New energy automobile battery damping fixing box

A new energy vehicle and fixing box technology, which is applied to battery pack parts, circuits, vehicle maintenance, etc., can solve the problems of unfixable battery, loose fixation, battery damage, etc., and is conducive to safe use, avoiding collisions, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

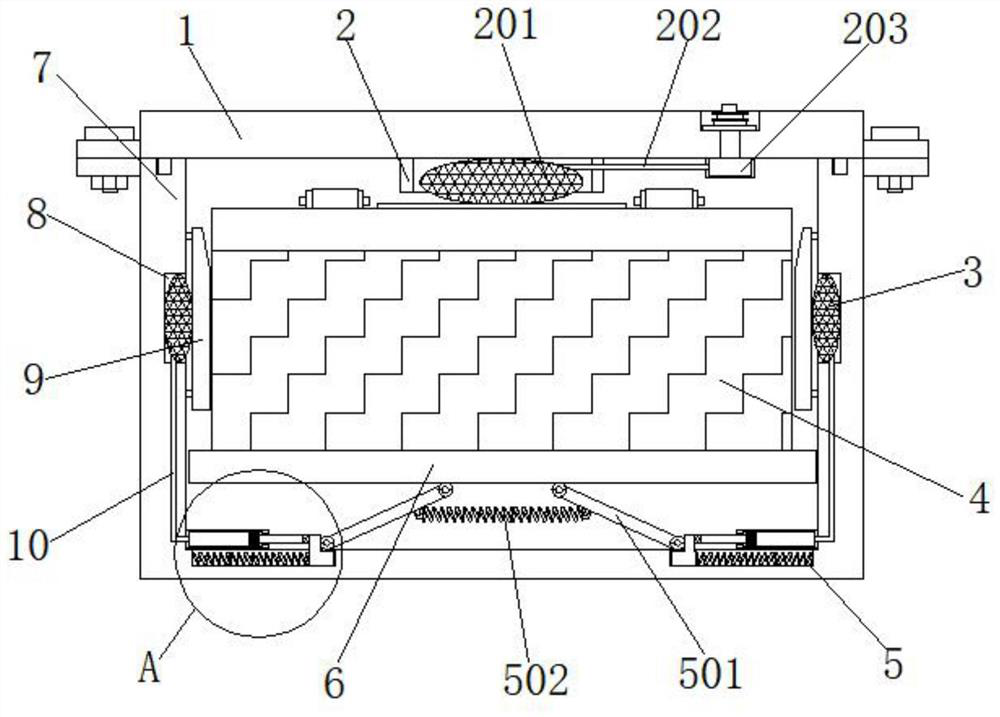

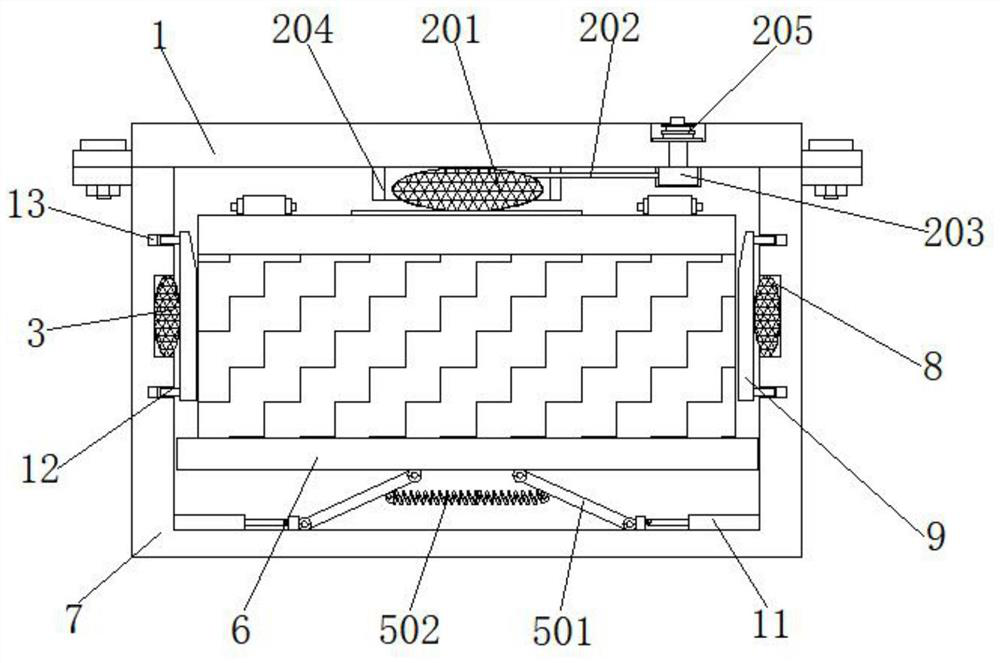

[0034] Example 1, such as Figure 1-7 As shown, when the battery 4 is installed inside the main body box 7, the battery 4 is manually put into the inside of the main body box 7, and the main body box 7 forces the movable plate 6 to descend due to gravity, so that the first connecting rod 501 and the second connecting rod 501 are connected to each other. The angle between the rod 142 and the bottom of the movable plate 6 becomes smaller gradually, the fourth spring 143 and the first spring 502 are stressed and stretched and store elastic potential energy, and the bottom end of the first connecting rod 501 pushes the first slide block 503 in the first slide. The inside of the groove 505 slides, the third spring 504 shortens and stores elastic potential energy, and the first connecting rod 501 pushes the cylinder 11 to shorten, forcing the pressure inside the cylinder 11 to increase, thereby forcing the second air bag 3 to expand a little more, thereby pushing the splint 9 Close ...

Embodiment 2

[0035] Example 2, such as figure 1 , 2 , 3, 4, 6 and 7, when the main body box 7 was stressed and bumped down, the angle between the second connecting rod 142 and the first connecting rod 501 and the bottom of the movable plate 6 continued to decrease, and the fourth spring 143 and the first A spring 502 is stressed and continues to stretch and store elastic potential energy. The bottom end of the first connecting rod 501 continues to push the first slider 503 to slide inside the first slide groove 505. The third spring 504 continues to shorten and store elastic potential energy. A connecting rod 501 pushes the cylinder 11 to shorten again, forcing the pressure inside the cylinder 11 to increase again, thereby forcing the second airbag 3 to expand even more, thereby pushing the splint 9 and the outside of the battery 4 to stick closer together, improving the device's resistance to the battery. The stability that storage battery 4 is fixed.

Embodiment 3

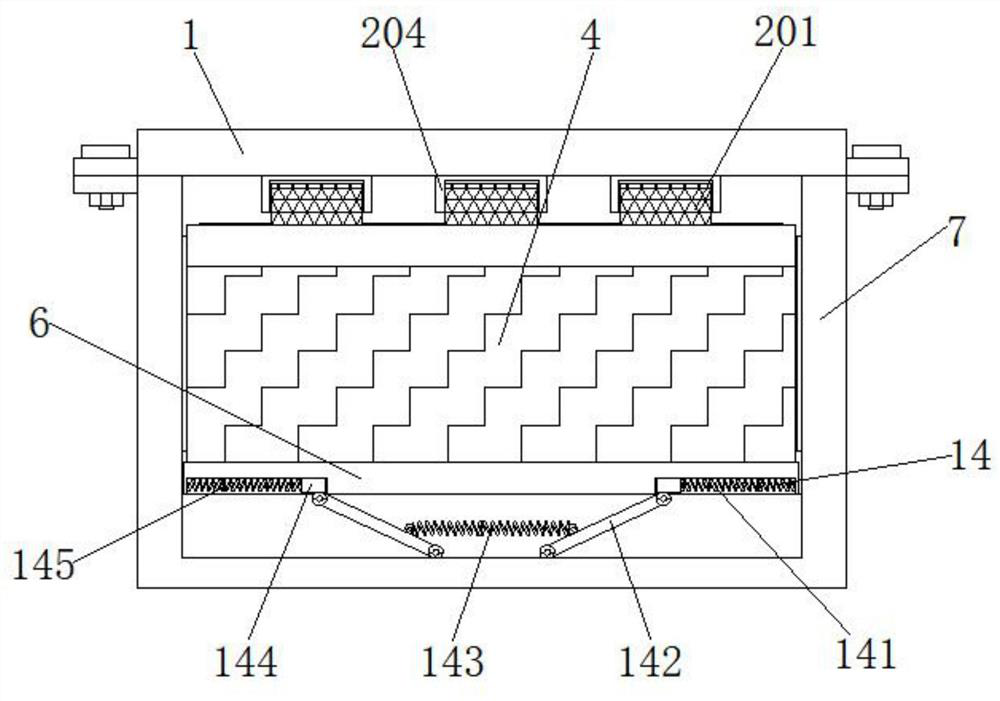

[0036] Example 3, such as Figure 1-7 As shown, when the main body box 7 is bumped up under force, the fourth spring 143, the first spring 502, the second spring 145 and the third spring 504 release the stored elastic potential energy, and the force generated by the elastic potential energy forces the movable plate 6 to drive the storage battery 4 rise together inside the main body box 7, and because the interior of multiple sets of first airbags 201 is filled with air, the first airbags 201 are deformed under force and buffer the received force.

[0037] Working principle: When it is necessary to install the battery 4 into the main body box 7, manually put the battery 4 into the main body box 7, and the main body box 7 will force the movable plate 6 to descend due to gravity, so that the first connecting rod 501 and the second connecting rod 501 The angle between the two connecting rods 142 and the bottom of the movable plate 6 becomes smaller gradually, the fourth spring 143...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com