Material ejecting device facilitating metal mold processing

A metal mold and elastic material technology, which is applied in the field of elastic material device, can solve the problems of ejection of molds that cannot be formed, transportation of molds that cannot be formed, etc., and achieve the effects of improving production efficiency, improving work efficiency, and increasing the speed of retrieving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

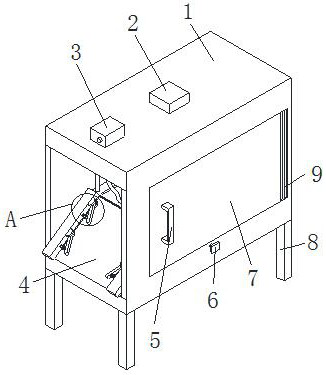

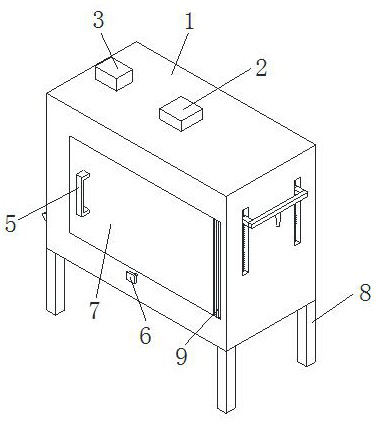

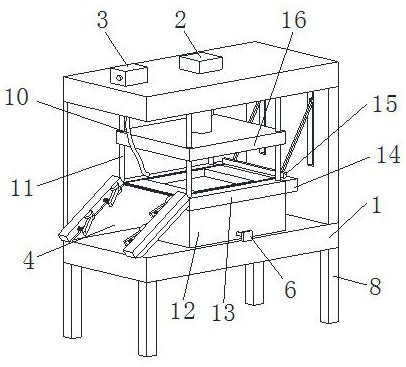

[0030] see Figure 1-8 , the present invention provides the following technical solutions: a kind of spring material device for metal mold processing, comprising a box body 1, the top of the box body 1 is fixedly connected with a refrigeration box 3, the top of the box body 1 is fixedly connected with a hydraulic cylinder 2, the box body The inner bottom wall of 1 is fixedly connected with a working box 12, the top of the working box 12 is fixedly connected with a lower mold 13, the top four corners of the lower mold 13 are fixedly connected with a sliding rod 11, and the outer surface of the sliding rod 11 is slidingly connected with an upper mold 16 , the top of the upper mold 16 is fixedly connected to the bottom of the hydraulic cylinder 2, the bottom of the refrigeration box 3 is communicated with and fixed with an outlet pipe 10, the top of the lower mold 13 is movably connected to a mold plate 19, and the bottom of the mold plate 19 is fixedly connected to a movable Blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com