A continuous stamping die for winding stator core

A technology for stamping dies and stator iron cores, which is used in the manufacture of stator/rotor bodies, etc., can solve the problems of reducing the production efficiency of stator iron cores, discontinuous production process, etc., and achieves a simple structure, high adaptability, and guaranteed product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

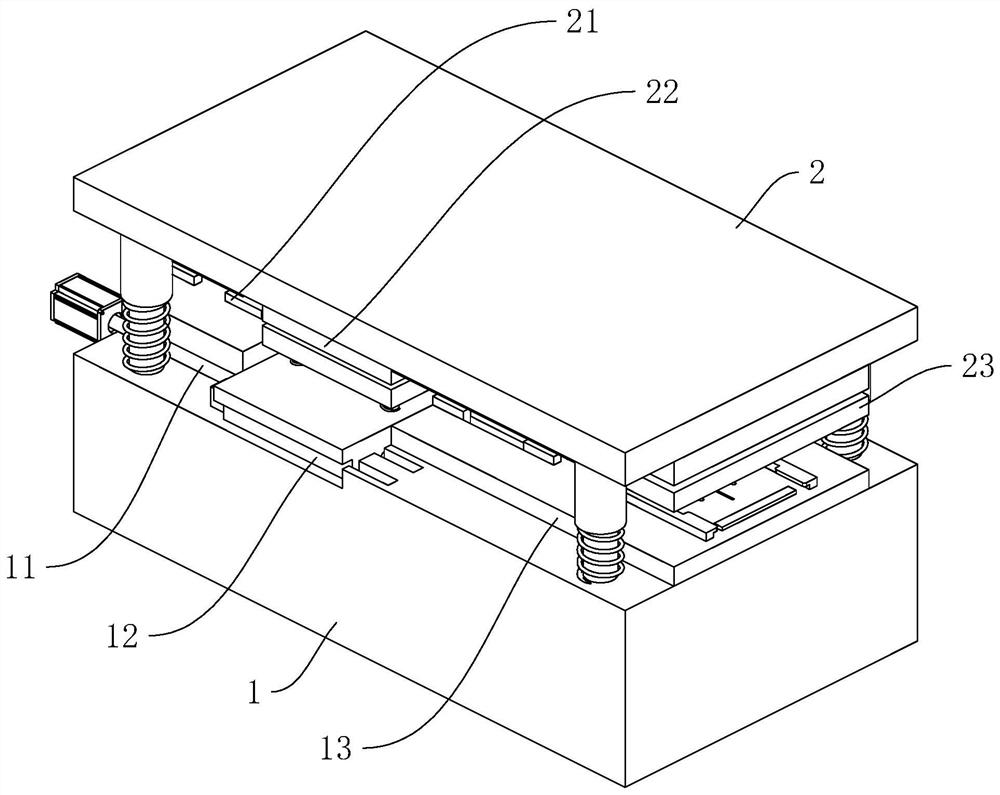

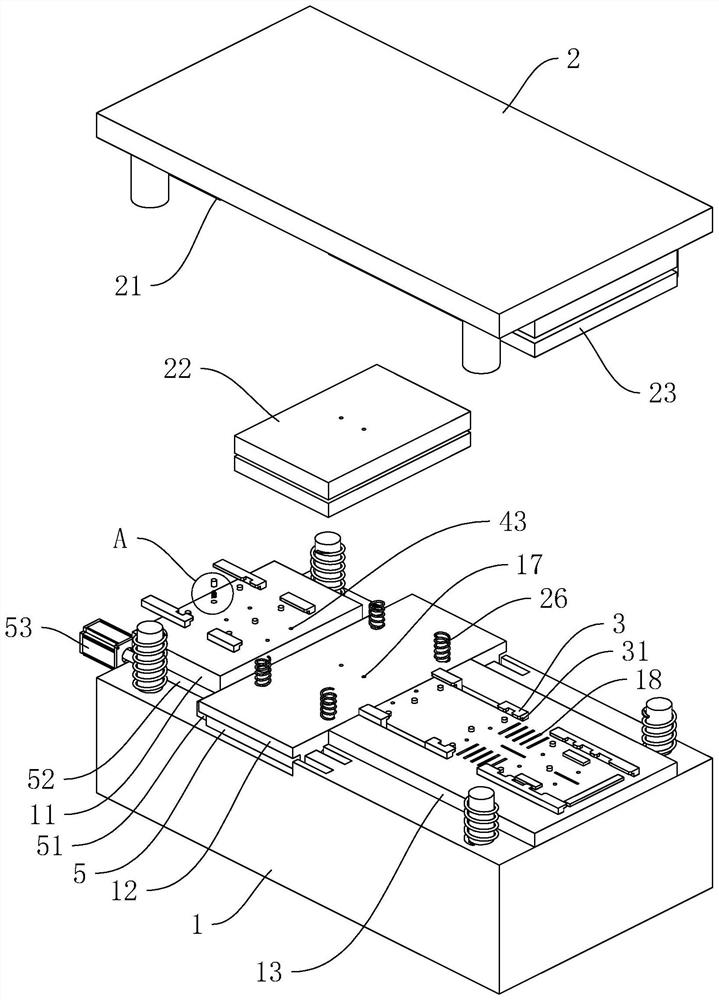

[0040] Embodiment 1: as figure 1 , figure 2 As shown, a continuous stamping die for a winding stator core includes a lower template 1 and an upper template 2, and the lower template 1 is sequentially provided with a first fixed mold 11, a second fixed mold 12 and a third fixed mold 13, A first movable mold 21 , a second movable mold 22 and a third movable mold 23 are sequentially arranged on the upper template 2 .

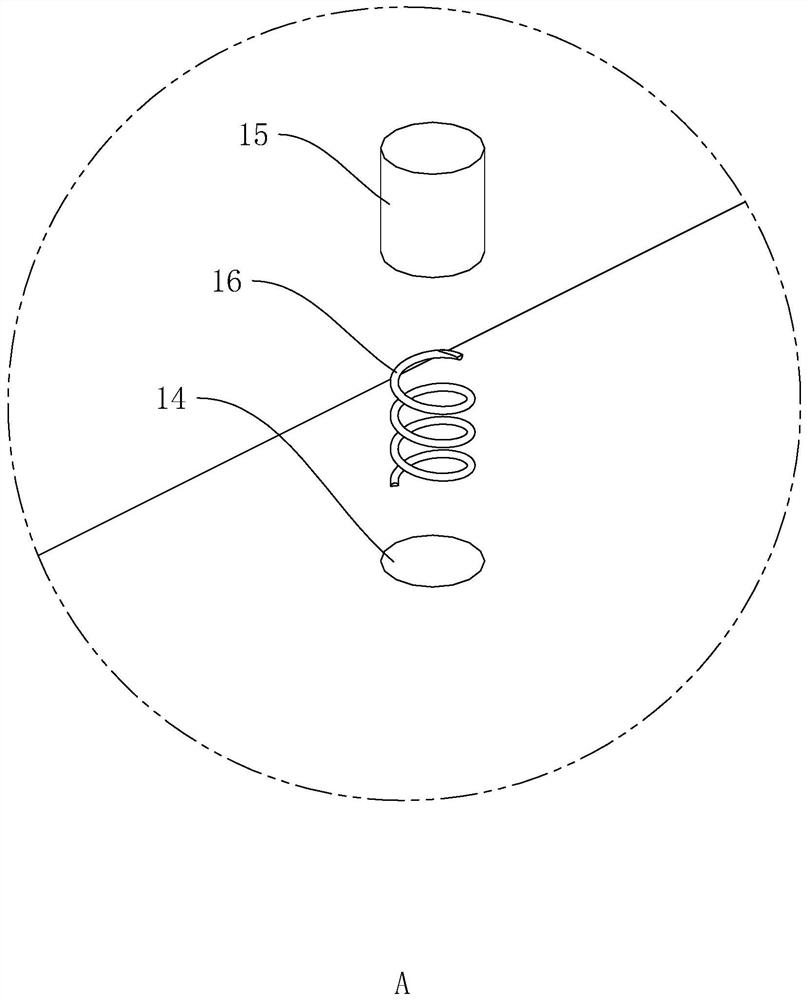

[0041] Such as figure 2 , image 3 As shown, the upper end surfaces of the first fixed mold 11, the second fixed mold 12 and the third fixed mold 13 are distributed with a plurality of sliding holes 14, and the sliding holes 14 are vertically slidably connected with sliding rods for contacting the lower end surface of the iron core band. 15, and a spring 16 is provided between the lower end surface of the sliding rod 15 and the bottom wall of the sliding hole 14.

[0042] Such as figure 2 , Figure 4 As shown, the first movable mold 21 , the second movable...

Embodiment 2

[0053] Embodiment 2: as Figure 5 As shown, the difference from Embodiment 1 is that a support 6 is provided at one end of the lower formwork 1 close to the third fixed form 13 , and a support base 61 is horizontally provided on the support 6 . A cleaning box 7, a flushing box 8, and a drying box 9 are sequentially arranged on the support base 61, and the outer walls of the upper ends of the cleaning box 7, the washing box 8, and the drying box 9 are all provided with through holes 62 for passing through the iron core belt. .

[0054] After the iron core strip is stamped and formed, the iron core strip is usually directly wound to ensure continuous production and processing of the stator iron core. Therefore, after the iron core band is formed, use the cleaning box 7 to clean the impurities on the surface of the iron core band, then use the flushing box 8 to rinse the cleaning solution, and finally use the drying box 9 to dry the water stains on the surface of the iron core b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com