Pipeline assembly and method of installation

A technology of pipe assembly and pipe assembly, applied in the direction of pipe laying and maintenance, pipe/pipe joint/pipe fitting, pipe, etc., can solve problems such as pipe damage, installation difficulty, and cathodic protection is not absolutely reliable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] While the invention is applicable to any installation from offshore to shoreline, the following examples will refer to drilling platforms.

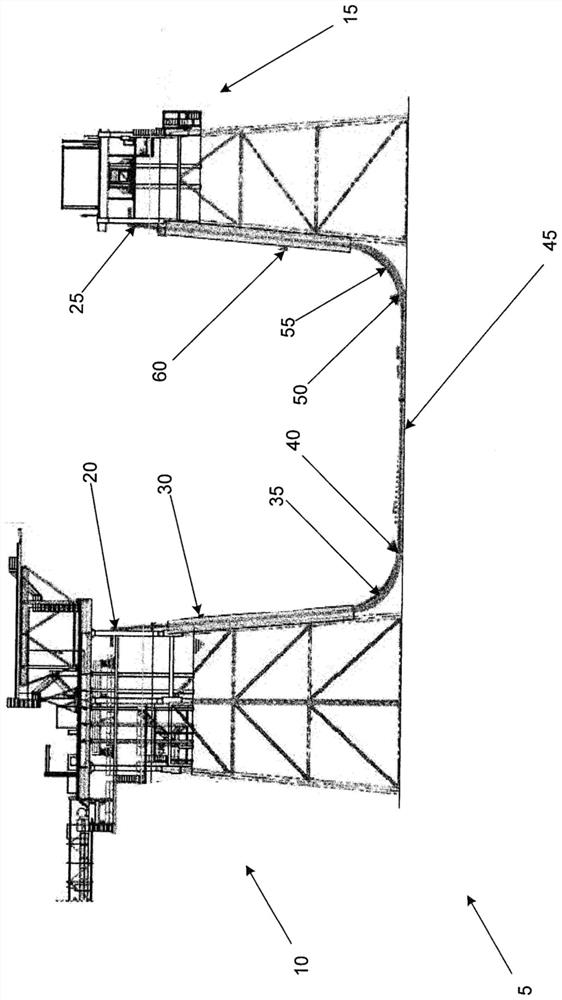

[0012] figure 1 A schematic diagram of the installed pipeline 5 spanning between the first platform 10 and the second platform 15 is shown. The pipe comprises two different types of constructed pipes, a thermoplastic composite pipe (TCP) 40 and a reinforced thermoplastic pipe (RTP) 50 forming a connection 45 .

[0013] The first platform 10 comprises end fittings and hangers 20, 25 to which the pipes are mounted. I-pipes 30, 60 are provided from each rig 10, 15 to guide and point the tubing towards the base of the rig so that the tubing lies across the seabed. In order to obtain the correct curvature as the pipe moves from its roughly vertical position in the I-pipe to its horizontal position laying on the seabed, bend limiters 35, 55 are also provided, thereby controlling the amount of water drawn from each of the rigs. orienta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com