Steel part butt-joint machine for building steel structure assembly type building framework

A prefabricated, steel structure technology, applied in construction, building structure, construction material processing, etc., can solve the problems of high precision, failure to use normally, high cost, etc., and achieve the effect of improving the clamping structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

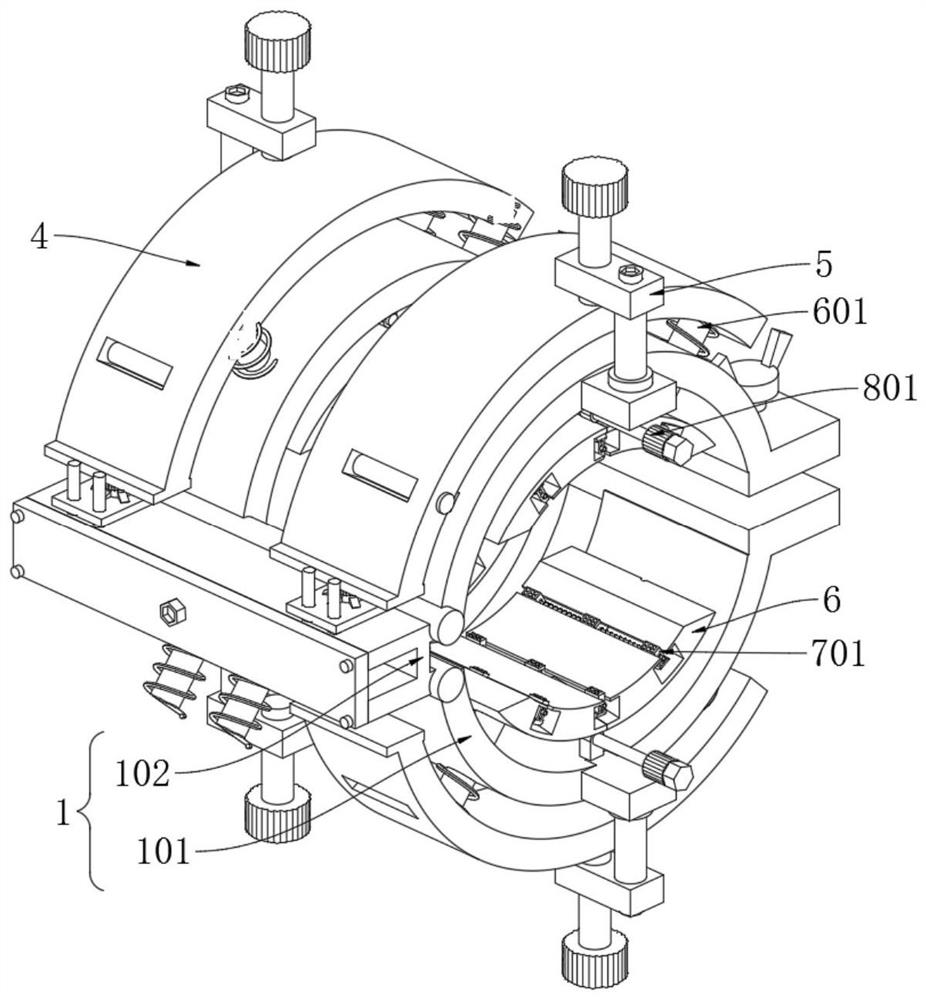

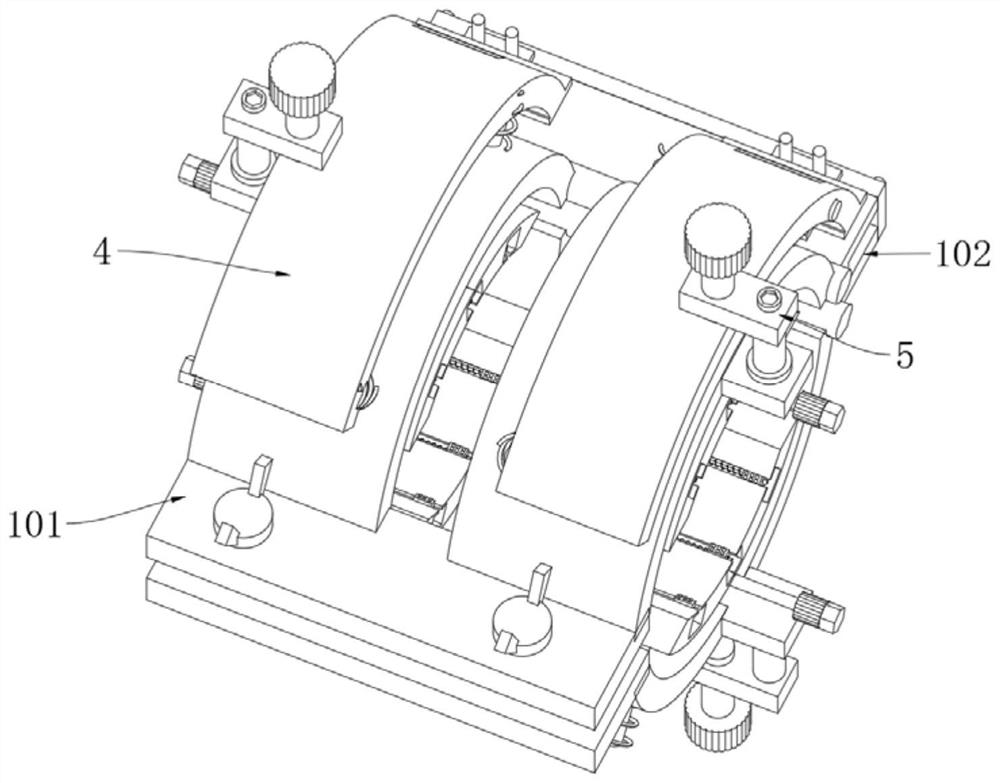

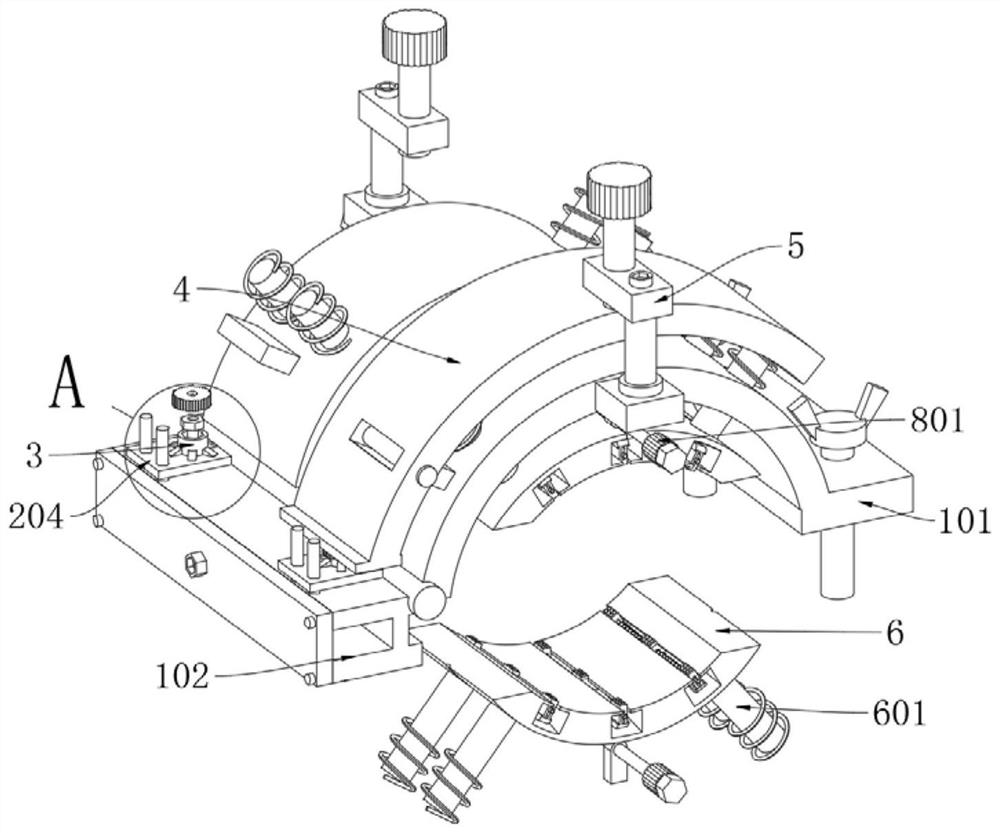

[0037] as attached figure 1 To attach Figure 8 Shown:

[0038]The invention provides a butt joint machine for steel parts for steel structure assembled building frame construction, which includes a wrapping mechanism 1; a rectangular baffle plate with a rectangular structure is installed on one side of the two wrapping mechanisms 1, and the two wrapping mechanisms 1 are connected by a The seat is rotated and connected, and the other end of the wrapping mechanism 1 is equipped with a wing bolt for easy clamping; the wrapping mechanism 1 includes a wrapping frame 101 and a connecting plate 102, and the wrapping frame 101 of the arc structure is symmetrically provided with two stop bars. 601 matched through holes, and a rectangular connecting plate 102 is installed on the parcel rack 101, and a gap for pipe welding is provided between the two parcel racks 101. When in use, the parcel rack 101 is convenient for wrapping the pipe, and the connecting plate 102 plays a role in sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com