Roller gap adjusting mechanism of coating machine

A technology of adjusting mechanism and machine roller, applied in the direction of coating, device for coating liquid on the surface, etc., can solve the problems of inconvenient operation, increased investment cost, difficult adjustment, etc., and achieves convenient operation, high precision and flexible adjustment means. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

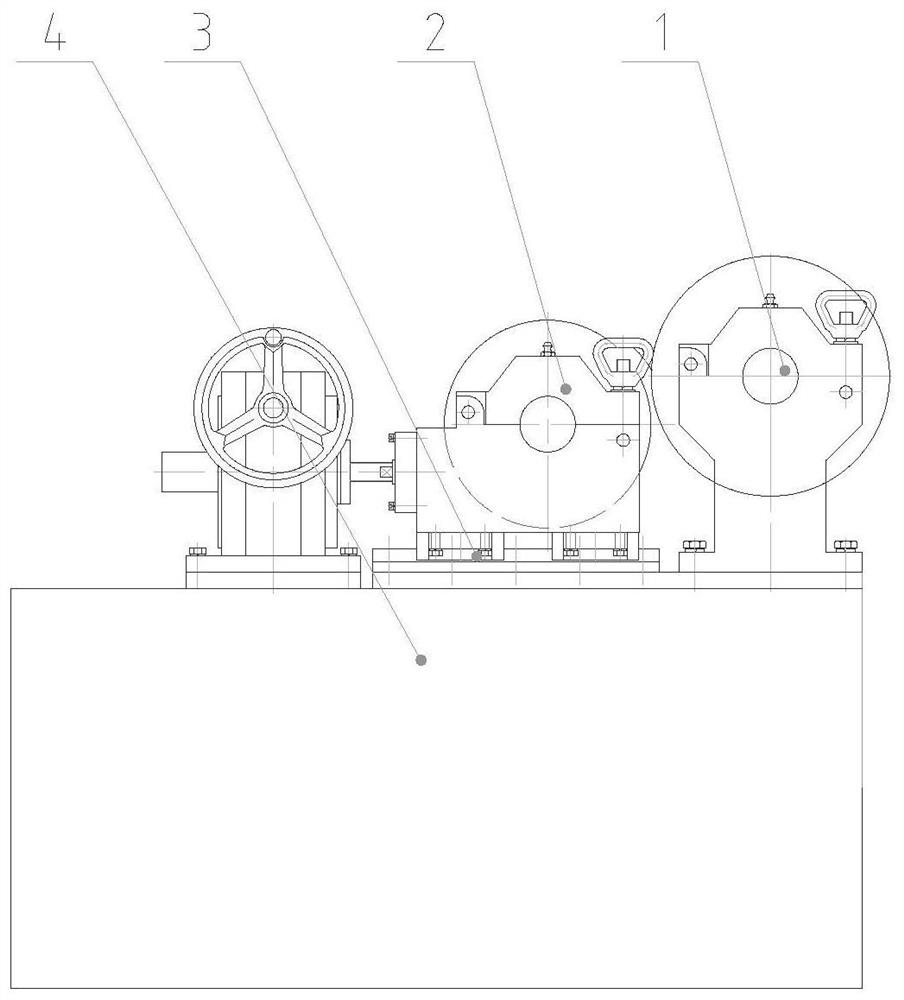

[0025] refer to Figure 1 ~ Figure 4 A coating machine roll gap adjustment mechanism shown includes a coating roller 1, a pick-up roll 2, a pick-up roll bearing seat, a linear guide rail pair 3, a frame 4 and a coating machine roll gap adjustment unit; the coating roll 1 , the linear guide rail pair 3 and the roller gap adjustment part of the coating machine are all connected on the frame 4, and the linear guide rail pair 3 is arranged between the coating roller 1 and the roller gap adjustment part of the coating machine; the pick-up roller 2 passes through the pick-up roller The bearing seat is movably connected to the linear guide pair 3, and the operating side and the driving side of the pick-up roller 2 are respectively connected to the roller gap adjustment part of the coating machine; the coating roller 1 and the pick-up roller 2 are arranged in parallel.

[0026] In actual use, by adjusting the roller gap adjustment part of the coating machine, the pick-up roller bearin...

Embodiment 2

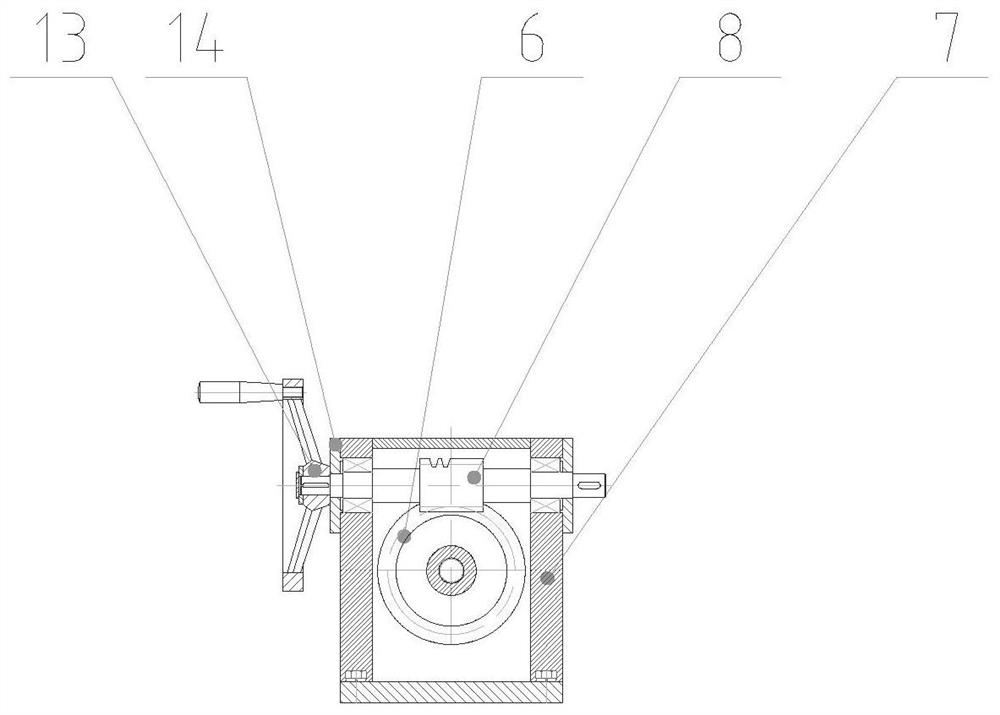

[0029] refer to figure 1 with Figure 4 The roll gap adjustment mechanism of the coating machine shown is based on the first embodiment: the roll gap adjustment part of the coating machine includes two adjustment units, two flange sleeves 15 and a flange connection shaft 16; The two ends of the flange connection shaft 16 are respectively connected to the adjustment unit through the flange sleeve 15; The operation side and the transmission side of the connection.

[0030] In actual use, the flange sleeve 15 is connected to the worm shaft 8 through a key, and the flange sleeve 15 acts as an intermediate transition, connecting the flange connection shaft 16 and the worm shaft 8. At the same time, the flange sleeve 15 and the flange connection shaft 16 There are elongated holes, which can be slightly adjusted for easy connection when connecting. Finally, the roller gap on both sides can be adjusted synchronously.

Embodiment 3

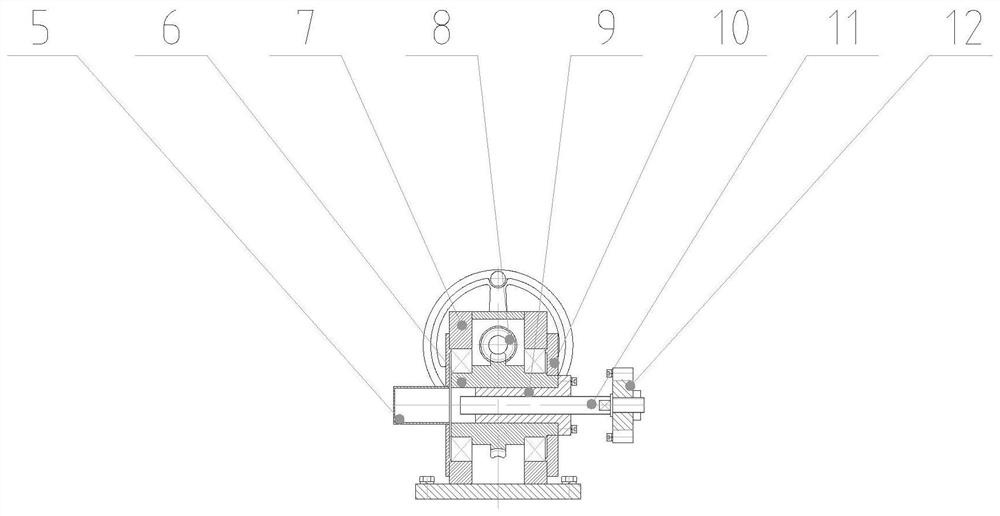

[0032] refer to Figure 1 ~ Figure 3 A coating machine roll gap adjustment mechanism shown is based on the second embodiment: the adjustment unit includes a turbine 6, a box body 7, a worm shaft 8, a drive nut 9, a lead screw 11, and a dynamometer block 12 and drive portion; the box 7 is fixedly connected to the frame 4, the turbine 6 is connected in the box 7; the worm shaft 8 is rotatably connected to the box 7 and the two ends of the worm shaft 8 Extending to the outside of the casing 7, the worm shaft 8 is meshed with the upper part of the turbine 6; the transmission nut 9 is connected to the end face of the turbine 6; one end of the screw 11 is threaded with the transmission nut 9, and the other end of the screw 11 passes through The dynamometer block 12 is connected to the pick-up roller bearing seat; the driving part is arranged outside the box body 7 and connected to one end of the worm shaft 8 .

[0033] Preferably, the driving part is a manual wheel 13 .

[0034] W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com