Device and method for improving perpendicularity of pre-embedded screw

A technology of pre-embedded screws and verticality, applied in the field of mechanical processing, can solve the problems of surface flatness of recessed adhesive, affecting product assembly cycle, time-consuming, etc., to avoid multiple rework, good quality and economic benefits, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] This part is the embodiment of the present invention, which is used to explain and illustrate the technical solution of the present invention.

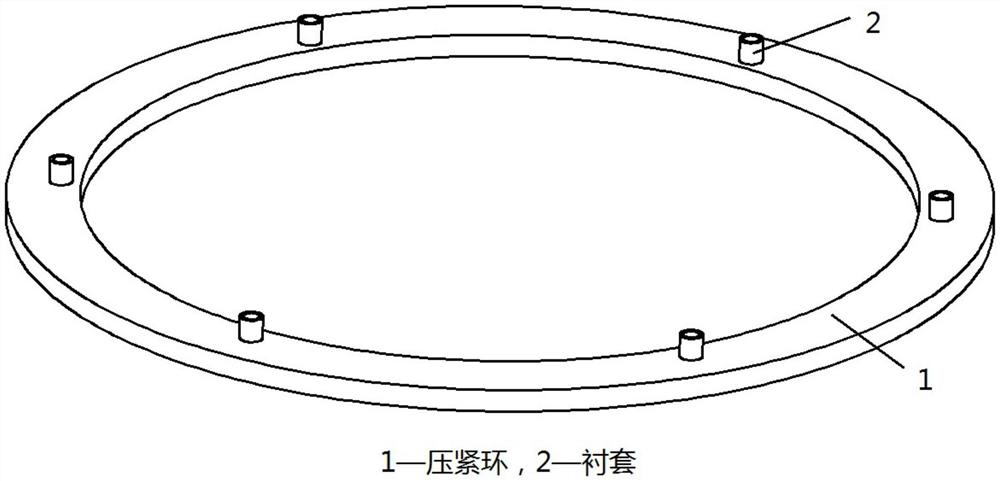

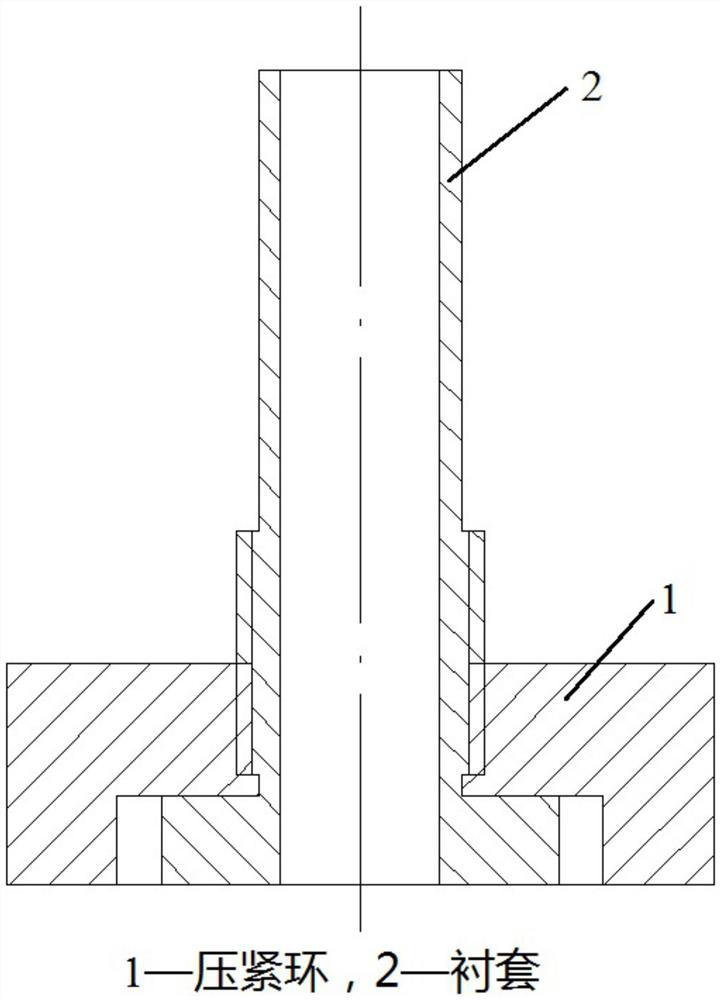

[0025] A device for improving the verticality of pre-embedded screws according to the present invention includes a pressing part 1 and a bushing 2. The pressing part 1 is a structure that matches the plane shape of the area to be processed with adhesive. The pressing part 1 is provided with There are the same number of mounting holes as the embedded screws, the number of bushings 2 is the same as the number of mounting holes, the outer diameter of the bushing 2 matches the outer diameter of the mounting hole, and the inner diameter of the bushing 2 matches the diameter of the screw shaft of the embedded screw.

[0026] Wherein, the mounting hole of the pressing part 1 has an internal thread, the bushing 2 has an external thread, and the internal thread of the pressing part 1 matches the external thread of the bushing 2 . Connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com