Nonlinear damping vibration isolator, floating slab with nonlinear damping vibration isolator and floating slab track system

A vibration isolator and non-linear technology, applied in the field of track vibration and noise reduction, can solve problems such as increased track structure displacement, potential safety hazards of train operation, and reduced vibration impact, achieving good vibration and noise reduction performance, simple and reliable structure , weaken the effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

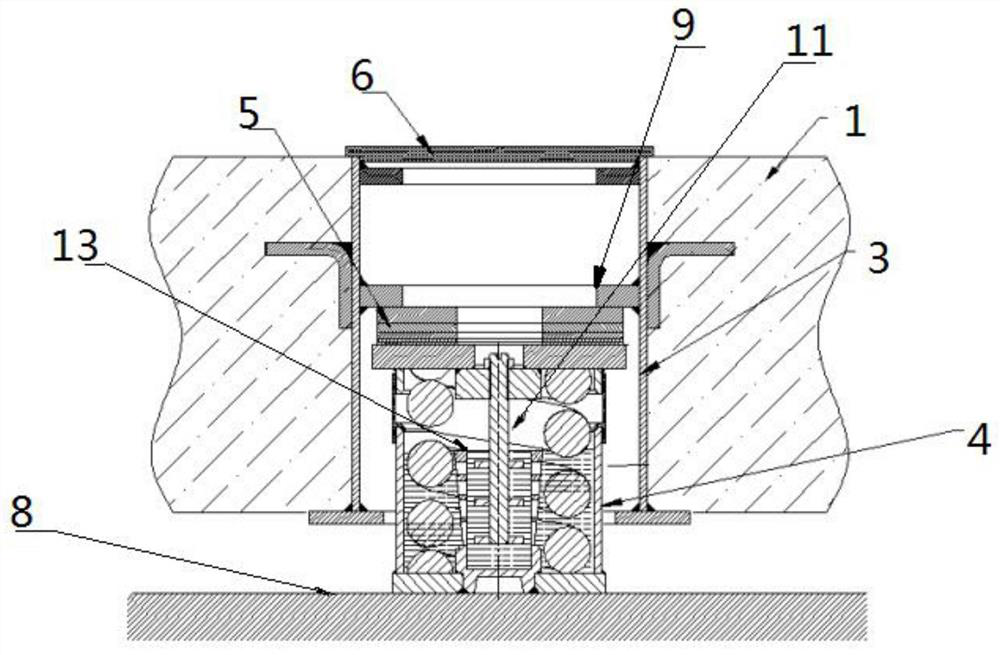

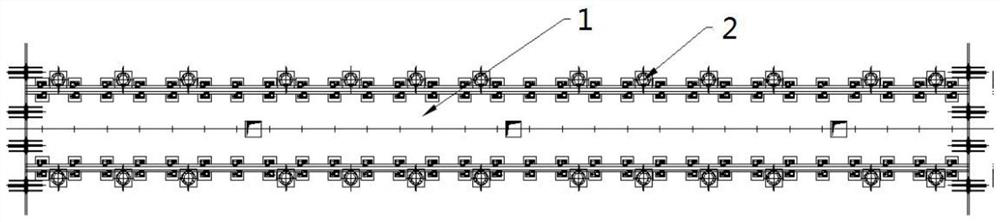

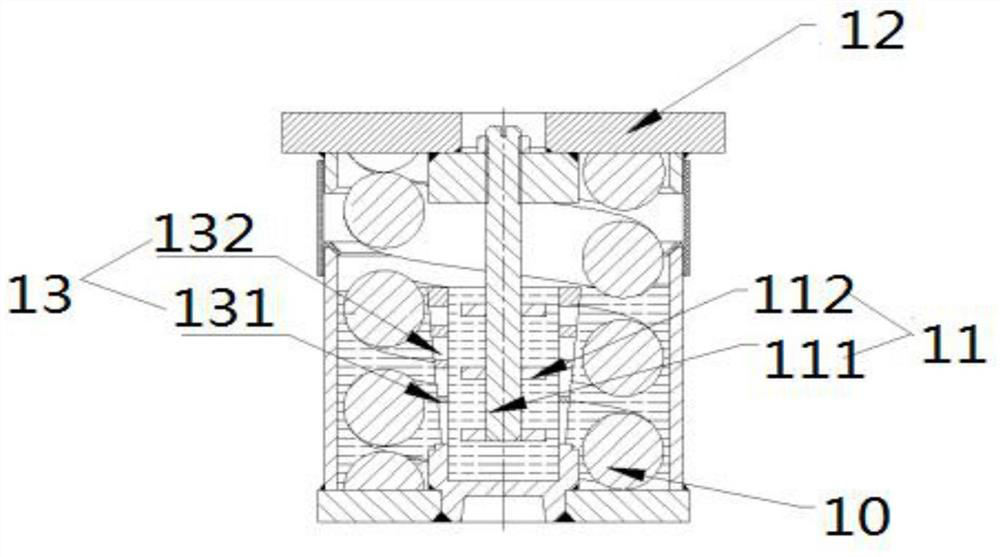

[0034] Refer to the attached Figures 1 to 8 , according to an embodiment of the present invention, a nonlinear damping vibration isolator for installation in the floating plate 1, the nonlinear damping vibration isolator 4 includes a fixed part, and the fixed part includes a base 14, a damping cylinder part 13 and a sleeve 15 , the damping cylinder part 13 is fixed in the middle of the base 14; the sleeve 15 is correspondingly located outside the damping cylinder part 13 and fixed along the peripheral side of the base 14;

[0035] The moving part, the moving part includes a top cover 12, a steel spring 10 and a damping piston 11. The top cover 12 is located above the sleeve 15 and is connected with the upper end of the sleeve 15 through a sealing member 16; the steel spring 10 is sleeved on the damping cylinder part 13 Between the sleeve 15 and its upper and lower ends correspond to the top cover 12 and the base 14; one end of the damping piston 11 is fixed to the top cover 1...

Embodiment 2

[0044] When the peripheral diameter of cylinder body 131 gradually increases from top to bottom, the diameter of the corresponding damping hole 132 on cylinder body 131 decreases from top to bottom, and damping chamber B is formed in damping cylinder part 13, and steel spring 10 A damping gap C is formed in the damping liquid between the cylinder 131 and the sleeve 15. When the top cover of the vibration isolator moves down, it drives the damping piston 11 to move down. Since the outer diameter of the cylinder 131 increases gradually from top to bottom Therefore, the damping gap C between the steel spring 10 and the cylinder 131 decreases gradually, the relative flow rate of the damping fluid decreases gradually, the corresponding damping force and damping coefficient increase relatively, and the diameter of the damping hole 132 changes from above to It decreases successively from bottom to bottom, so when the damping piston 11 moves downward, the relative flow rate inside and ...

Embodiment 3

[0046] When the peripheral diameter of the cylinder 131 increases first and then decreases from top to bottom, the corresponding aperture diameter of the damping hole 132 on the cylinder 131 decreases first and then increases from top to bottom, and the inside of the damping cylinder 13 is formed In the damping chamber B, the steel spring 10 forms a damping gap C in the damping liquid between the cylinder 131 and the sleeve 15. When the top cover of the vibration isolator moves down, it drives the damping piston 11 to move down. Due to the outer diameter of the cylinder 131 From top to bottom, it first increases and then decreases. Therefore, the damping gap C between the steel spring 10 and the cylinder 131 first gradually decreases and then gradually increases. The relative flow rate of the damping fluid first gradually decreases and then gradually increases. increases, the corresponding damping force and damping coefficient first increase and then decrease, and the diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com