Water-cooled motorcycle water pump installation structure

An installation structure and motorcycle technology, applied to pumps, parts of pumping devices for elastic fluids, pump components, etc., can solve the problems of reducing pump water volume, press-fitting quality affecting sealing performance, water nozzle leakage, etc., to achieve Reduce water flow energy loss, facilitate rapid assembly, and avoid water leakage from the faucet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

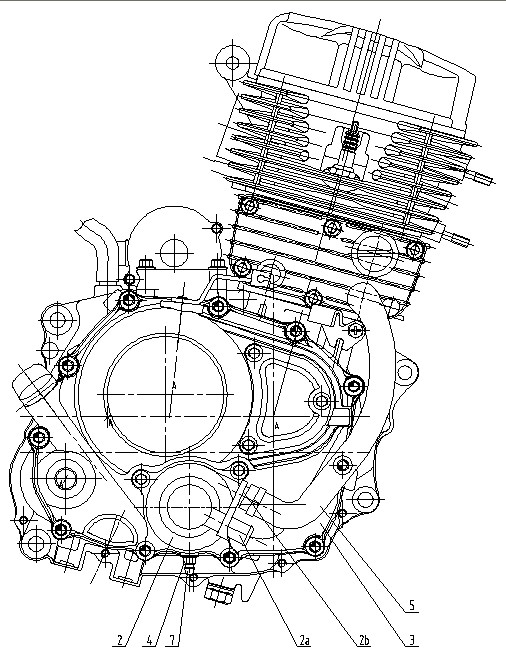

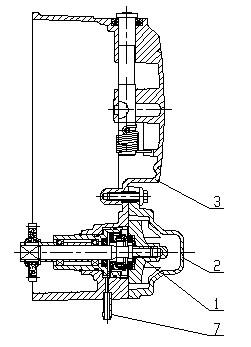

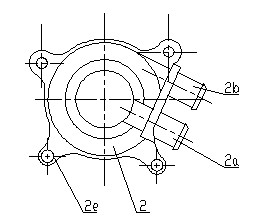

[0025] Such as figure 1 , figure 2 Shown, the present invention has water pump and right crank case cover 3 two major parts, and wherein water pump is made of impeller assembly 1 and water pump cover 2. A positioning hole is provided in the middle of the lower part of the right crankcase cover 3, and the impeller assembly 1 is installed at the positioning hole. The impeller assembly 1 includes components such as an impeller, a water pump shaft, a transmission gear, a bearing, a sealing ring, and the connection relationship of each component. It is the same as the prior art and will not be repeated here. The transmission gear in the impeller assembly 1 meshes with the clutch driven gear, and the clutch driven gear drives the water pump to work. An overflow pipe 7 is installed at the bottom of the right crankcase cover 3, and the overflow pipe 7 communicat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap