A method for replacing the trunnion bearing on the drive side under abnormal conditions in a steelmaking converter

A technology of trunnion bearings and steelmaking converters, which is applied in the manufacture of converters, metal processing equipment, metal processing, etc., can solve the problems of replacing the trunnion bearings on the transmission side, damage and failure of the trunnion bearings on the drive side of the converter, and achieve a short replacement period , the comprehensive effect is remarkable, the operability effect is strong

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

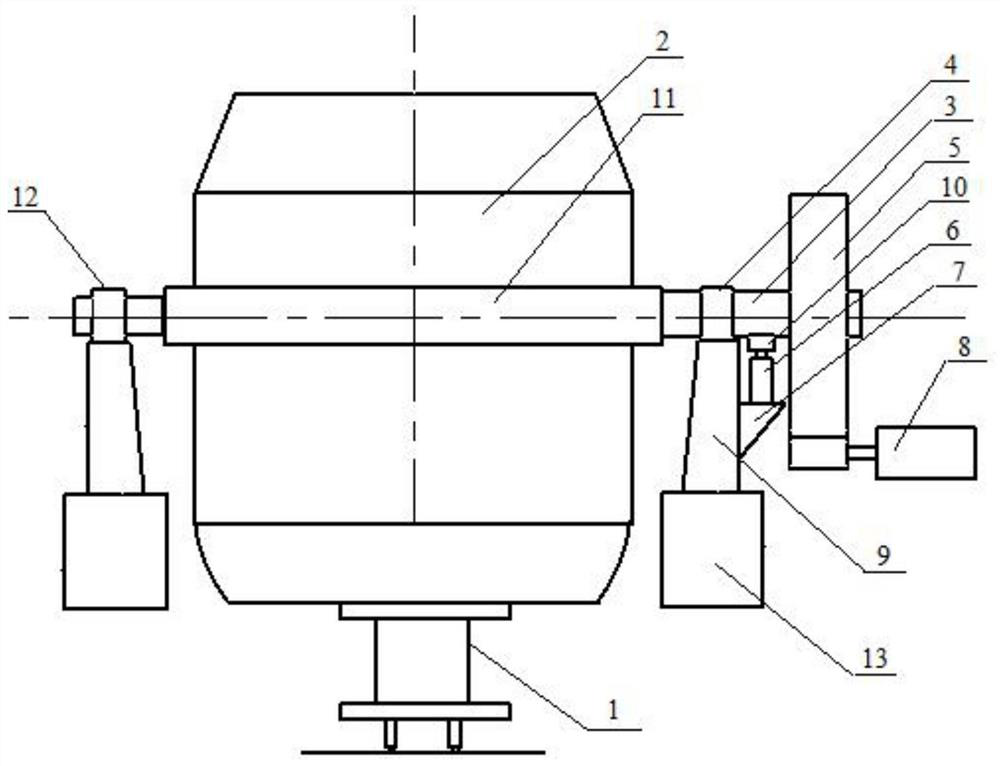

[0031] A method for replacing the trunnion bearing on the drive side under abnormal conditions in a steelmaking converter, such as figure 1 At the bottom of the furnace, the jacking car 1 with a maximum lifting force of 1700kN is used as the first lifting device, and its main function is to lift the furnace shell and lining of the converter 2; the maximum lifting force is 2000kN. Equipment 2, jacking support ring 11 and suspended deceleration large gear 5; use the jacking car 1 and jacking cylinder 6 to work together to lift the trunnion bearing on the drive side of the support ring by 50mm, then disassemble the trunnion bearing 4 on the drive side, The non-side motion bearing 12 must not be lifted in the whole process, and the specific implementation method is as follows:

[0032] 1) Push the jacking car 1 to the bottom of the converter 2. The jacking car 1 includes a base, wheels arranged under the base and hydraulic cylinders arranged on the base, and the center of the hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com