Anti-blockage rotary bin

A rotating warehouse and anti-blocking technology, which is applied in the field of warehouses, can solve the problems of poor anti-blocking effect, etc., and achieve the effect of improving stability, flexible rotation, and good anti-blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

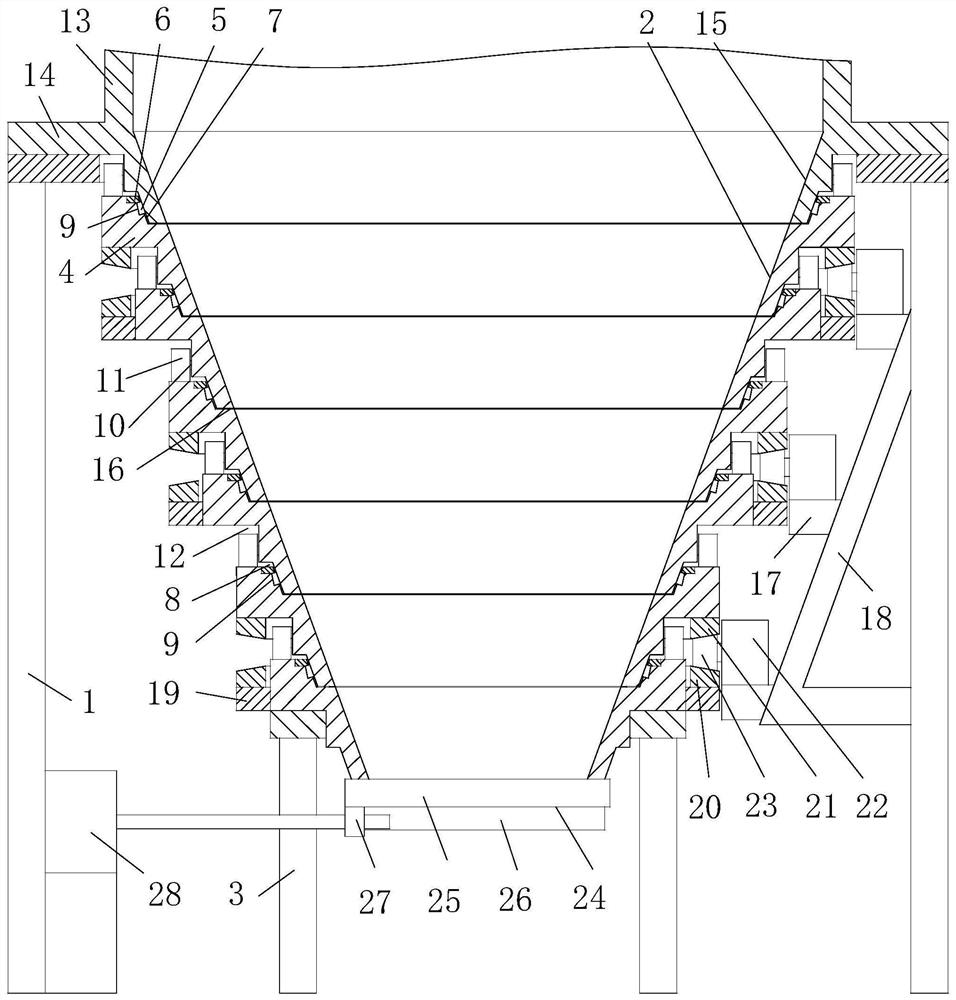

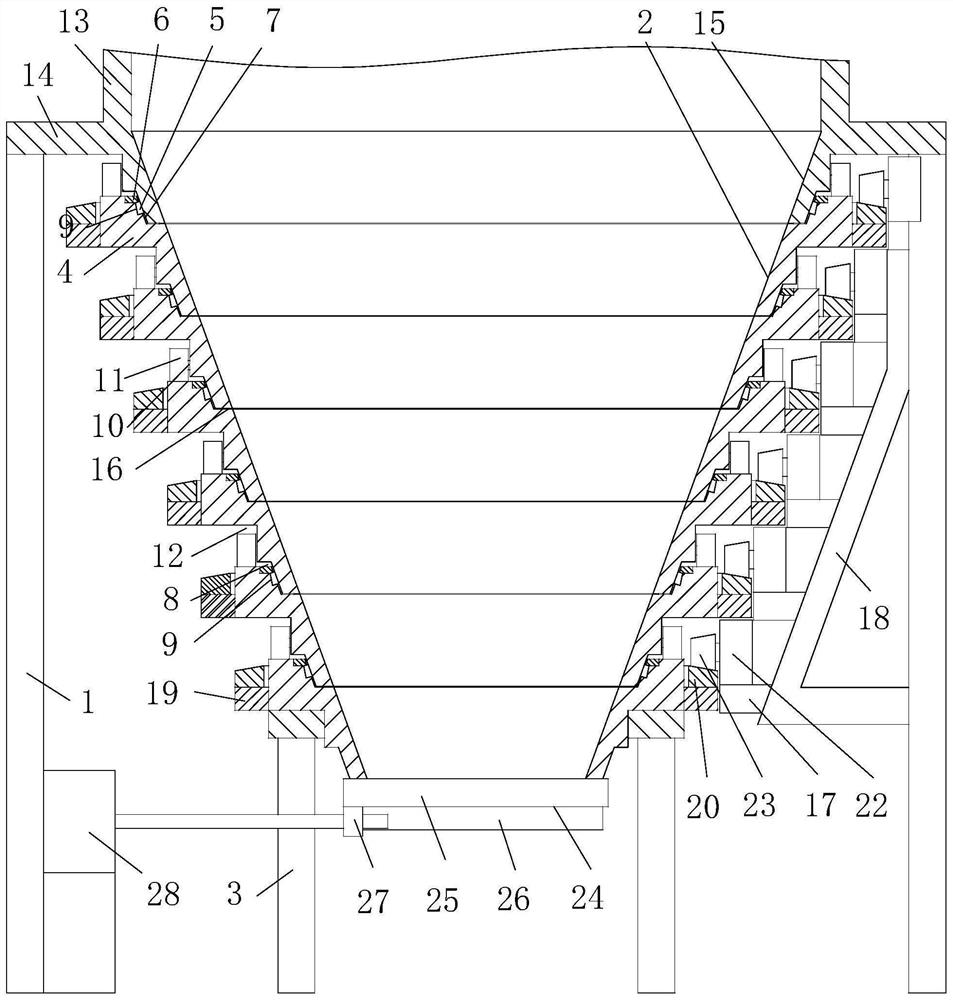

[0018] Embodiment 1, as attached figure 1 Shown: an anti-blocking material rotary bin, including: a cylindrical bin body, a conical bin body with a discharge port at the bottom of the cylindrical bin body, and a discharge gate at the lower end of the conical bin body , the support frame 1 whose upper end is screwed to the cylindrical warehouse body; the conical warehouse body includes: several rotating warehouse bodies provided with frustum-shaped inner sides 2 and pivotally connected up and down in sequence, and the lower end of the last rotating warehouse body screwed together The supporting frame 3 is the driving device for the rotating bin body; the frustum-shaped inner sides 2 of the six rotating bins form the inner side of the conical bin body; the cylindrical bin body is pivotally connected with the uppermost rotating conical bin section.

[0019] The rotating bin body includes: a rotating bin body main body 4, a plurality of tapered rollers 5, a cover ring 6; The body...

Embodiment 2

[0025] Embodiment 2, as attached figure 1 Shown: an anti-blocking material rotary bin, including: a cylindrical bin body, a conical bin body with a discharge port at the bottom of the cylindrical bin body, and a discharge gate at the lower end of the conical bin body , the support frame 1 whose upper end is screwed with the cylindrical warehouse body; the conical warehouse body includes: six rotating warehouse bodies provided with a frustum-shaped inner wall 2 and pivotally connected up and down in sequence, and screwed with the lower end of the bottom rotating warehouse body main body 4 Connected support frame 3, rotating bin body driving device; the frustum-shaped inner sides of the six rotating bins form the inner side of the conical bins; the tubular bins are pivotally connected to the last rotating conical bin section.

[0026] The rotating bin body includes: a rotating bin body main body 4, a plurality of tapered rollers 5, a cover ring 6; The body main body 4 outside i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com