Optical system subassembly for automobile lighting

A technology for optical systems and automotive lighting, applied in the field of optical system sub-assemblies, can solve problems such as cumbersome assembly, and achieve an effect that is conducive to rapid assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

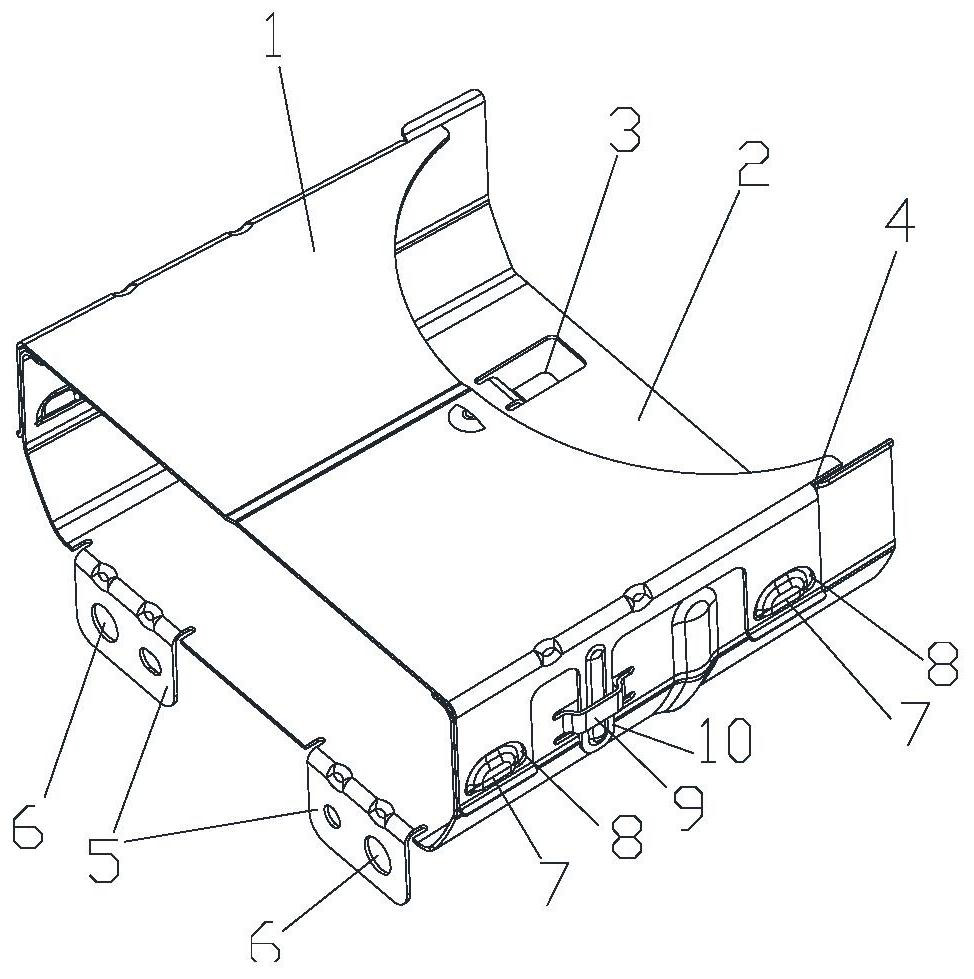

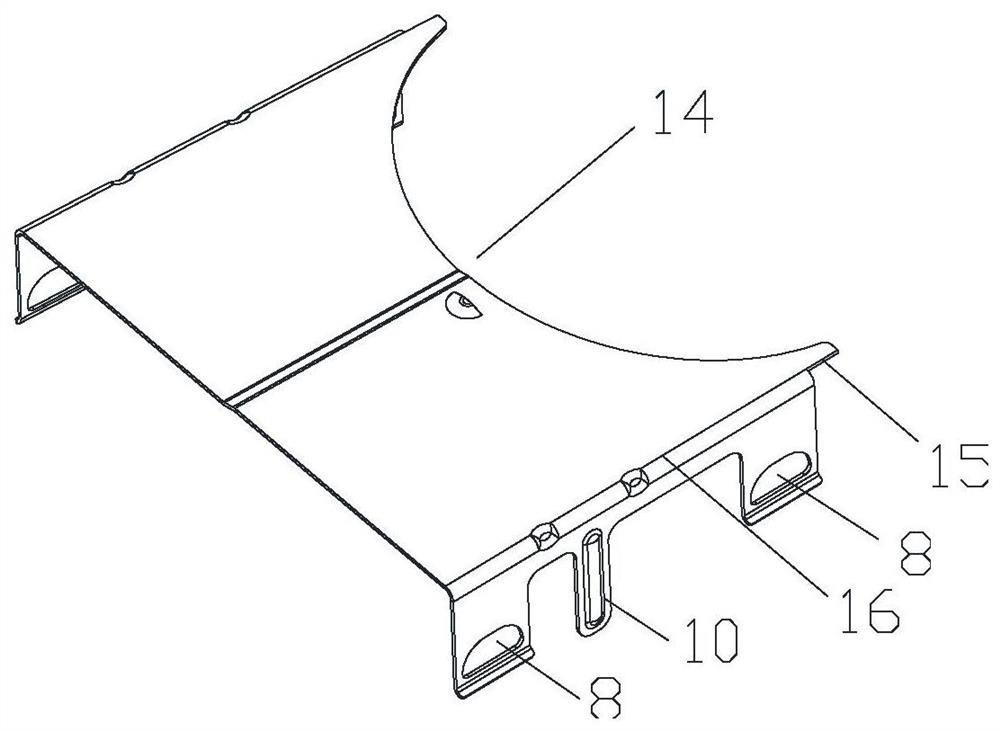

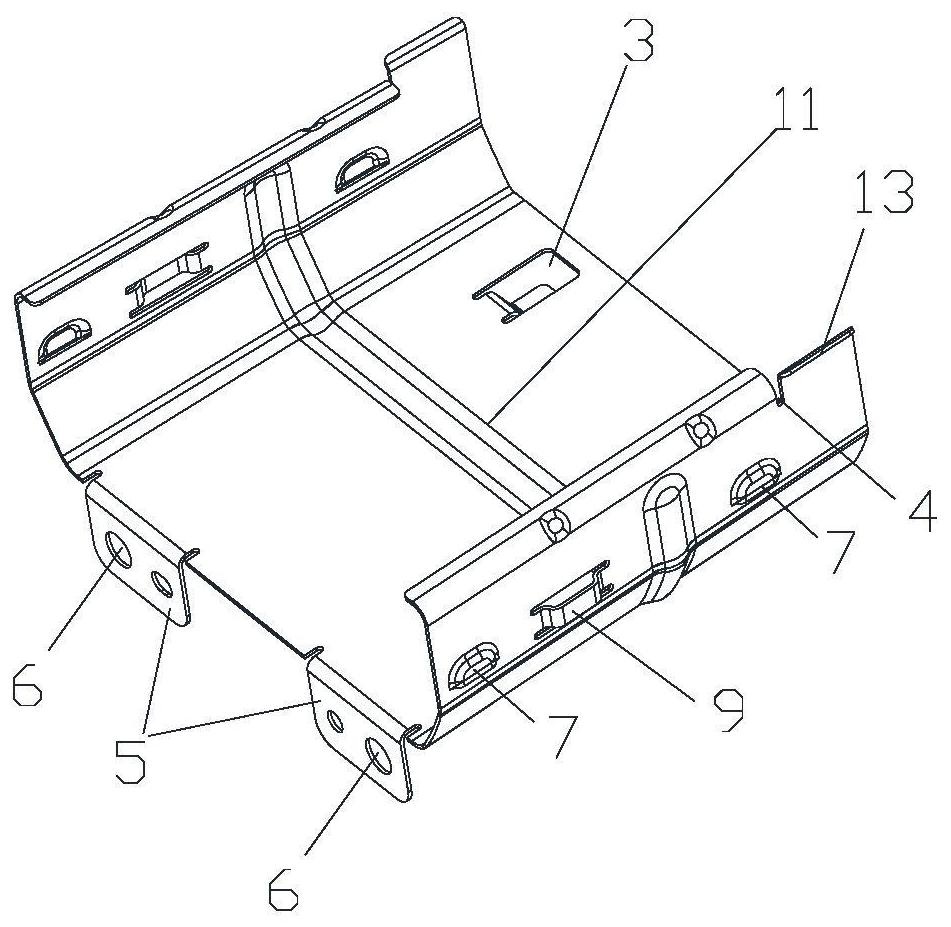

[0017] Such as figure 1 As shown, an optical system sub-assembly for automotive lighting includes a shutter 2 and a baffle 1 horizontally arranged above the shutter 2, and the baffle 1 is connected to the baffle 1 through a snap-fit structure. connect. Such as figure 2 and 3 As shown, the clamping structure includes several slots 8 and plugs 10 arranged on the baffle 1, and the shutter 2 is provided with a stamping bridge 9, and the stamping bridge 9 cooperates with the plug 10 to perform Position limit, the shutter 2 is provided with a number of transoms 7, and the transoms 7 are snapped together with the card slots 8. The baffle plate 1 is clamped with the shutter 2, which is convenient for disassembly and assembly.

[0018] Such as image 3 As shown, the two sides of the shutter 2 are bent and extended inwardly to form a mounting surface 12, and the remaining part forms a limiting surface 13. The limiting surface 13 is located at one end of the mounting surface 12, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap