Automatically closed monorail hinge by means of gravity

A self-closing, gravity technology, applied in the direction of wing closers, lighting and heating equipment, door/window accessories, etc., can solve the problems of increasing manufacturing costs, occupying installation space, lack of market competitiveness, etc., and achieve simplified overall structure size , Small installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

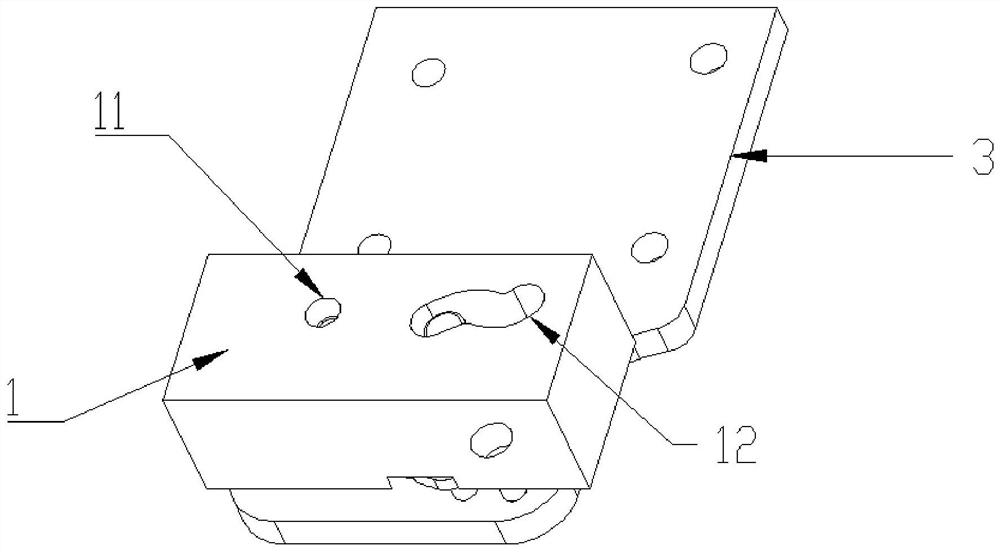

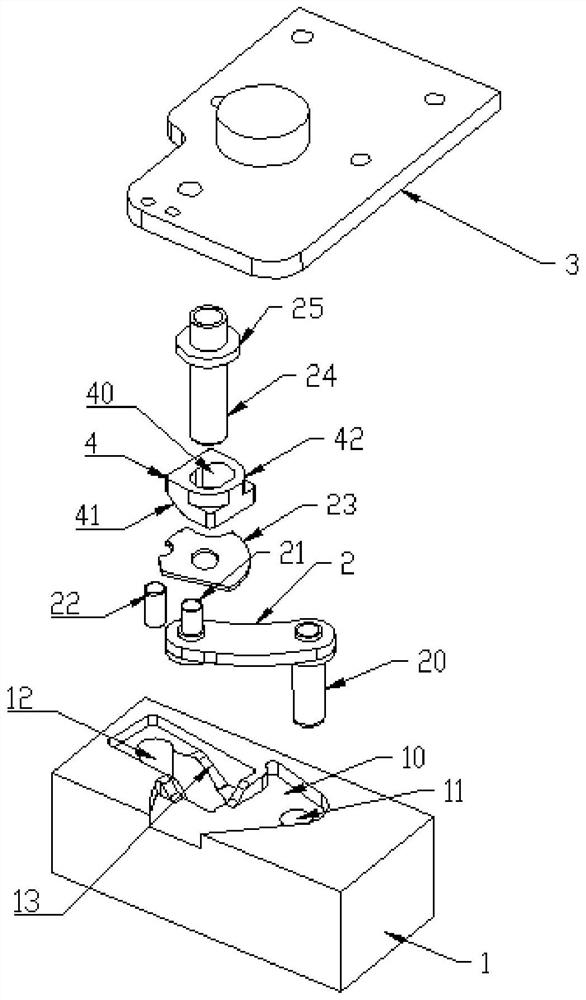

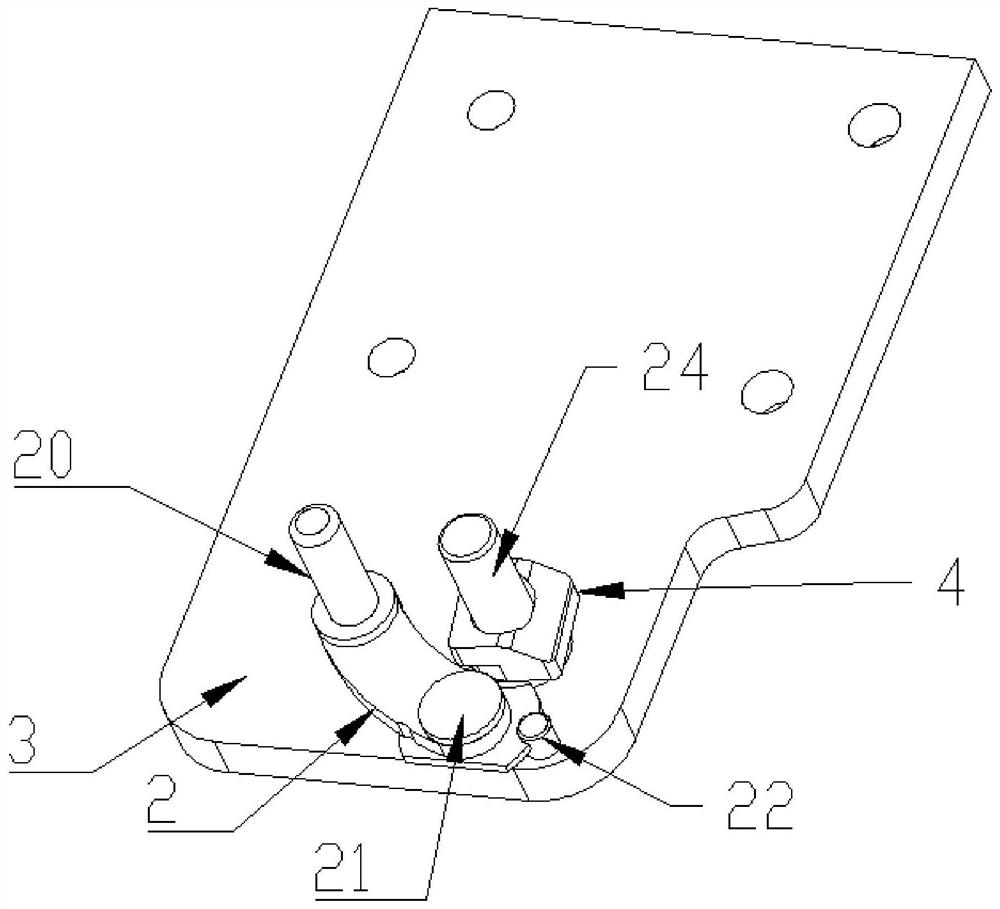

[0023] see Figure 1-8 , in an embodiment of the present invention, a gravity self-closing monorail hinge, including a mounting plate 3 for horizontally installing at the bottom of the hinged side of the box body 5 and a door slot block for installing at the bottom of the hinged side of the door body 50 1. The door slot block 1 is provided with a rotating slot 10, and the two sides of the bottom of the rotating slot 10 are respectively provided with a fixed shaft block hole 11 and a shaft sliding bending slot 12. The top surface of the mounting plate 3 is vertically spaced from front to back. A gasket shaft 21 and a sliding shaft 24 are fixed, and the top of the sliding shaft 24 is slidably inserted into the shaft sliding bending groove 12, and a connecting plate 2 is provided on the rod wall of the gasket shaft 21 for horizontal rotation. The top surface of the outer end is rotated and fixed with a fixed shaft 20, and the top of the fixed shaft 20 is slidably inserted into th...

Embodiment 2

[0029] The difference between this embodiment and embodiment 1 is:

[0030] The side wall of the outer end of the connecting plate 2 is set in a circular arc shape, and the side wall of the gravity slider 4 is provided with a plate corner arc surface 42 matched with the outer end of the connecting plate 2, and the set plate corner arc The surface 42 and the outer end of the arc-shaped connecting plate 2 are mainly to prevent the connecting plate 2 and the gravity slider 4 from rotating without interfering with each other and preventing misalignment and collision.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com