Middle section method uniaxial compression reading auxiliary device and using method thereof

A technology of uniaxial compression and auxiliary devices, applied in the direction of measuring devices, adopting mechanical devices, mechanical measuring devices, etc., can solve problems such as insufficient accuracy, difficult measurement, and influence on modulus test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

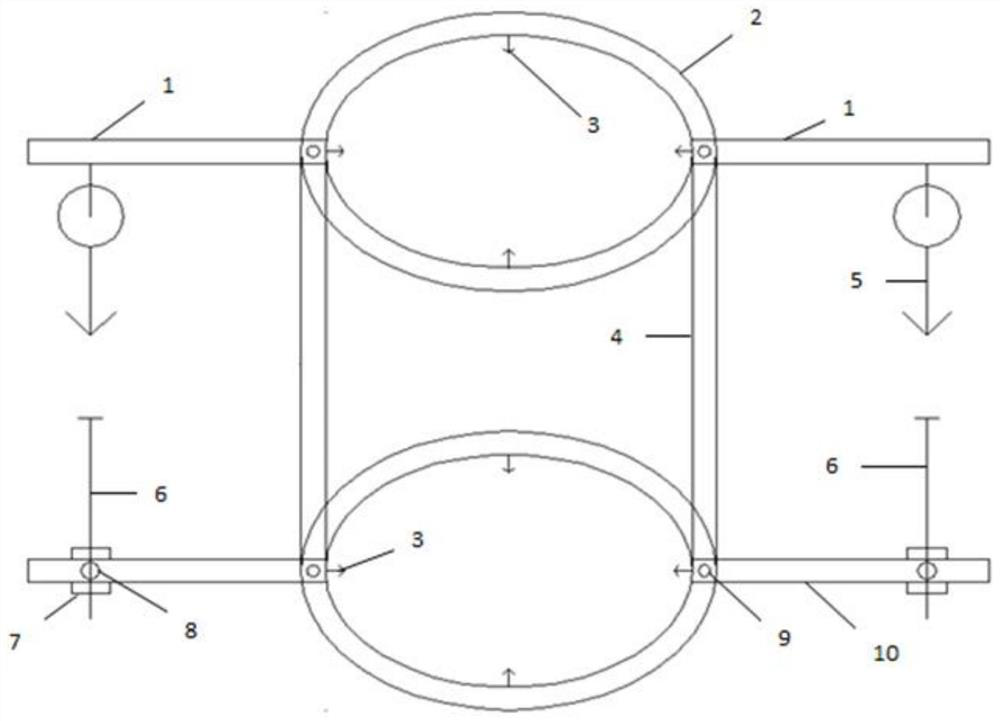

[0022] see figure 1 , an auxiliary device for uniaxial compression reading in the middle section method includes an upper elongated square rod, a collar, a built-in screw, a fixed vertical plate, a dial gauge, a flat head screw, a nut, a screw hole, a fixed knob, and a lower elongated square rod. pole.

[0023] The collar includes an upper and lower annular collar, with 4 built-in screws, arranged at an angle of 90 degrees, with the tip of the screw facing inward, for being set on a cylindrical sample and fixed on the sample.

[0024] One end of the lower elongated square rod is fixed to the collar through the knob, which can rotate freely along the plane, and the other end is provided with a screw hole for placing the flat-head screw. Through the design of the upper and lower nuts, the flat-head screw can be reasonably fixed and ensured. The upper end of the square rod has sufficient screw length so that the dial indicator can touch its surface and be read.

[0025] The fix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com