A position calibration method, system and automatic monitoring method

A technology of automatic monitoring and calibration method, applied in the field of control, can solve the problems of masking equipment deterioration trend, reliability risk of calibration function, difficult maintenance, etc., to facilitate equipment maintenance, eliminate the influence of environmental interference, and improve reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

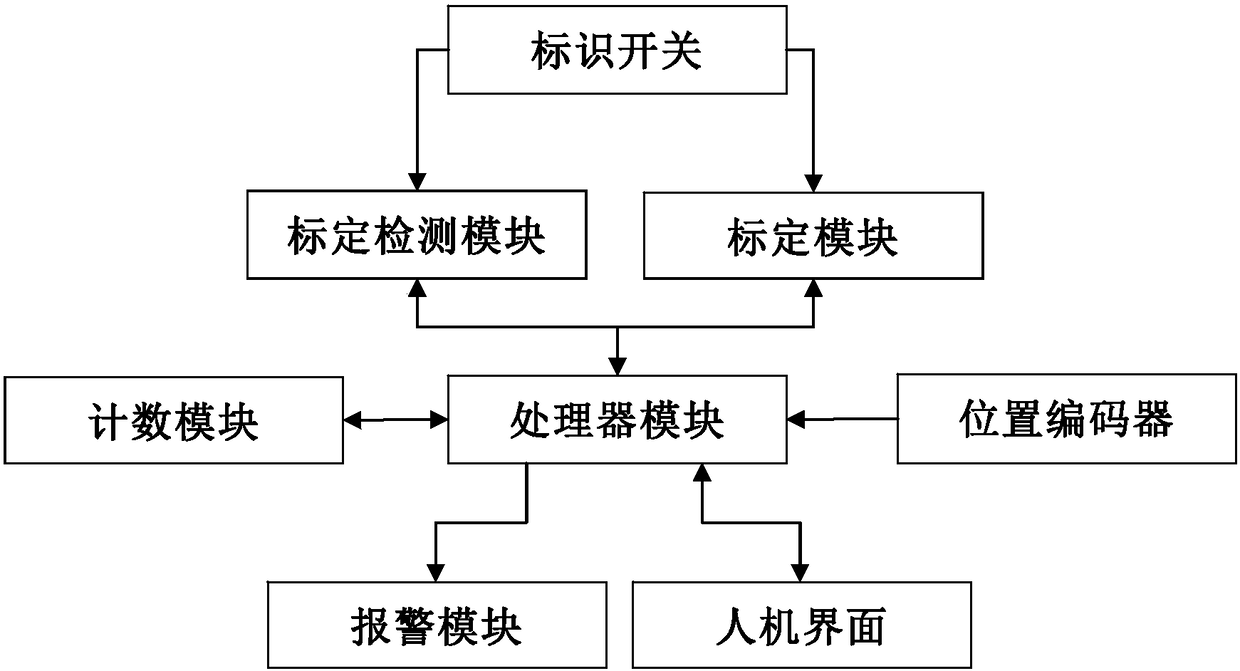

[0050] The embodiment of the present application provides a position calibration method, system, and automatic monitoring method to solve the technical problems that the calibration function itself has reliability risks in the prior art, and at the same time, it will cover up the deterioration trend of the equipment and make maintenance difficult; the calibration has been improved. Functional reliability, at the same time realize the comparative verification of the overall position positioning function, and improve the technical effect of self-detection ability.

[0051] In order to solve the above technical problems, the general idea of the technical solution provided by the embodiment of the present application is as follows:

[0052] An automatic monitoring method for position calibration, which is used to monitor the operation of the position calibration structure; the position calibration structure includes: a position identification switch and a position controller arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com