Heat dissipation device applied to numerical control laser cutting

A technology of heat dissipation device and numerical control laser, applied in numerical control field, can solve the problem of poor heat dissipation effect, etc., and achieve the effect of improving heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

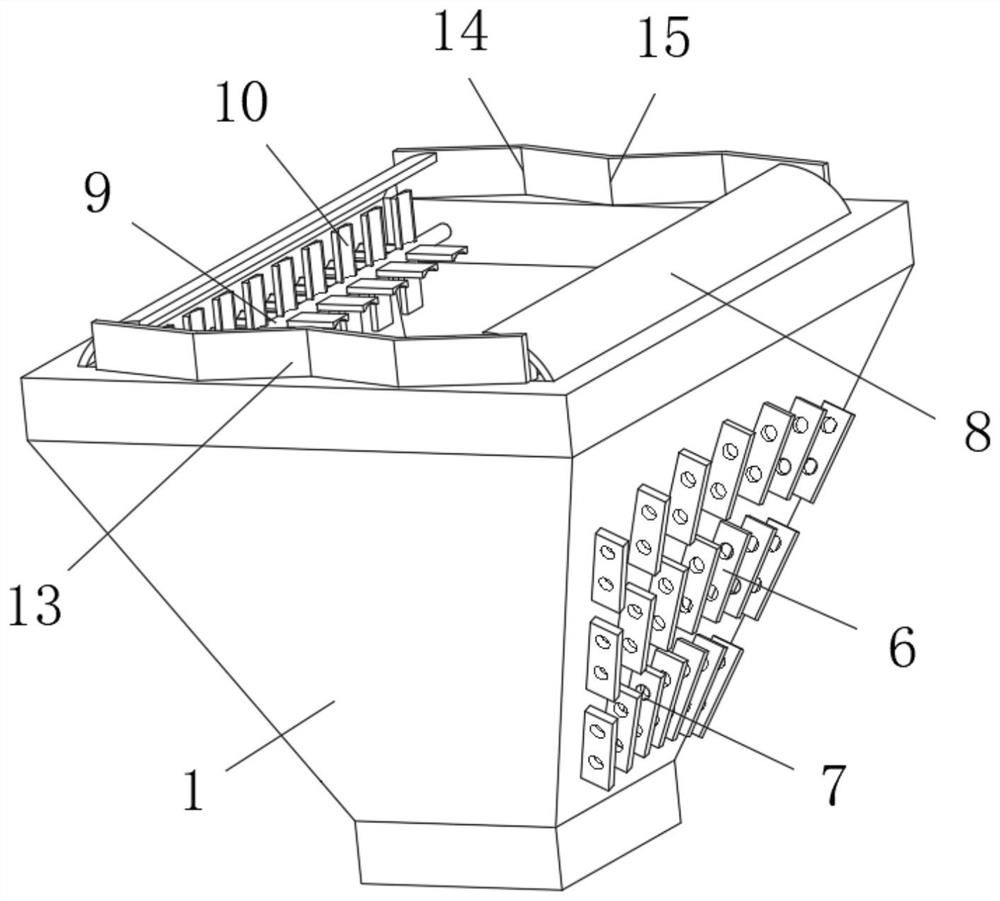

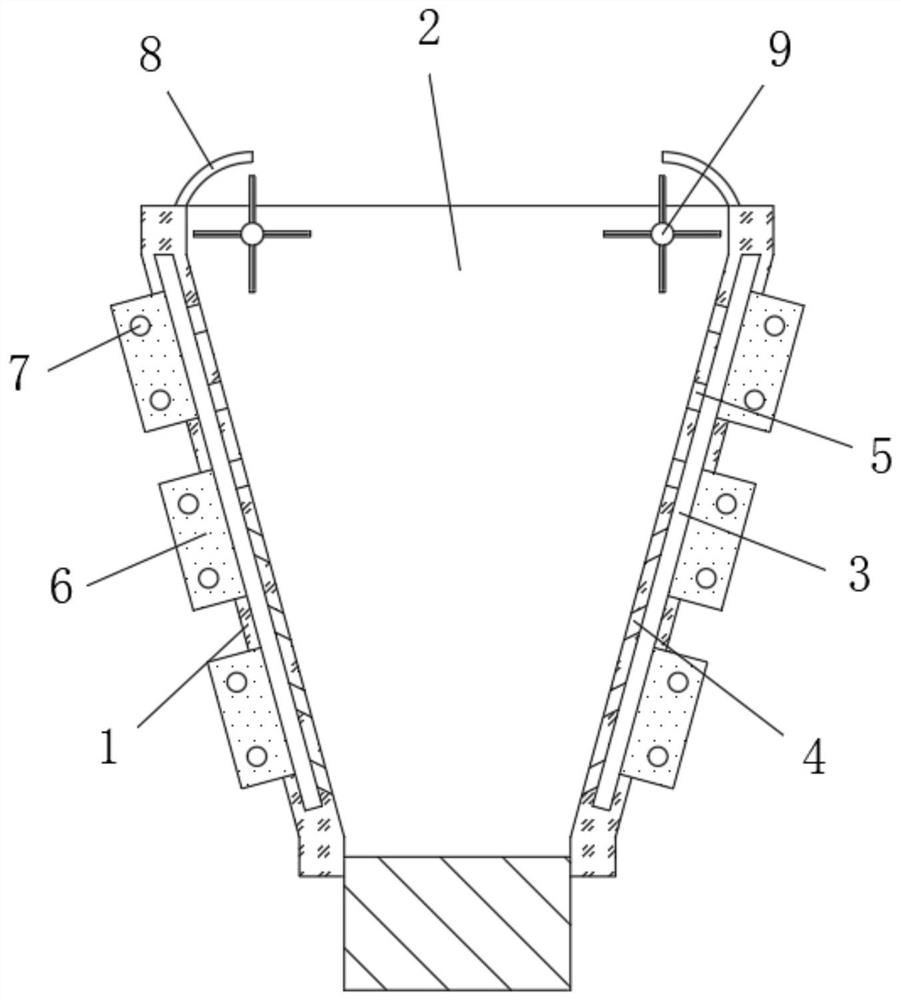

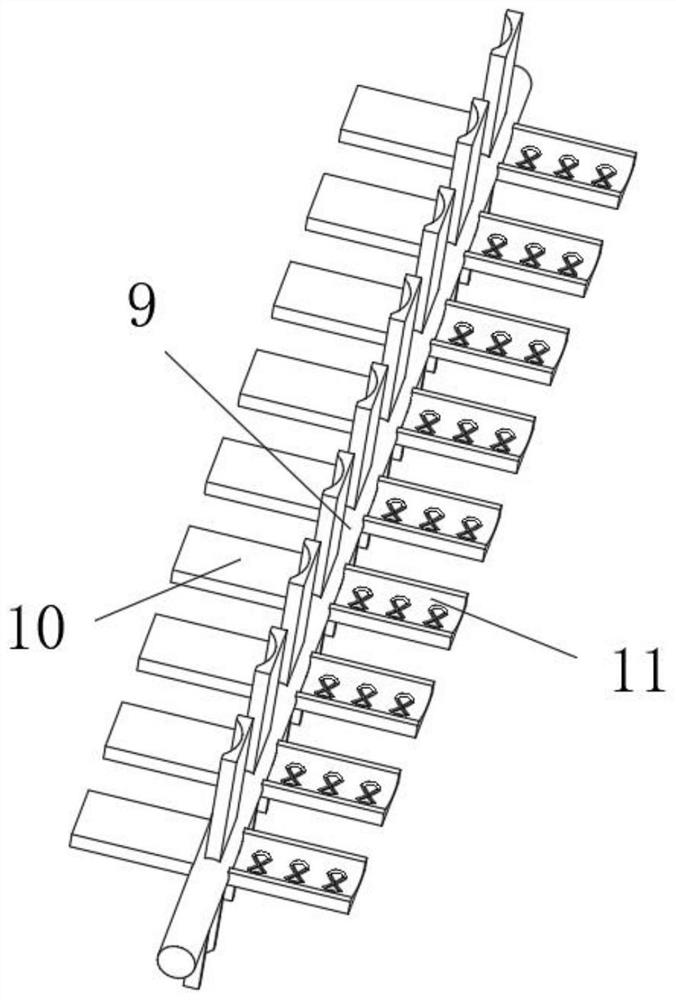

[0027] refer to Figure 1-4 , a heat dissipation device applied to CNC laser cutting, including a hopper 1, a collection chamber 2 is arranged inside the hopper 1, and the cross-sectional area of the collection chamber 2 decreases gradually as the height decreases, and the bottom end of the collection chamber 2 is connected with The exhaust pipe, the two ends of the hopper 1 and the inner walls on both sides are all set as inclined surfaces, and the inside of the shell on both sides of the hopper 1 is provided with a connecting cavity 3, and the connecting cavity 3 is provided with an inclined shape that matches the inner wall of the collecting cavity 2. The top of the inner wall of the connection chamber 3 close to the collection chamber 2 is provided with a plurality of ventilation holes 5, and the bottom of the inner wall of the connection chamber 3 near the collection chamber 2 is provided with a plurality of ventilation holes 4, and the connection chamber 3 is far away f...

Embodiment 2

[0035] refer to Figure 1-5, a heat dissipation device applied to CNC laser cutting, the inner walls of both ends of the hopper 1 are provided with auxiliary grooves 16 distributed equidistantly in the vertical direction, and the auxiliary grooves 16 are arranged in a V-shaped structure, and the middle position of the auxiliary grooves 16 Protruding upward, a diffuser groove 17 with an arc-shaped structure is opened in the middle of the bottom inner wall of the auxiliary groove 16 .

[0036] When in use, the middle position of the auxiliary groove 16 protrudes upwards, so that the hot air entering the auxiliary groove 16 on both sides is led to the middle position and dispersed through the diffusion groove 17 to reduce the upward impact force, and the hot air entering the auxiliary groove 16 at the middle position will flow along the The auxiliary groove 16 drains water to the bottom of both sides, so as to further enhance the actual heat dissipation effect of the device on CN...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com