Control method for preventing shelf from collapsing by goods during emergency stop and locking of Forklift AGV

A control method and shelf technology, applied in the direction of hoisting devices, lifting equipment safety devices, etc., can solve the problems of cargo dumping and no technical application, etc., and achieve the effect of improving stability and robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

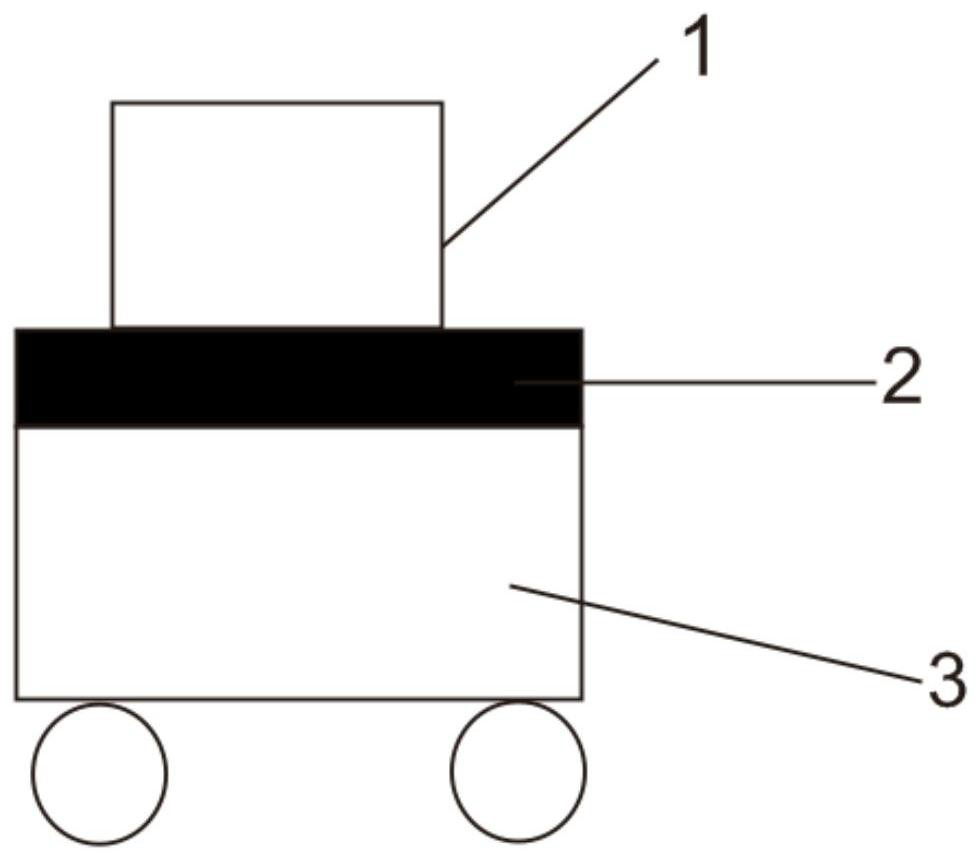

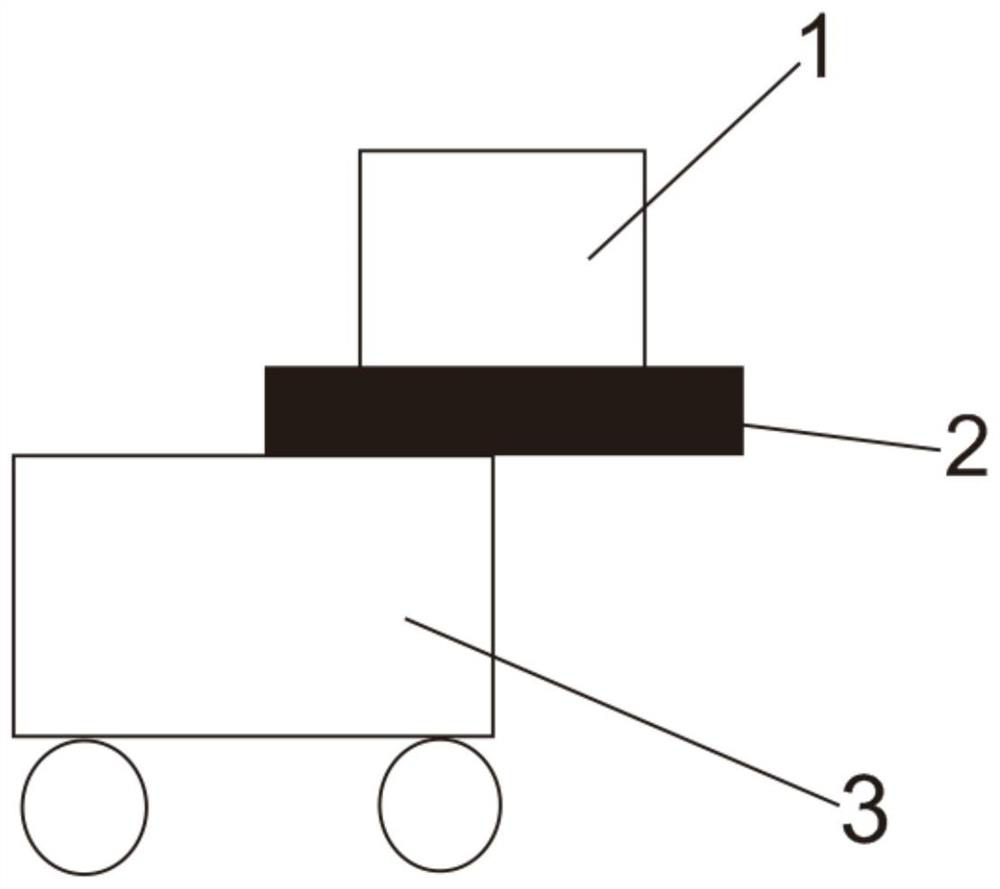

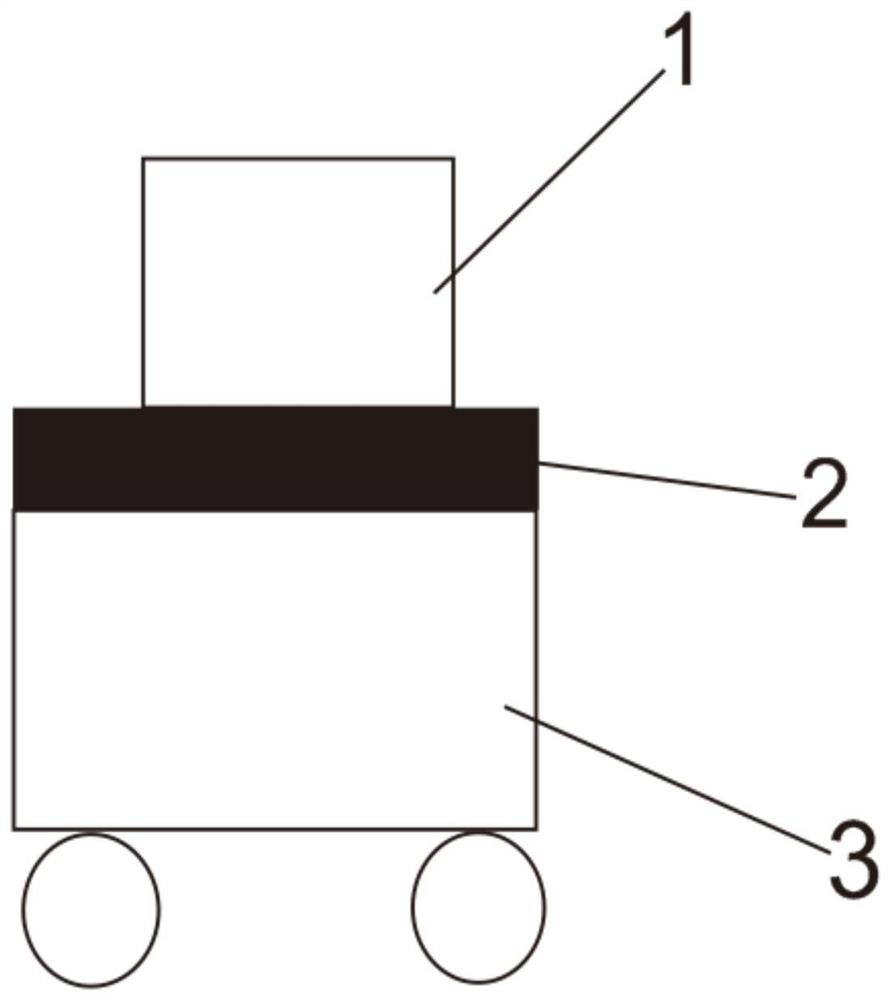

[0028] Such as Figure 1-4 In the example shown, the

[0029] A control method for preventing goods from dumping on shelves when Forklift AVG is locked in an emergency stop, comprising the following steps:

[0030] Step 1: When the Forklift AGV encounters an obstacle or failure, the main program enters an emergency stop interruption, and detects whether there is a relative speed between the goods and the shelf through the relative speed sensor on the shelf, and obtains a relative speed curve; the relative speed sensor is the displacement sensor The expression form of difference operation is as follows according to the interpolation operation formula:

[0031] f(t)=a 1 f[n 1 ]+a 2 f[n 2 ]+…+a n f[n n ]

[0032] Among them, n is the relative displacement of the goods and the shelf. The displacement interpolation at each moment can be obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com