Detection device for electric vehicle reinforced corrosion test

A technology of corrosion test and detection device, which is used in measurement devices, vehicle testing, weather resistance/light resistance/corrosion resistance, etc., can solve the problems of low observation efficiency, mutual interference of light, and insignificant difference between light and shade in non-scratch positions. To achieve the effect of improving the difference between light and dark, easy to observe and avoid exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better understand the technical content of the present invention, specific embodiments are provided below, and the present invention is further described in conjunction with the accompanying drawings.

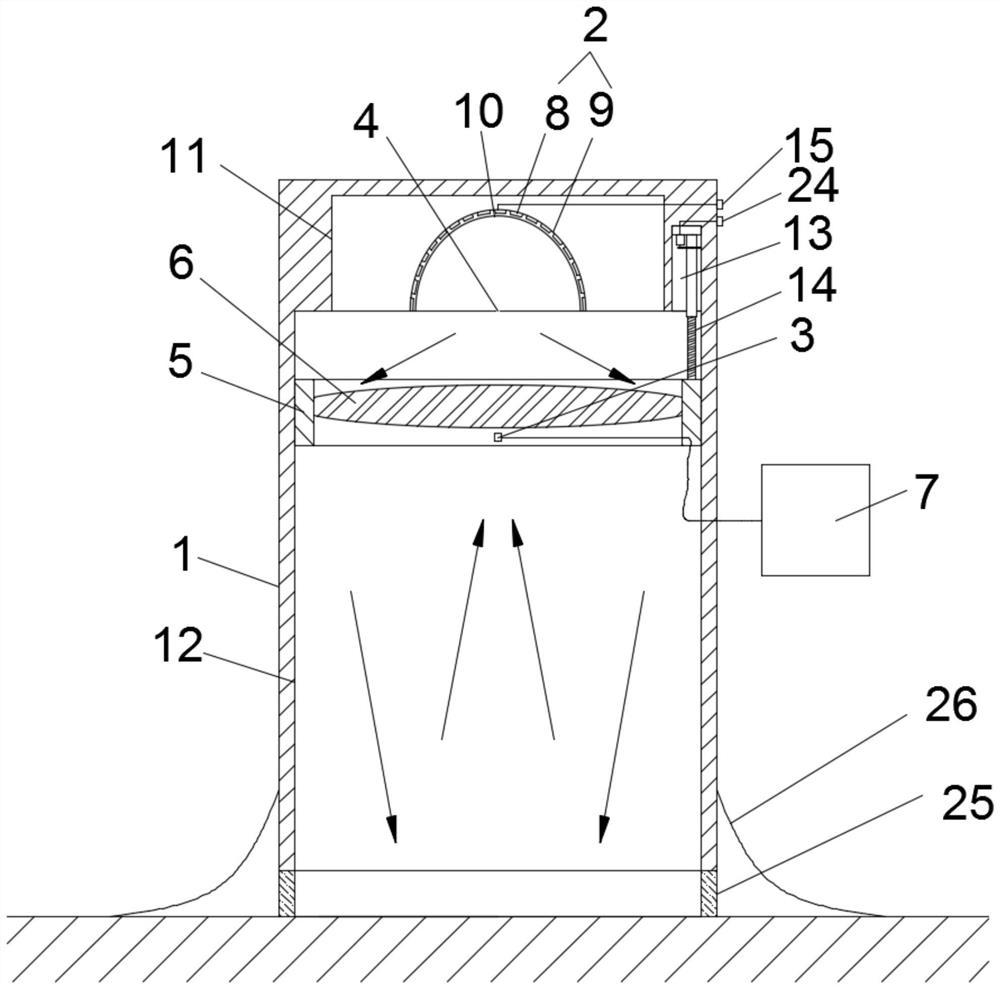

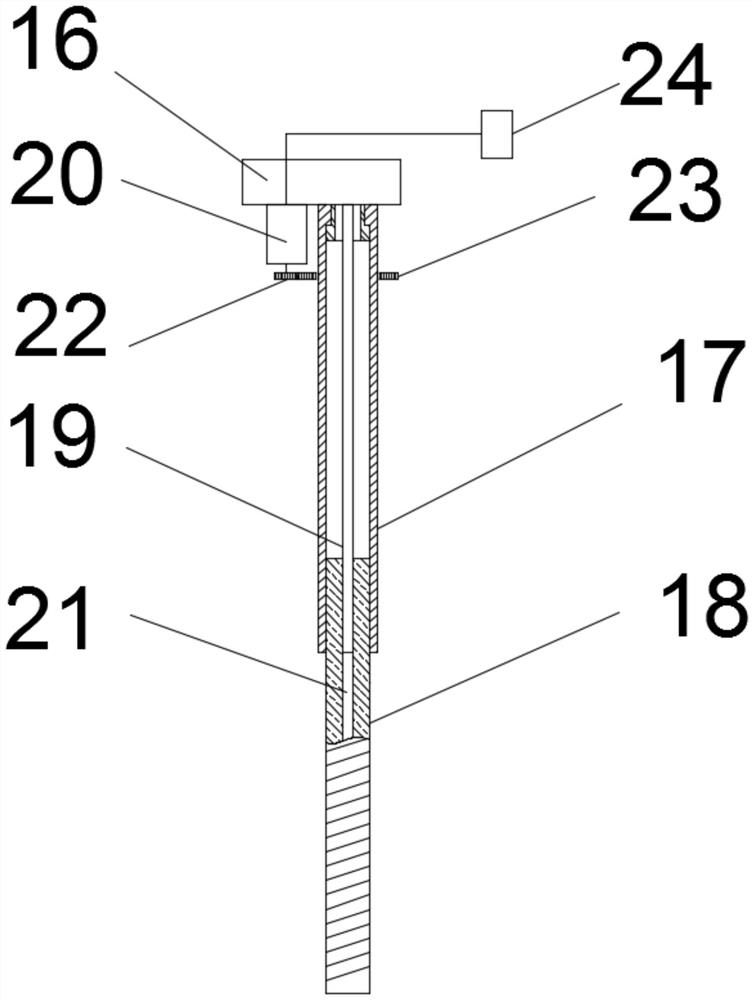

[0021] see Figure 1~2 , a detection device for an electric vehicle enhanced corrosion test, comprising a light shield 1, a light source 2 and a camera 3, the light source 2 is arranged on the top inside the light shield 1, and a light shield 27 is arranged below the light source 2 , the light-shielding plate 27 is provided with a light-through hole 4, the slide plate 5 that slides up and down along the light-shield cover 1 is arranged below the light-through hole 4, the slide plate 5 is provided with a convex lens 6, and a convex lens 6 is provided below the convex lens 6. With the camera 3, the light emitted by the light source 2 sequentially passes through the light hole 4 and the convex lens 6 and then projects onto the surface of the vehicle body. The su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com