Valve block of electronic throttle valve, electronic throttle valve and valve block assembling method

An electronic throttle valve and assembly method technology, applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve the problem of cumbersome tooling replacement, simplify the assembly process, avoid sharp edges and corners, and prevent valve plates from scratching gas Tao effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

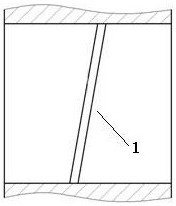

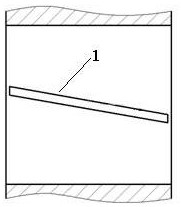

[0040] Figure 9 with Figure 10 The structure of the existing electronic throttle plate is shown. Such as Figure 9 with Figure 10As shown, the side of the valve plate 1 of the existing electronic throttle is formed by a slope 10 . Moreover, the installation directions of the electronic throttle valve plates of gasoline engines and diesel engines are also different.

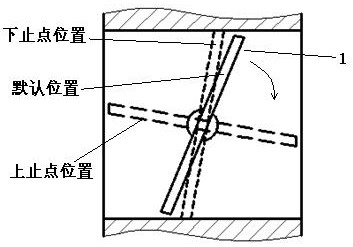

[0041] Figure 11 with Figure 12 The structure of the valve plate of the electronic throttle according to the first embodiment of the present invention is shown. The outer surface of the valve plate 1a according to the first embodiment of the present invention is composed of a first slope 11 and a second slope 12, the first slope 11 and the second slope 12 are inclined toward one side of the valve plate, and are symmetrical to each other, forming a V Shape symmetrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com