Tractor spring testing fixture

A technology for tractors and inspection tools, which is applied to inspection tools for the symmetry of central bolts to detect the free arc height and half-chord length of tractor springs. High, time-saving and labor-saving detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

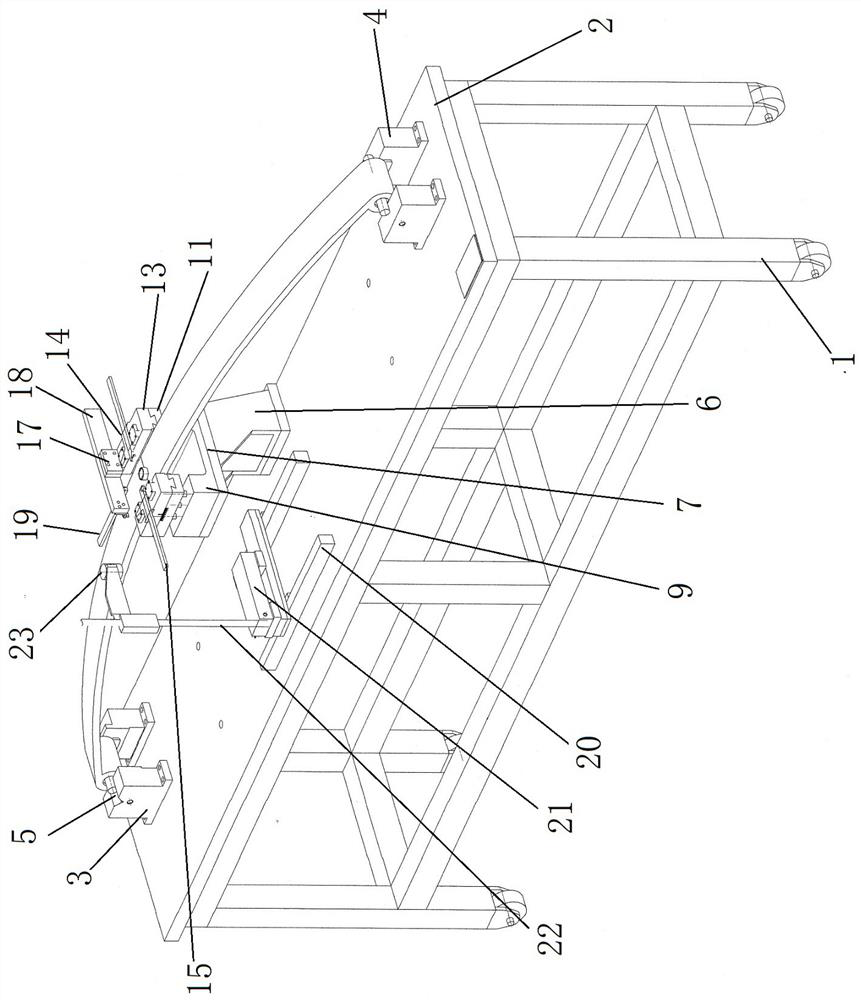

[0019] Combine below Figure 1-3 The present invention is further described;

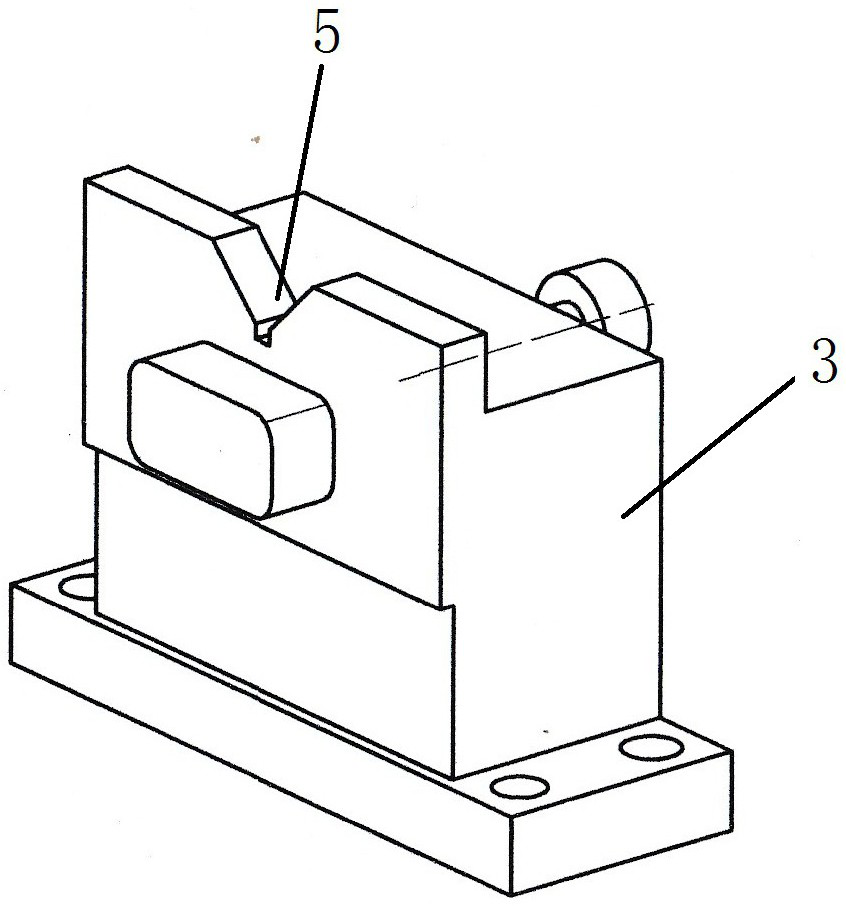

[0020] It includes a bracket 1, a base plate 2 fixed on the top of the bracket, two fixed end base blocks 3 are fixed on the upper surface of the base plate, and two movable end base blocks 4 are fixed on the right portion of the upper surface of the base plate; the two fixed end bases Both the block and the two movable end blocks are arranged one behind the other;

[0021] The upper surfaces of the two fixed-end base blocks are provided with V-shaped grooves 5 extending downward, and the two fixed-end base blocks directly below the V-shaped grooves are provided with threaded holes, and the bolts are installed in the threaded holes. The heads of the two bolts are on the outside of the two fixed-end base blocks, and the screws are exposed from the inside of the two fixed-end base blocks, that is, the screw ends of the two bolts are opposite;

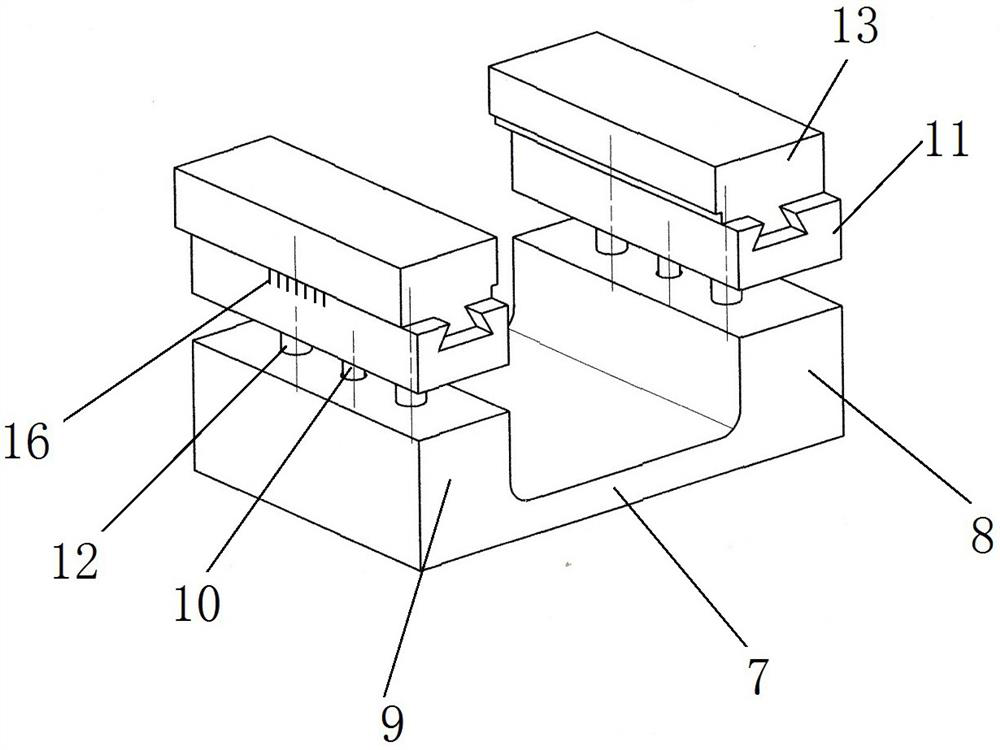

[0022] The two movable end base blocks are provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com