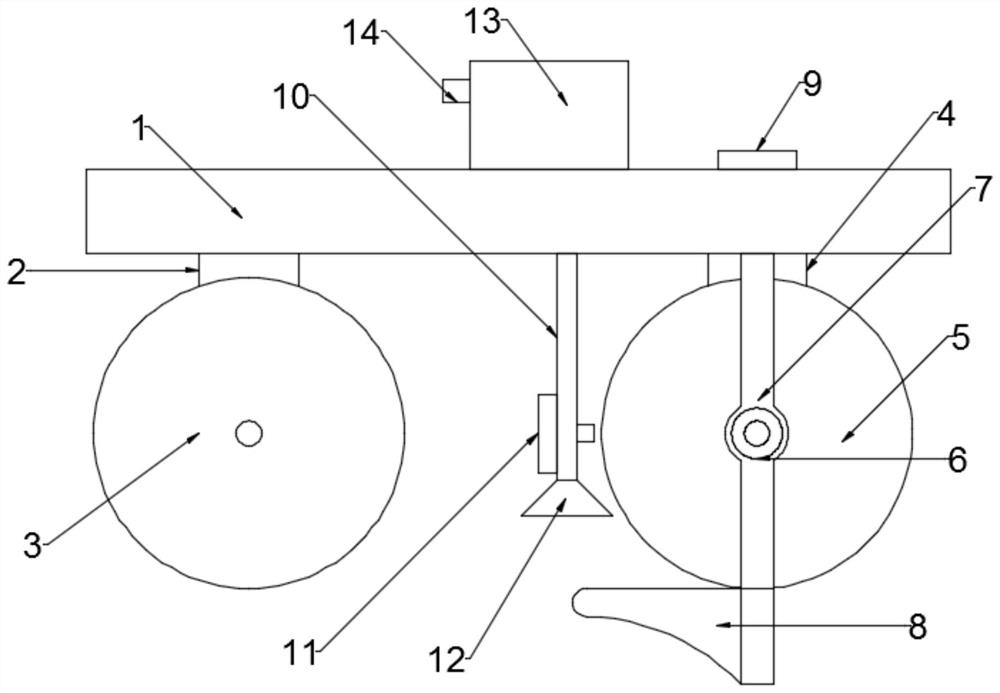

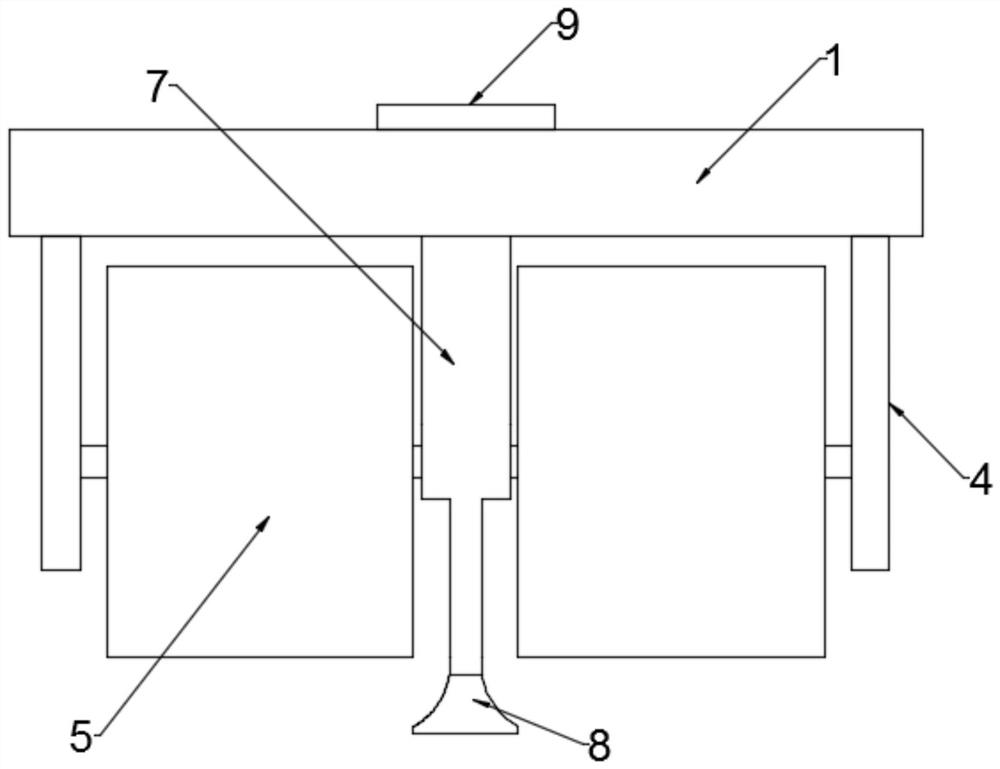

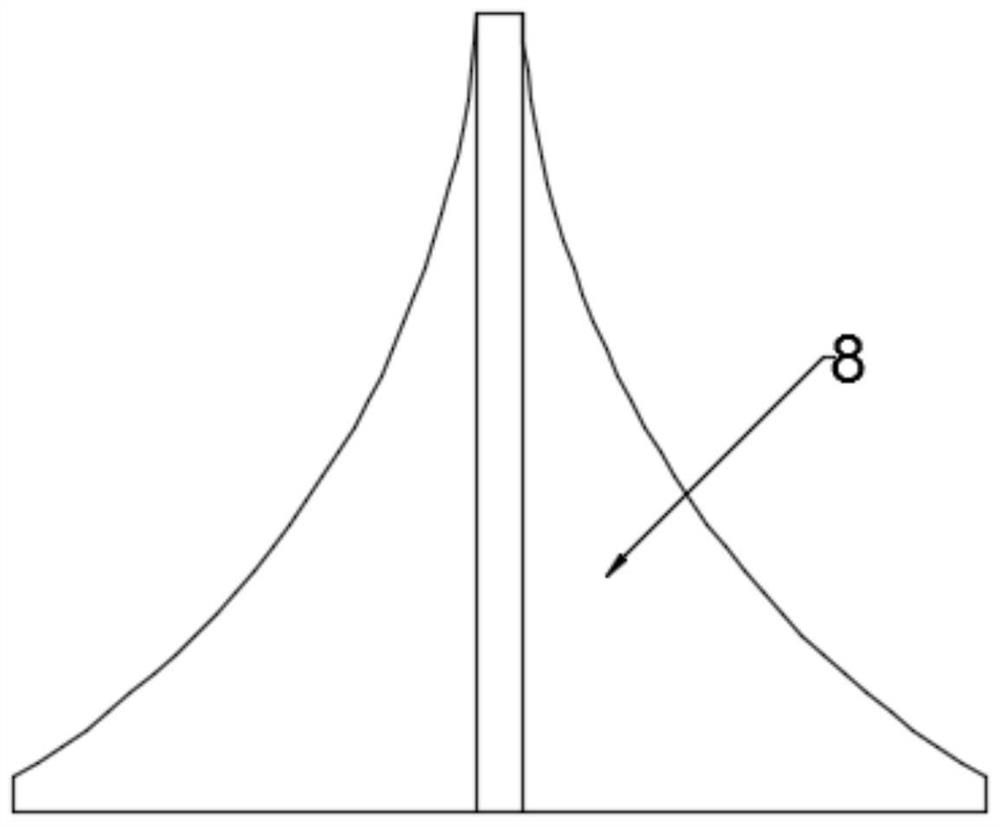

[0024] see Figure 1~4 , in an embodiment of the present invention, an assembled ditching leveling device includes a placement plate 1, and a first bracket 2 and a second bracket 4 are symmetrically connected to both sides of the lower end of the placement plate 1, and on the first bracket 2 A first milling shaft 3 is provided for rotational connection, and a second milling shaft 5 is provided for rotational connection on the second support 4, and a ditching mechanism is provided for a coaxial rotational connection on the second milling shaft 5, and the ditching mechanism One end is detachably connected to the limit mechanism, the lower end of the placement plate 1 is fixedly connected to the side of the second roller shaft 5 and is provided with a vertical plate 10, and the lower end of the vertical plate 10 is opposite to the ditching mechanism. A dust collection cover 12 is provided. The dust collecting hood 12 is connected with a dust collecting mechanism through a pipelin...

Embodiment 2

[0032] see Figure 5 , in an embodiment of the present invention, an assembled ditching and leveling device, on the basis of Embodiment 1, the dust collection mechanism includes a dust storage chamber 13 and an air pump 14, and the air pump 14 is fixedly connected to the dust storage chamber 13- In the upper part of the side, the air intake end of the air pump 14 is connected with the dust storage chamber 13, and a filter cloth is inlaid at the communication position, and the dust storage chamber 13 is located in the air pump 14 air intake end and is radially connected and arranged. There is a rotating shaft 16, and the periphery of the rotating shaft 16 is equiangularly connected with multiple groups of fan blades 17, the ends of the fan blades 17 are connected with bristles, and the filter on one side of the fan blades 17 and the side of the dust storage chamber 13 The cloth is movable and fitted, and the lower end of the dust storage chamber 13 is connected with a dust guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com