Straw wetting and softening equipment for straw tableware production

A straw and moistening technology, which is applied in the field of straw moistening and softening equipment, can solve the problems of poor moistening and softening effect and long time consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

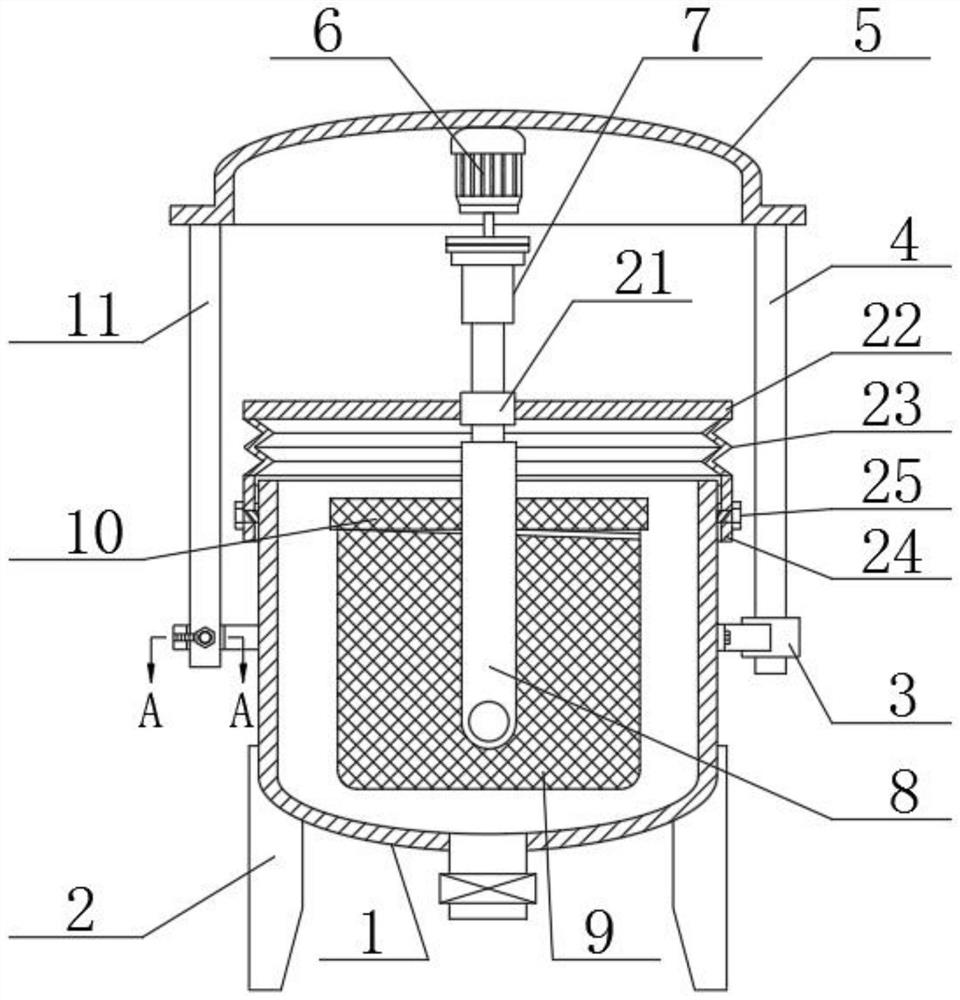

[0030] Such as Figure 1-2 As shown, a straw moistening and softening equipment for the production of straw tableware includes a tank body 1, the lower end of the tank body 1 is connected with a feeding pipe, and a control valve is arranged on the feeding pipe.

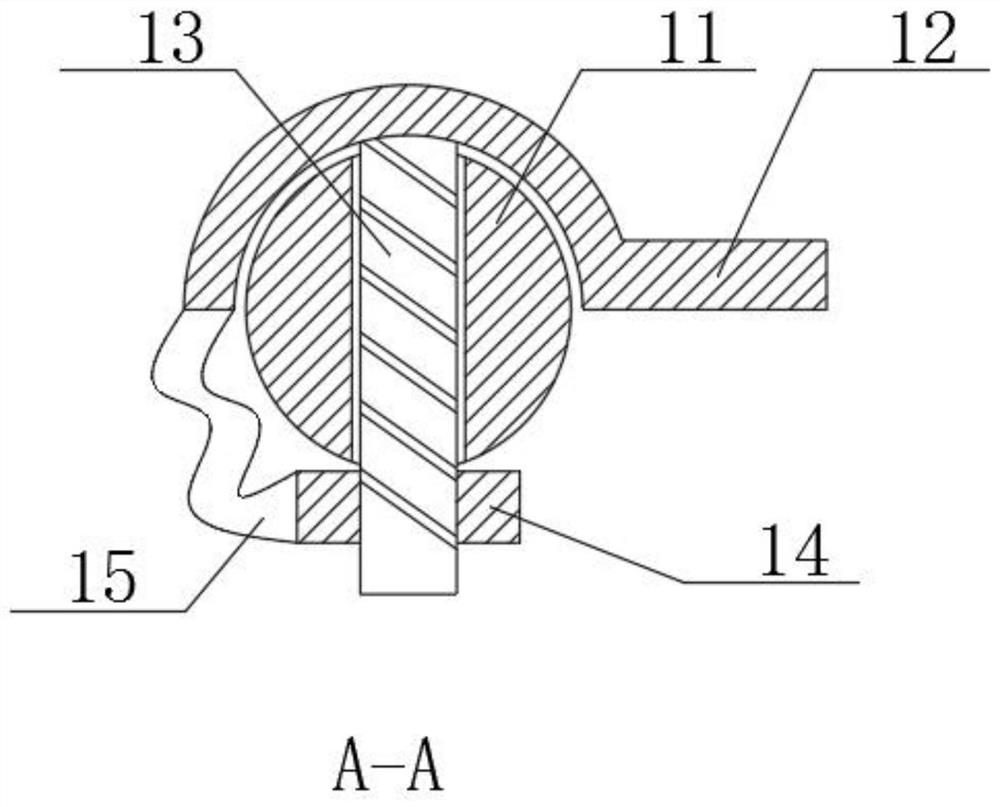

[0031] The lower end of the tank body 1 is connected with three support legs 2 equidistant in circular distribution, the outer wall of the tank body 1 is connected with a bearing 3, a rotating shaft 4 is fixedly inserted in the bearing 3, and an upper cover 5 is connected to the upper end of the rotating shaft 4, The upper cover 5 is connected with a long rod 11, and the long rod 11 is connected with the outer wall of the tank body 1 through a fixing mechanism,

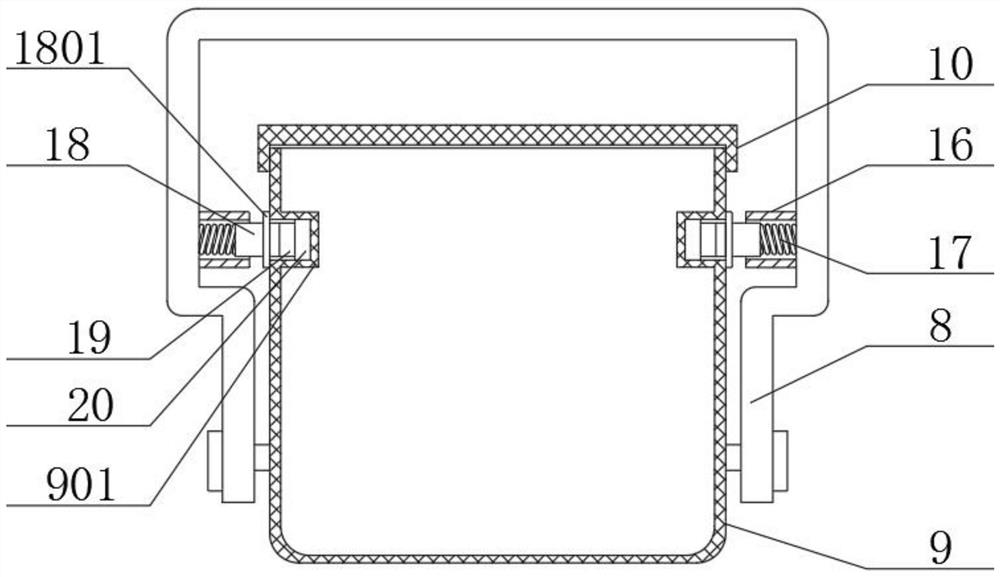

[0032] The inner top wall of the upper cover 5 is connected with a drive motor 6, and the output end of the drive motor 6 is connected with a U-shaped rod 8 through an electric push rod 7, and the side walls of the two vertical sections of the U-shaped rod 8 ...

Embodiment 2

[0040] Such as Figure 1-3 As shown, a straw moistening and softening equipment for the production of straw tableware includes a tank body 1, the lower end of the tank body 1 is connected with a feeding pipe, and a control valve is arranged on the feeding pipe.

[0041] The lower end of the tank body 1 is connected with three support legs 2 equidistant in circular distribution, the outer wall of the tank body 1 is connected with a bearing 3, a rotating shaft 4 is fixedly inserted in the bearing 3, and an upper cover 5 is connected to the upper end of the rotating shaft 4, The upper cover 5 is connected with a long rod 11, and the long rod 11 is connected with the outer wall of the tank body 1 through a fixing mechanism,

[0042] The inner top wall of the upper cover 5 is connected with a drive motor 6, and the output end of the drive motor 6 is connected with a U-shaped rod 8 through an electric push rod 7, and the side walls of the two vertical sections of the U-shaped rod 8 ...

Embodiment 3

[0050] Such as Figure 1-2 As shown, a straw moistening and softening equipment for the production of straw tableware includes a tank body 1, the lower end of the tank body 1 is connected with a feeding pipe, and a control valve is arranged on the feeding pipe.

[0051] The lower end of the tank body 1 is connected with three support legs 2 equidistant in circular distribution, the outer wall of the tank body 1 is connected with a bearing 3, a rotating shaft 4 is fixedly inserted in the bearing 3, and an upper cover 5 is connected to the upper end of the rotating shaft 4, The upper cover 5 is connected with a long rod 11, and the long rod 11 is connected with the outer wall of the tank body 1 through a fixing mechanism,

[0052] The inner top wall of the upper cover 5 is connected with a drive motor 6, and the output end of the drive motor 6 is connected with a U-shaped rod 8 through an electric push rod 7, and the side walls of the two vertical sections of the U-shaped rod 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com