Multifunctional ceramic tile turning machine tray rack

A pallet rack and multi-functional technology, which is applied in the field of brick turning machines, can solve the problems of complicated and locked procedures of mobile brick turning machines, and achieve the effect of saving time, labor costs and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

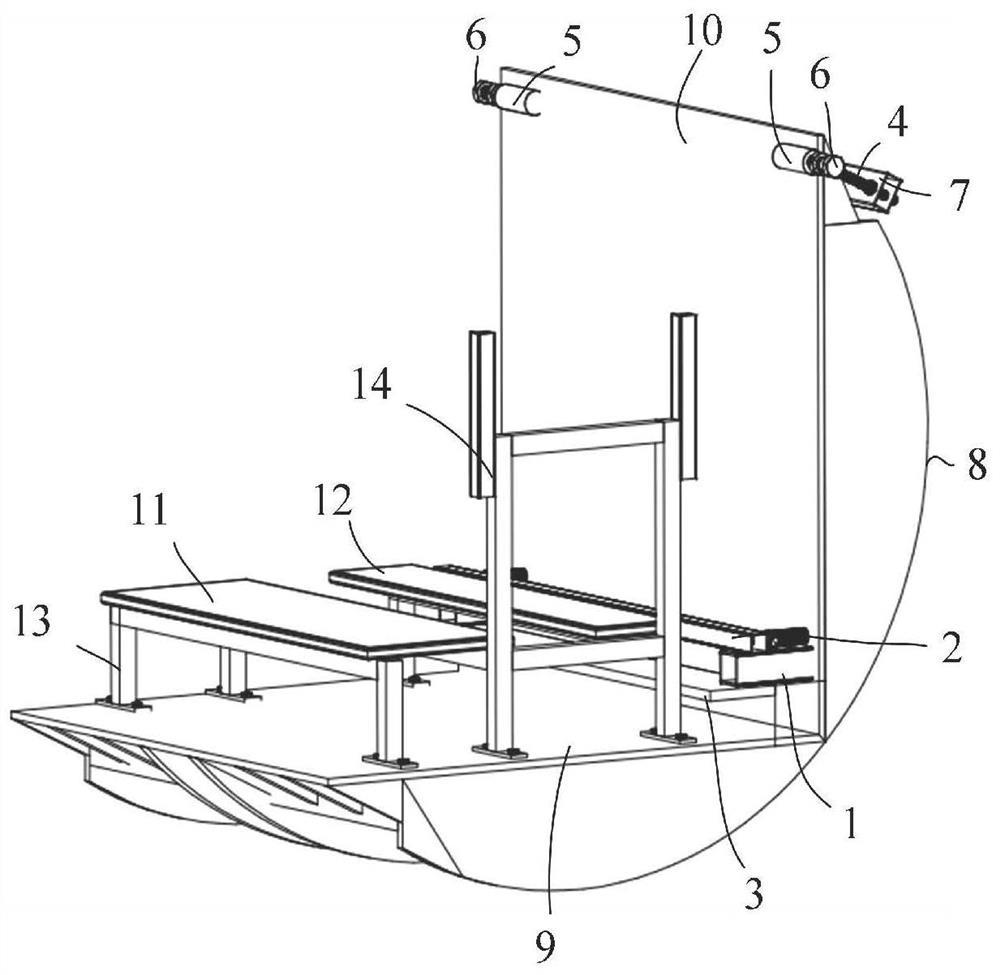

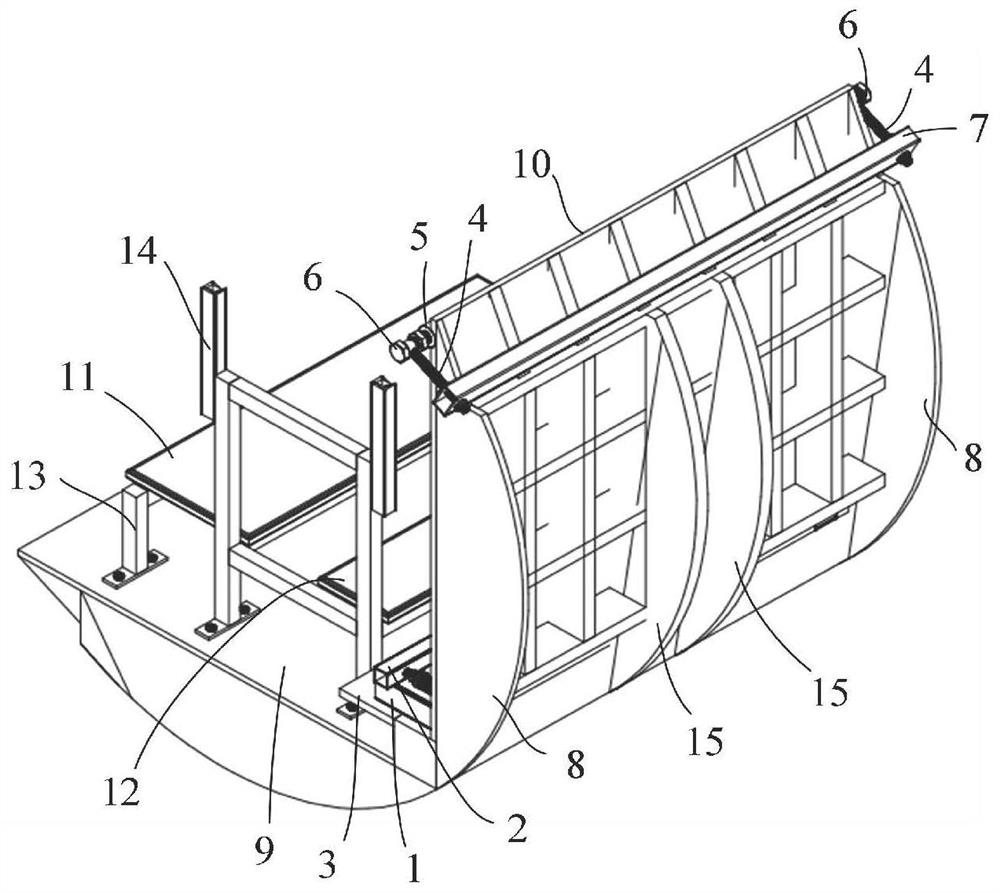

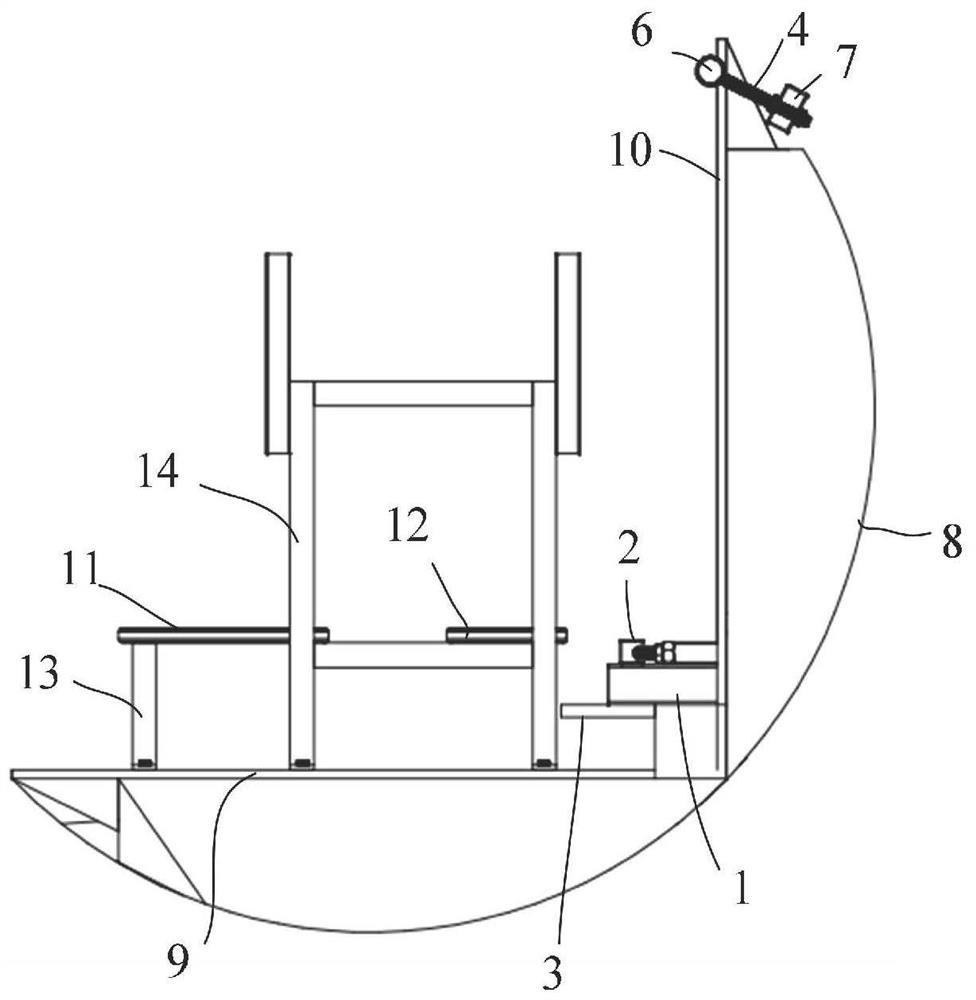

[0028] Such as Figure 1 to Figure 6 As shown, a pallet frame for a multi-functional ceramic brick turning machine in this embodiment includes a pallet frame body, a fixed stroke bracket 1, a horizontal movable stroke load-bearing bracket 2, a longitudinal movable stroke supporting plate 3, and a rotating movable rocker 4 , fixed support bar 5, load-bearing bar 6 and swing bar 7, pallet frame body has the base plate 9 of horizontal arrangement and the riser 10 of vertical arrangement, the junction of base plate 9 and riser 10 is fixed with fixed travel bracket 1, horizontal The movable stroke load-bearing bracket 2 is installed on the upper part of the fixed stroke bracket 1, the longitudinal movable stroke bracket 3 is installed on the lower part of the fixed stroke bracket 1, and the upper ends of the two vertical edges of the riser 10 are respectively fixed with fixed support rods 5 Each fixed support rod 5 is provided with a load-bearing rod 6, one end of the rotating mova...

Embodiment 2

[0032] Such as Figure 1 to Figure 6 As shown, a multi-functional ceramic brick turning machine tray frame in this embodiment includes all the technical features in Embodiment 1. In addition, a horizontally extending strip groove is provided on the fixed stroke bracket 1, and the strip The extending direction of the shaped groove is perpendicular to the vertical plate 10, and the lower surface of the laterally movable stroke load-bearing bracket 2 is fixed in the strip shaped groove by bolts.

[0033] Specifically, the load-bearing bracket 2 of the laterally movable stroke of the present embodiment is made of a rectangular steel pipe, and the lower end surface of the load-bearing bracket 2 of the laterally movable stroke is welded with two screw rods, and the vertical side of the load-bearing bracket 2 of the laterally movable stroke is passed through the screw. Connect the sleeves welded horizontally on the riser 10.

[0034] The beneficial effect of this embodiment is that ...

Embodiment 3

[0036] Such as Figure 1 to Figure 6 Shown, a kind of multi-functional ceramic brick turning machine tray frame in the present embodiment includes all the technical characteristics in embodiment 2, besides, the load-bearing rod 6 is a bolt, and the load-bearing rod 6 is threaded on the fixed support rod 5 Inside.

[0037] Specifically, the rotating movable rocker 4 includes a rotating screw and a rotating nut. One end of the rotating screw is welded with a rotating nut.

[0038] The beneficial effects of this embodiment are: by setting the load-bearing rod 6 as a bolt, its adjustment in the fixed support rod 5 is realized, and by setting the rotating screw rod, the adjustment of the distance between the swing rod 7 and the load-bearing rod 6 is realized, thereby When the swing bar 7 is rotated to one side of the vertical plate 10, the distance between the load-bearing bracket 2 and the vertical plate 10 in the lateral movement is ensured to be equal to the distance between th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap