Counterweight hot-line work maintenance vehicle

A technology for live work and maintenance vehicles, which is applied in the direction of overhead lines/cable equipment, hoisting devices, hoisting devices, etc. It can solve the problems of only applying for power outages, pulley pulleys, deflection wheels, and endangering the safety of operators, etc., to achieve the design Reasonable, high safety and reliability, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the above-mentioned features and advantages of the present invention easier to understand, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

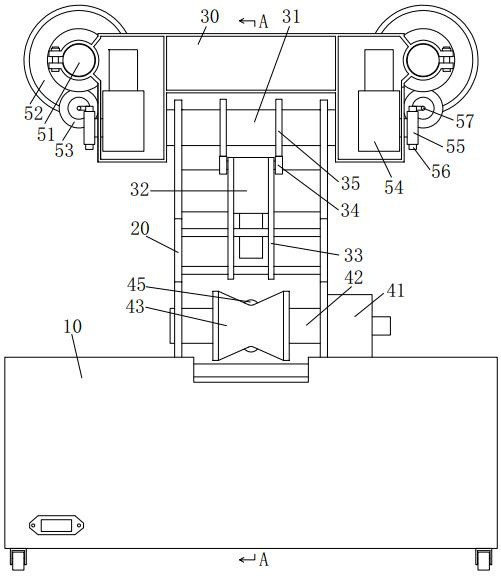

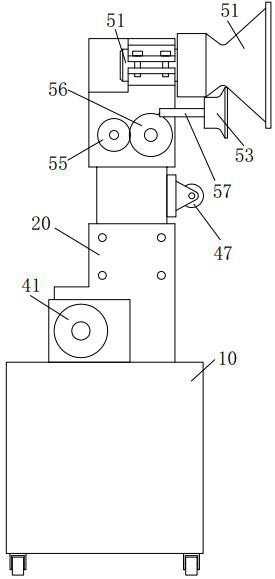

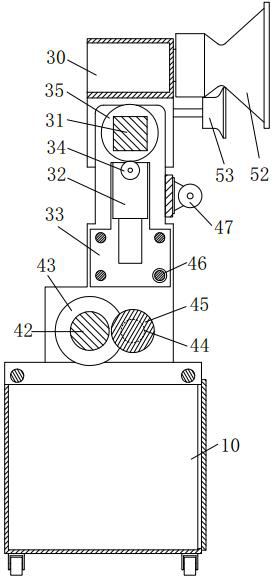

[0025] refer to Figure 1 to Figure 4

[0026] A counterweight live working maintenance vehicle, including a counterweight box 10 that can prevent the counterweight inside, so as to increase the weight of the counterweight box according to the use requirements, the counterweight box is provided with a support frame 20, and the support frame is provided with a movable The climbing mechanism that climbs up through the insulating rope, the upper end of the support frame is provided with a mounting frame 30 that is driven and rotated by the driving mechanism, and the two sides of the mounting frame are respectively provided with wires that are clamped and walked through the wire after the mounting frame rotates. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com