Flexible pressing mechanism for glass forming

A glass forming and flexible mechanism technology, applied in glass forming, glass remolding, glass manufacturing equipment, etc., can solve the problems of the rollers being vertical, the rollers cannot contact the glass, and the deformation is large, so as to prevent warping. rebound effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the drawings and embodiments, but it is not used as a basis for any limitation on the invention.

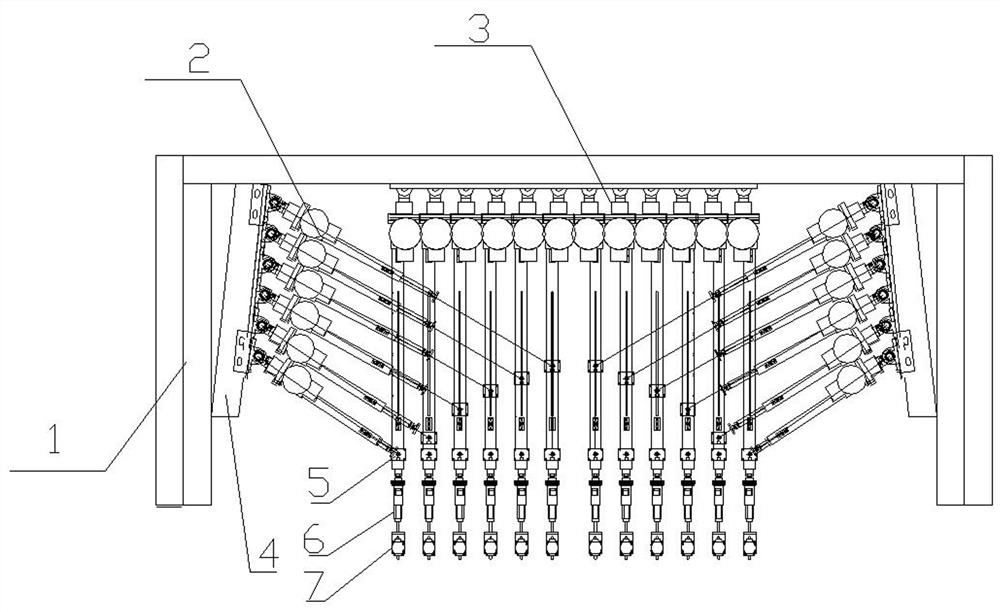

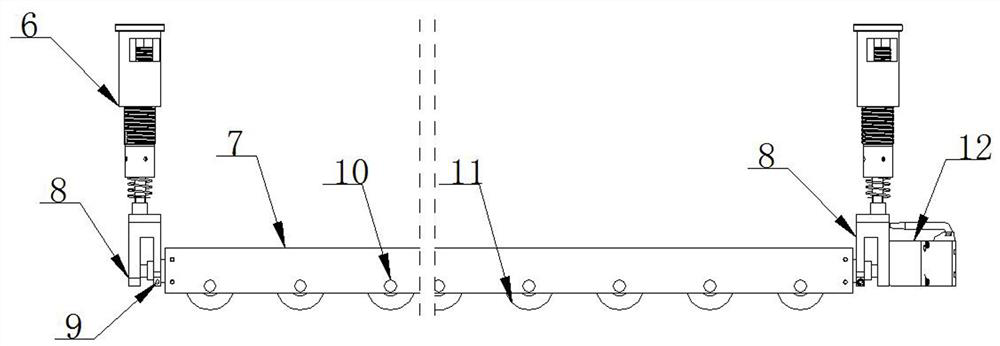

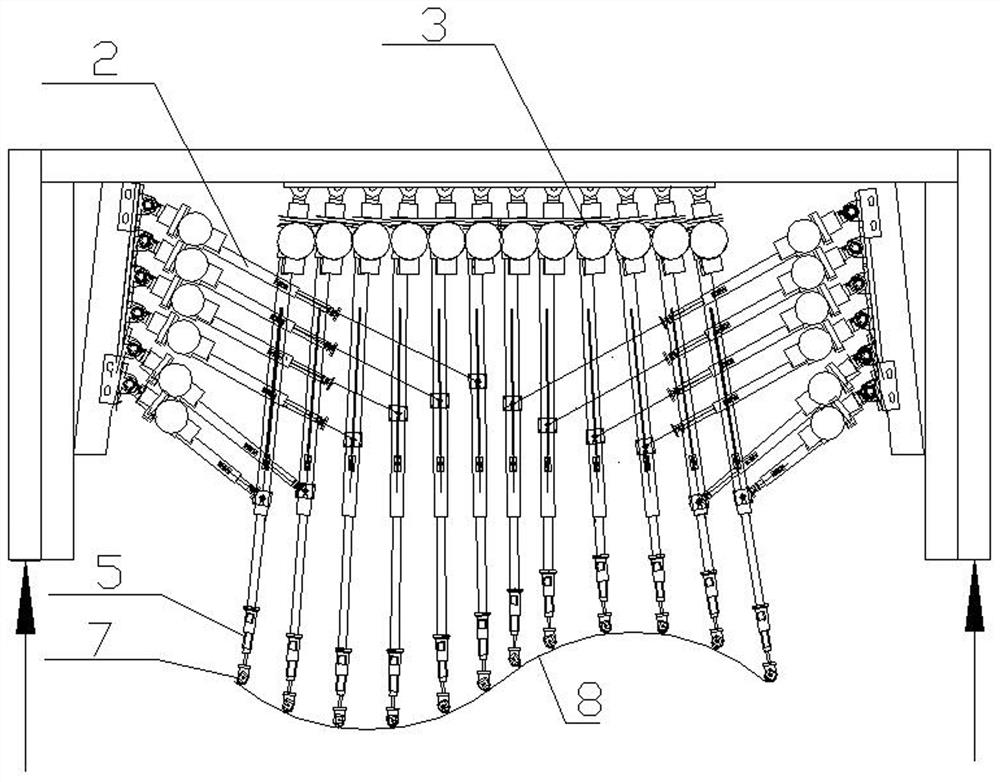

[0022] Referring to the accompanying drawings, a flexible down-pressing mechanism for glass molding includes a frame 1 and a plurality of down-pressing beams 7, the frame 1 is set above the forming frame of the glass forming equipment through a lifting cylinder, and the lifting cylinder can To control the lifting of the frame 1, the plurality of down-pressing beams 7 are arranged at intervals perpendicular to the glass conveying direction, and at the lower part of the down-pressing beams 7, a plurality of freely rotatable rollers 11 are arranged at intervals along its length direction, and the rollers 11 The pin shaft 10 is installed on the pressing beam 7, and the roller 11 can adopt a polytetrafluoroethylene wheel, or an aluminum wheel or the like that can directly contact the glass surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com