A backlight module and display device

A backlight module, backlight technology, applied in the identification device, optics, nonlinear optics, etc., can solve the problems of product reliability and performance degradation, easy breakdown of backlight strips, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

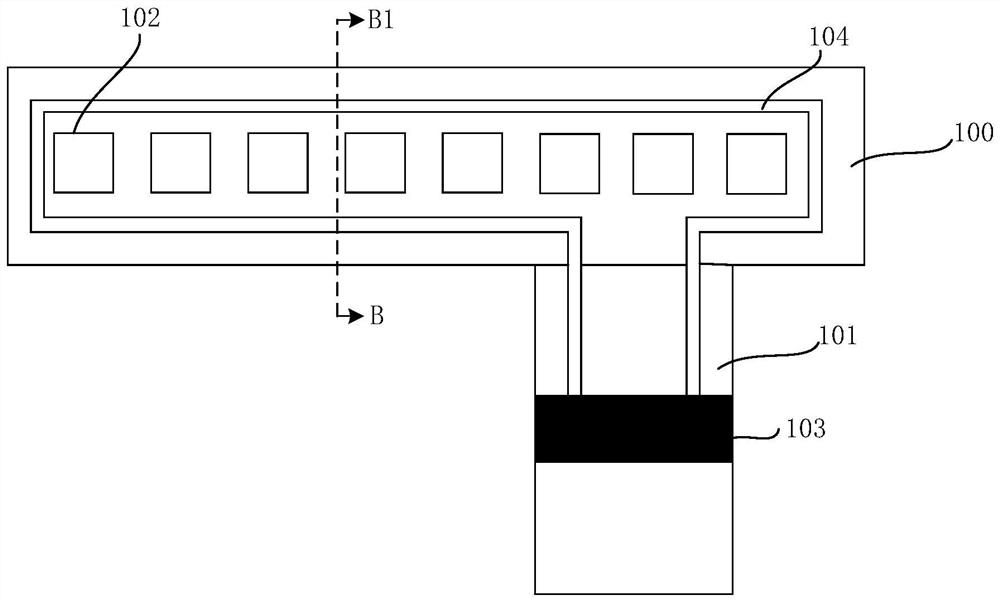

[0026] It can be known from the background art that the performance of the backlight module in the prior art needs to be improved.

[0027] A light bar is usually used as a light source in a backlight module of an existing display device, so as to provide a light source for the display panel. Light-emitting diode strips have become the preferred type of strips for display panel manufacturers because of their energy-saving and environmental protection properties. However, in the actual production process, the light-emitting diode lamp will be greatly affected by static electricity from the external environment. At the same time, in order to understand the anti-static ability of the light-emitting diode lamp, the manufacturer of the display panel usually conducts an electrostatic test on the light bar. During the process, LED lamps are usually damaged by static electricity, which leads to problems of product reliability and performance degradation.

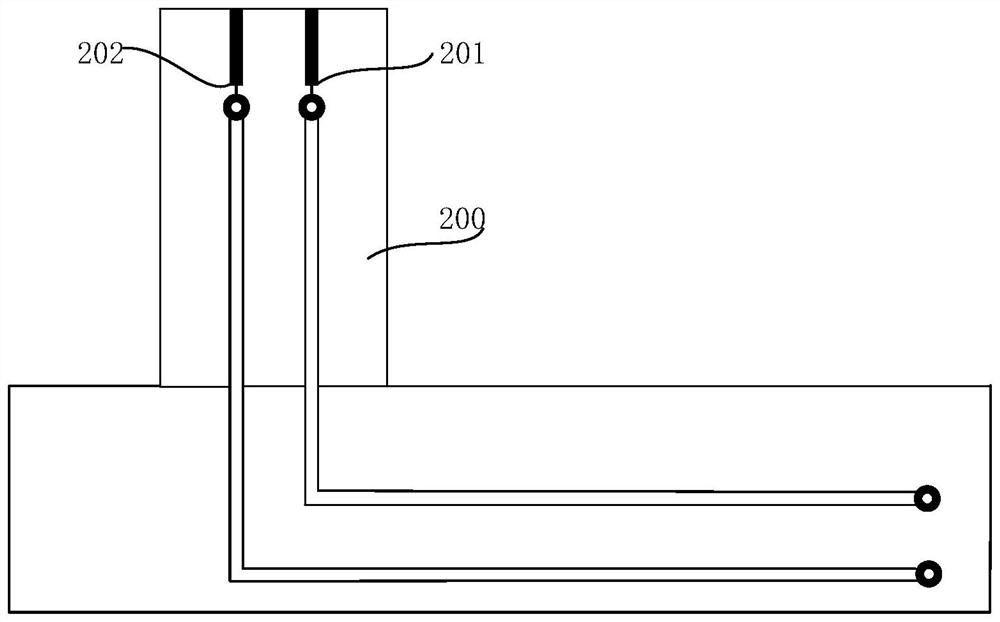

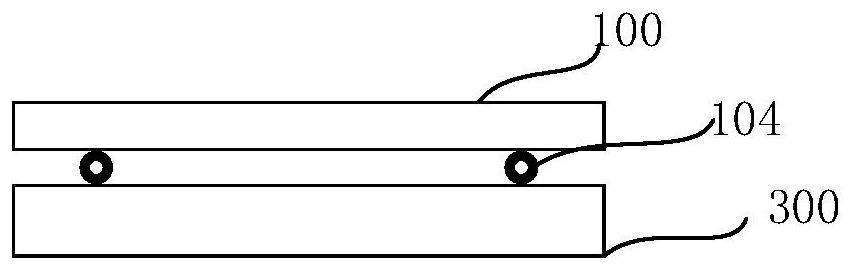

[0028] In order to solve th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com