Textile roller support for fixing textile roller based on textile production

A textile roller and stationary phase technology, applied in tool storage devices, manufacturing tools, etc., can solve problems such as textile roller shedding, and achieve the effect of ensuring directivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

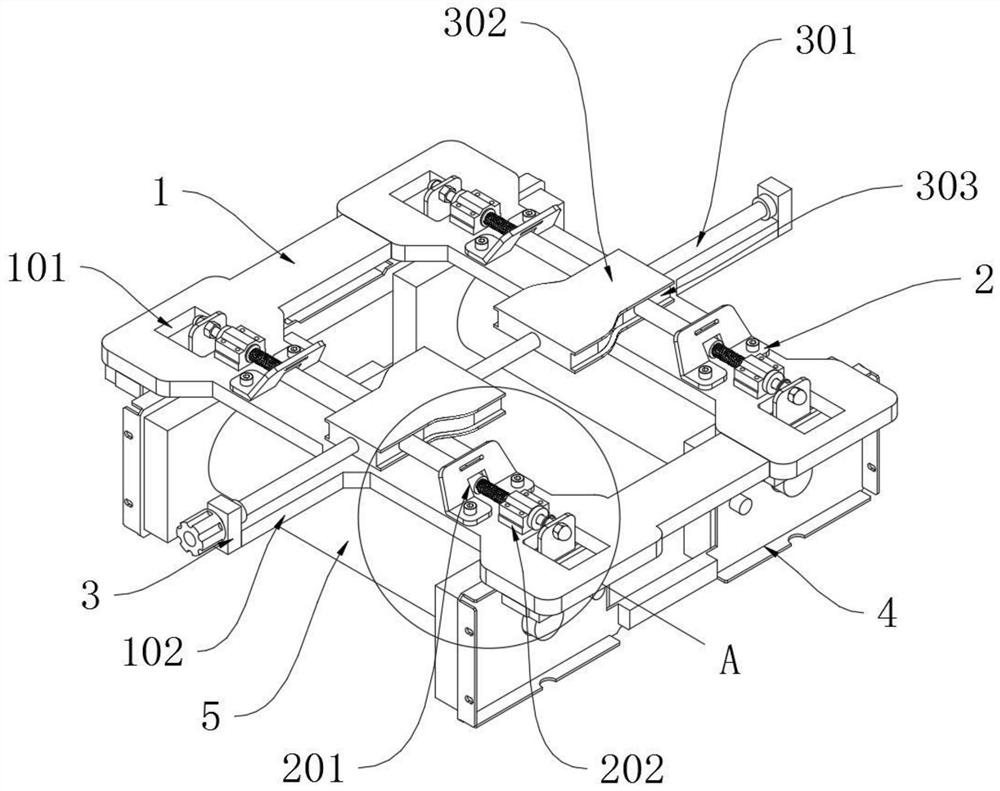

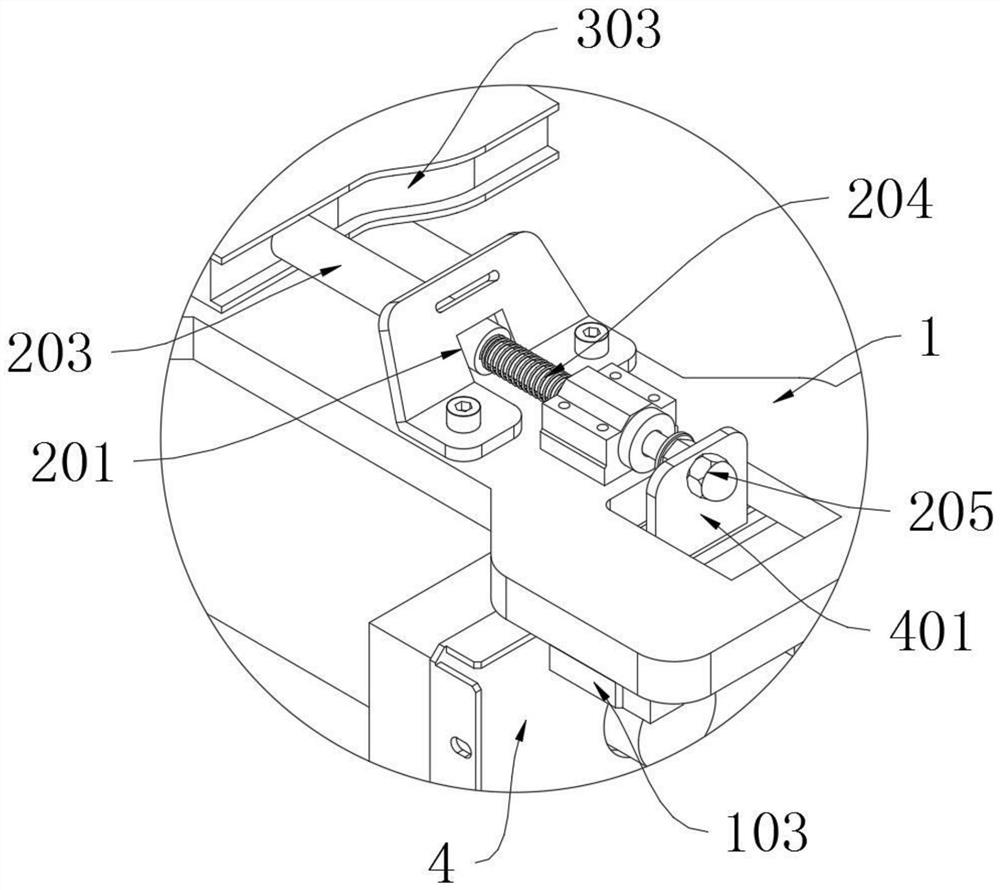

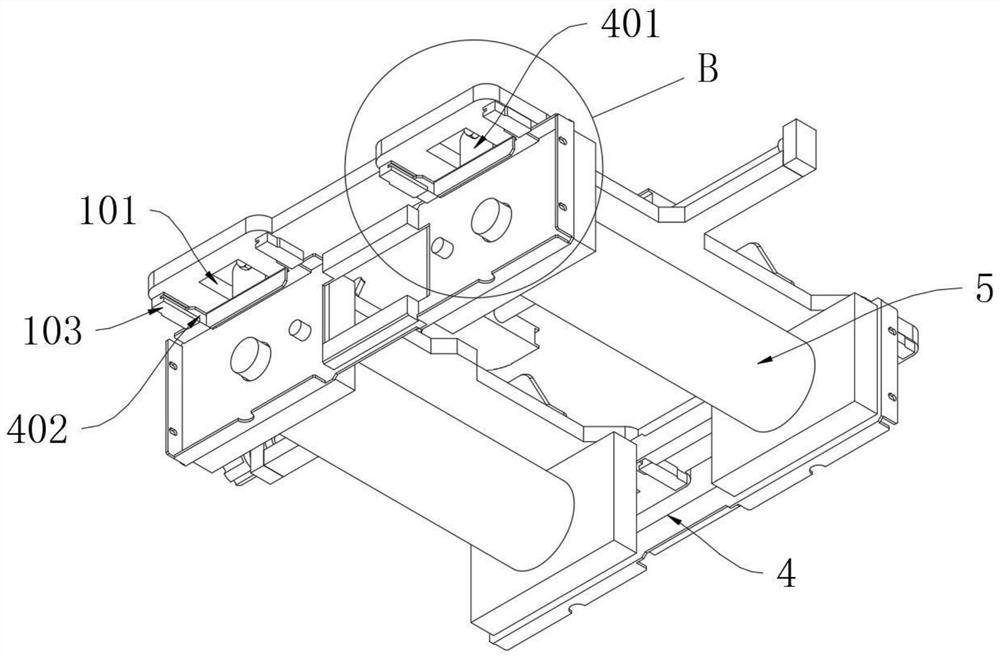

[0034] as attached figure 1 to attach Figure 8 Shown:

[0035]The present invention provides a textile roll support for fixing textile rolls based on textile production, which includes a support body 1; the four corners of the top plane of the support body 1 are respectively fixed with mutually symmetrical guide mechanisms 2; the support body 1 includes self-adaptive adjustment holes 101 and wing platform 102, the four corners of the bracket main body 1 are respectively provided with rectangular self-adaptive adjustment holes 101 that penetrate up and down, and the upper part structure of the roller plate 4 passes through the self-adaptive adjustment holes 101, the top plane of the bracket main body 1 Between the middle part of the front end and the middle part of the rear end, an outwardly extending wing platform 102 is longitudinally fixedly installed, while the adjustment mechanism 3 is fixedly installed with two front and rear wing platforms 102; The roller plate 4, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com