Traction device for aluminum alloy extrusion aftertreatment

A technology of traction equipment and aluminum alloy, which is applied in the field of aluminum alloy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

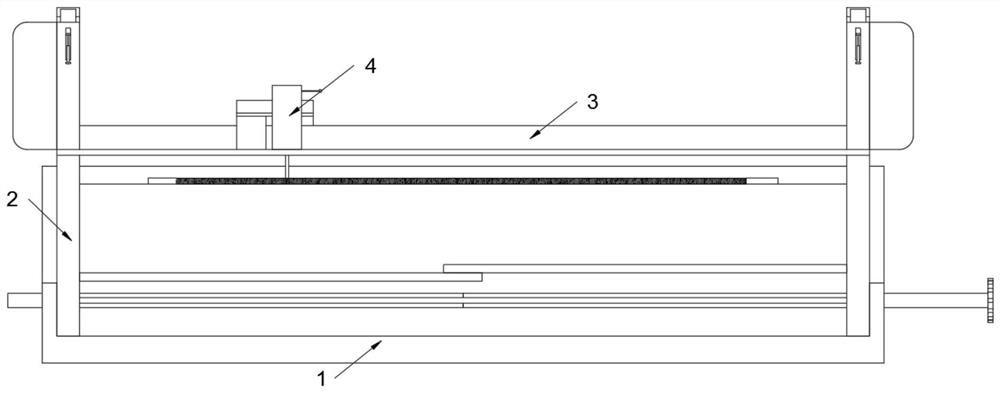

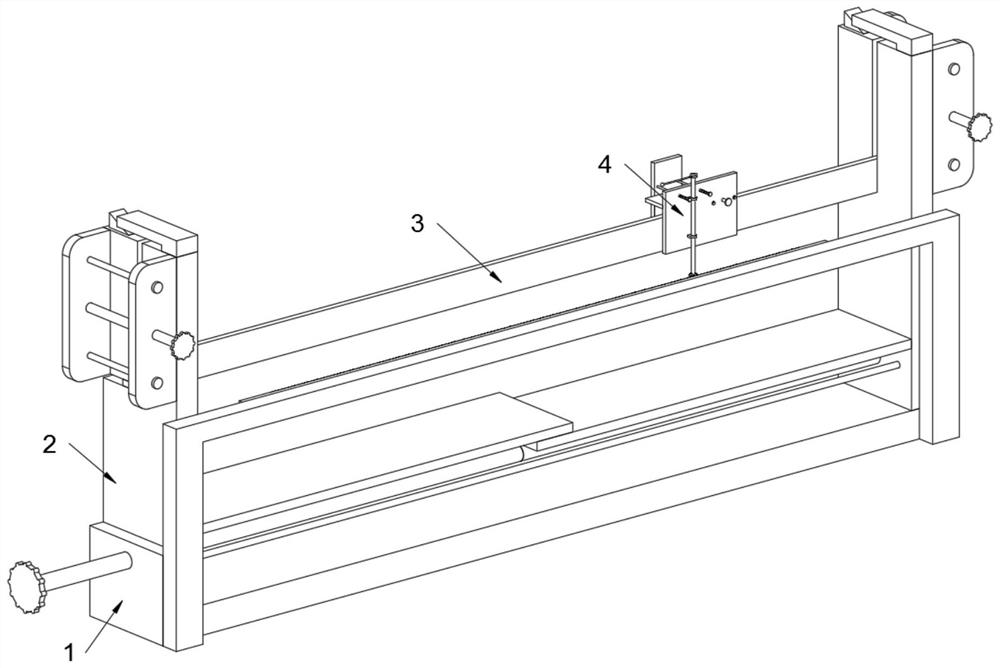

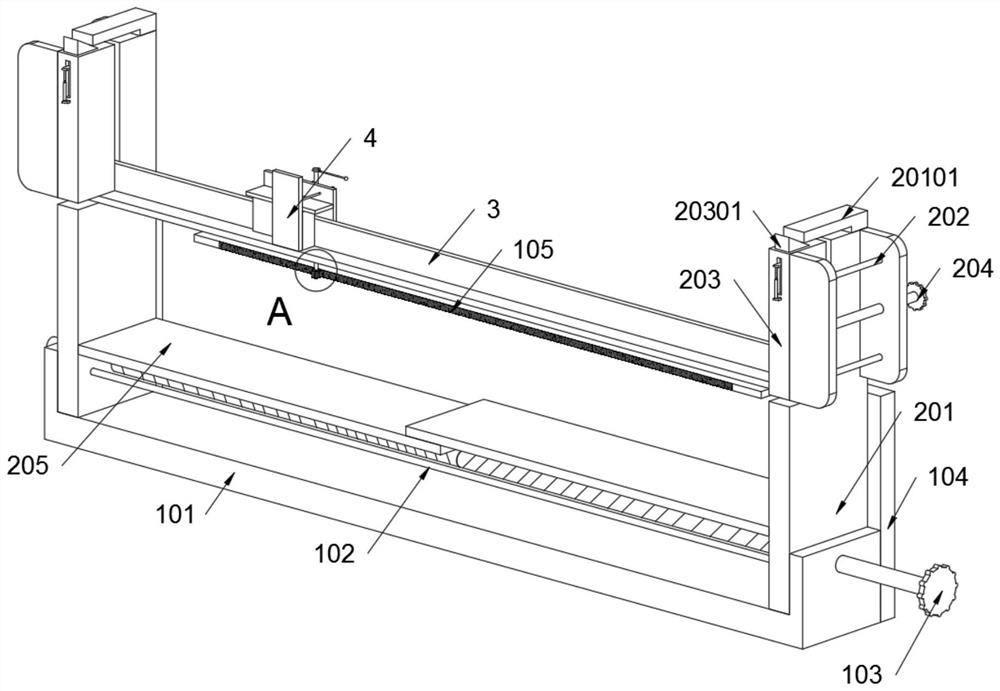

[0034] as attached figure 1 to attach Figure 8 Shown:

[0035] The present invention provides a traction device for post-extrusion processing of aluminum alloy, comprising a stretching frame structure 1, a clamp body seat 201 and a clamping block 203; a clamping structure 2 is installed on the stretching frame structure 1, and the clamping structure 2 An aluminum alloy strip 3 is clamped on the top, and a correction structure 4 is clamped on the aluminum alloy strip 3; refer to for example Figure 8 , the clamp body seat 201 includes a limit block 20101, and a limit block 20101 is welded on the clamp body seat 201; the clamp block 203 includes a top block 20301, and a top block 20301 is elastically slidably connected in the clamp block 203; the top block 20301 The top surface is in contact with the limit block 20101, and the top surface of the top block 20301 has an inclined structure, so that when the threaded rod A204 is screwed and adjusted, the top block 20301 is in a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com