Large-diameter straight pipe pressure balance type expansion joint balanced by adopting external external-pressure corrugated pipe

A technology for pressing bellows and bellows, which is applied in the field of pressure-balanced expansion joints for large-diameter straight pipes. The effect of production quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

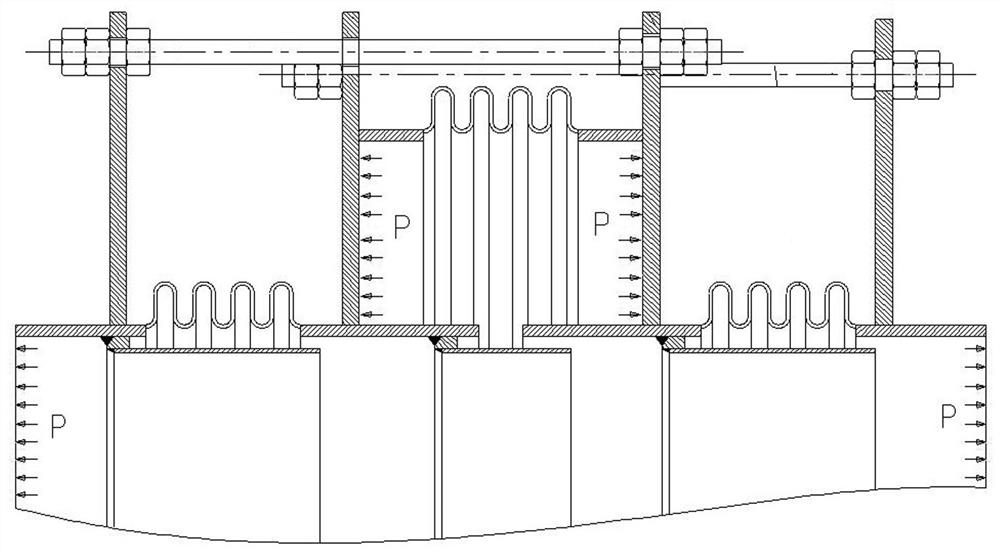

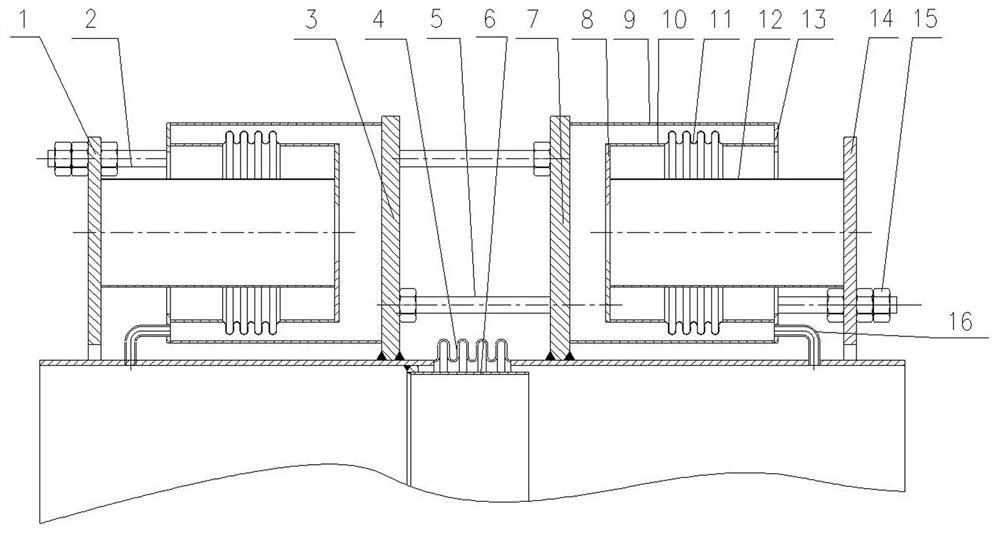

[0034] A large-diameter straight pipe pressure-balanced expansion joint with external external pressure bellows balance is used, and a working bellows 4 is provided. There are two end pipes connected to the two sides of the working bellows 4, and the outer sides of the end pipes on both sides are along the circumferential direction. There are multiple sets of tie rod assemblies 18 and multiple sets of peripheral bellows balance assemblies. The diameter of the working bellows 4 located in the center is much lower than the diameter of the original balance wave, and the overall outer diameter of the peripheral bellows balance components 19 arranged in multiple groups is also lower than the diameter of the original balance bellows.

[0035] Multiple groups of peripheral bellows balance components 19 are evenly distributed on the circumference of each end pipe, and the peripheral bellows balance components 19 are composed of a guide plate, an end ring, a force transmission cylinder ...

Embodiment 2

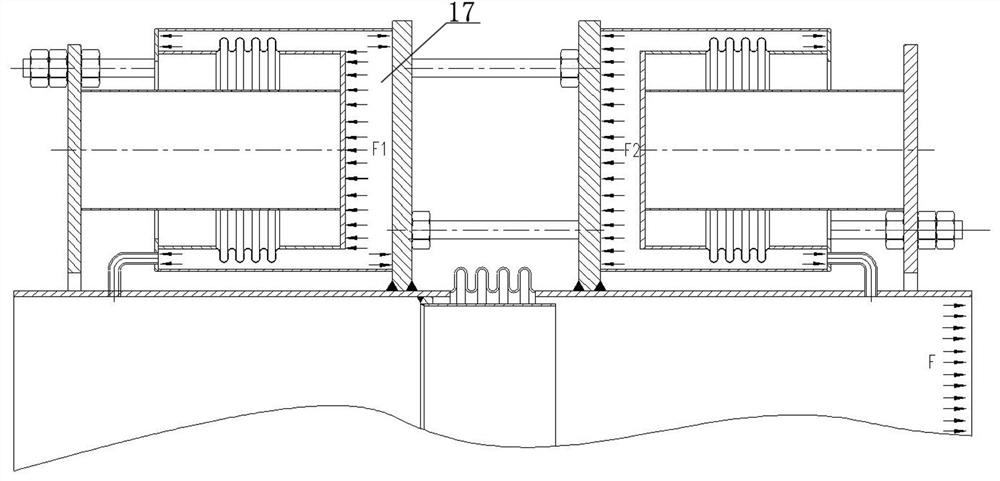

[0037] Such as Figure 6 , Figure 7 As shown in , in order to reduce the force arm of the end pipe assembly (the distance from the tie rod hole to the pipe), thereby reducing the bending stress and deformation deflection of the root weld of the end pipe assembly, and optimizing its stress state, a tie rod is set inside the external bellows Bellows, which play the role of medium sealing and isolating the tie rods, the peripheral bellows, tie rods, and the axes of the tie rods are coaxial, which can reduce the force of the tie rods on the bending arm of the end pipe assembly as a whole, and optimize its stress state and structural deformation , Reduce material consumption. The peripheral balance mechanisms on both sides of the working bellows are staggered to arrange the tie rods, and the bellows of the tie rods are displaced in the inner cavity of the outer bellows, which can reduce the axial length of the expansion joint as a whole.

[0038] On the basis of Example 1, an op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com