Motion conversion device and slicing machine thereof

A conversion device and movement technology, applied in the direction of measuring device, sampling device, sampling, etc., can solve the problems of laborious operation and low production efficiency of structural parts, and achieve the effect of solving laborious operation and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

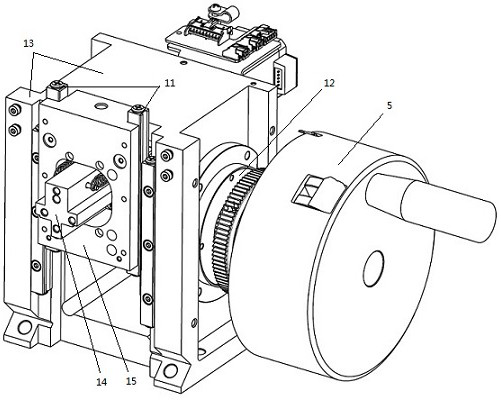

[0021] figure 2 It is a schematic diagram of the motion conversion device provided by the embodiment of the present invention. Such as figure 1 with figure 2 As shown, the motion conversion device includes a guide rail 11 , a drive shaft 12 , a main frame 13 , a sample injection main machine 14 and a slider 15 . The motion conversion device is included in the main body 1 .

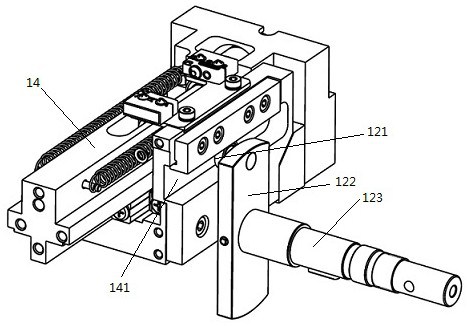

[0022] In the embodiment of the present invention, a handwheel 5 is installed at one end of the driving shaft 12 , and the other end passes through the main frame 13 and is connected with the sample injection main machine 14 . Sampling host 14 is connected with main frame 13 by guide rail 11 and slide block 15, and slide block 15 is fixed together with the base (not shown in the figure) in the main frame 13; The position of the sampling host 14 is relatively fixed, that is, the positions of the slider 15 and the sampling host 14 are relatively fixed. A sample positioning device 2 (not shown in the f...

Embodiment 2

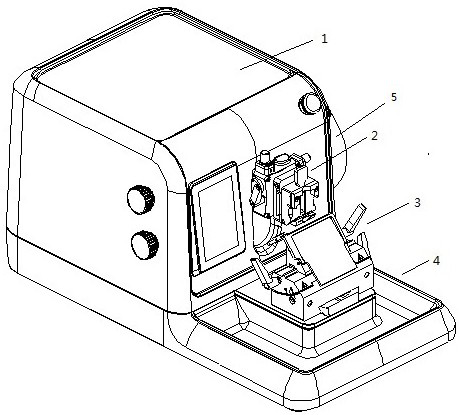

[0028] Such as figure 1 with figure 2 As shown, the embodiment of the present invention provides a slicer, including a main body 1 , a sample positioning device 2 , a knife holder 3 , a collection tray 4 and a hand wheel 5 . The main body 1 includes the motion conversion device as described in the first embodiment.

[0029] For the convenience of operation, in the embodiment of the present invention, the hand wheel 5 is arranged at one end of the drive shaft 12 and exposed to the main body 1 .

[0030] In the embodiment of the present invention, the main frame is connected to the main unit of sample injection through guide rails and sliders, and the main unit of sampling injection is connected to the drive shaft through chute and ring, so that the rotational motion of the drive shaft is converted into the reciprocation of the main unit of sampling injection. Linear motion; and the cooperation between the chute and the ring has low requirements on the processing technology a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com