Self-tightening-and-loosening sleeper fastener bolt operation vehicle and operation method thereof

A technology of sleeper fasteners and work vehicles, which is applied in the direction of track, track laying, track maintenance, etc. It can solve the problems of low positioning accuracy, fixed lateral distance, and inability to adapt to large changes in bolt spacing, so as to achieve stable operation of the trolley and realize Different heights to achieve the effect of precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

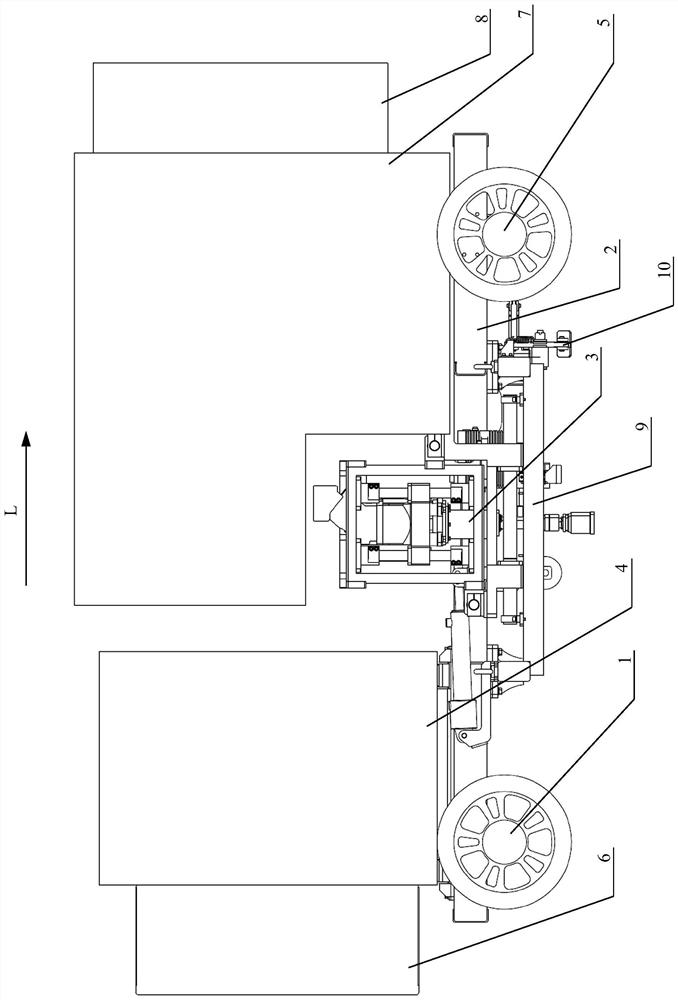

[0072] as attached figure 1 to attach Figure 12 As shown, an embodiment of the self-tightening sleeper fastener bolt operation vehicle of the present invention, the operation vehicle 100 specifically includes:

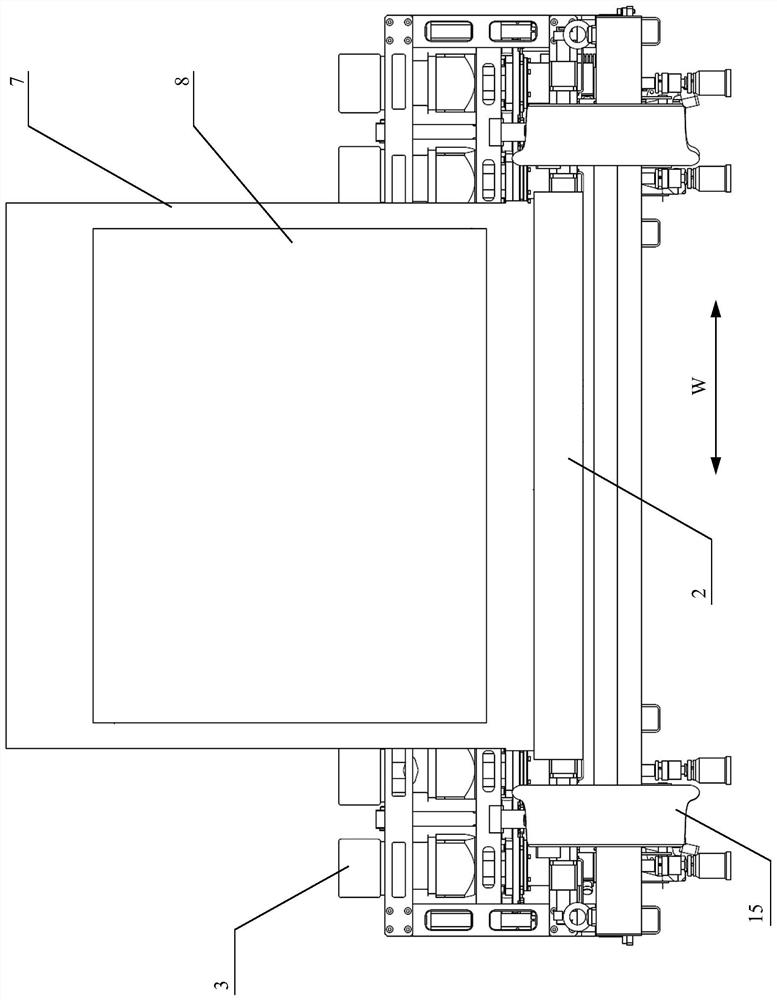

[0073]The vehicle frame 2 supported on the rail 11 by the wheel set 15;

[0074] A subframe 9 arranged laterally on the vehicle frame 2; the subframe 9 can be further specifically installed below the vehicle frame 2;

[0075] The operating mechanism 3 is arranged on at least one of the left and right sides of the sub-frame 9 and is located outside the vehicle frame 2 along the transverse direction.

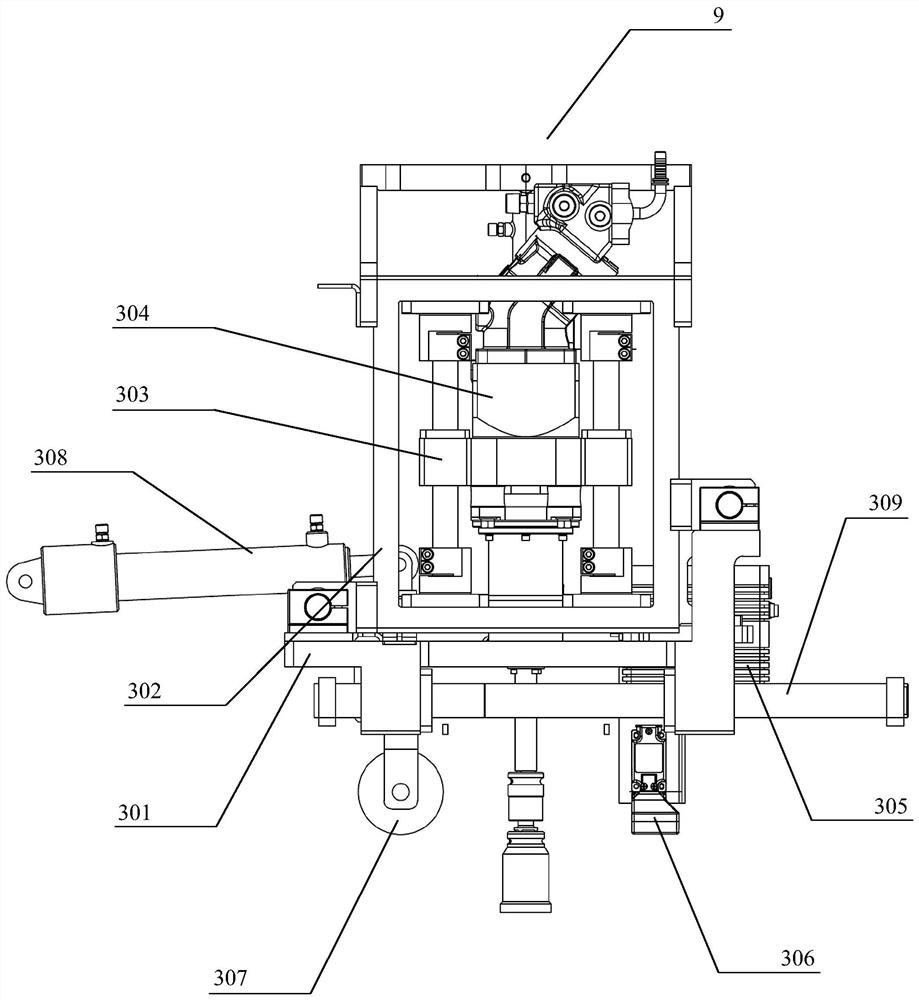

[0076] The operating mechanism 3 is provided with a sensor assembly 306 for detecting the bolt 13 , an image acquisition assembly 305 for positioning the bolt 13 , and an elastic shaft device 304 for tightening or loosening the bolt 13 . The working mechanism 3 can drive the elastic shaft device 304 to move laterally, longitudinally and vertically relative to the sub-f...

Embodiment 2

[0089] A kind of embodiment as described in embodiment 1 self-tightening sleeper fastener bolt operation method embodiment, this method specifically comprises the following steps:

[0090] S10) When the work vehicle 100 is running, the sensor assembly 306 detects the bolt 13 at the same time;

[0091] S20) When the sensor assembly 306 detects the bolt 13, the work vehicle 100 brakes and stops walking, and simultaneously clamps the rail 11 through the rail clamping device 10;

[0092] S30) The image acquisition component 305 starts taking pictures and acquires the position of the bolt 13, and the longitudinal drive mechanism 308 drives the elastic shaft device 304 to move a corresponding distance;

[0093] S40) When the elastic shaft device 304 reaches the designated position, the vertical driving mechanism 310 presses down for a set distance so that the sleeve 30407 is placed on the bolt 13;

[0094] S50) The drive unit 30401 of the elastic shaft device 304 starts to rotate, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com