Photovoltaic module structure and processing technology

A photovoltaic module and integrated technology, applied in the direction of photovoltaic modules, photovoltaic power generation, electrical components, etc., can solve the problems of short service life, high cost, inconvenient assembly, etc., and achieve the goal of improving the discharge and release speed, increasing the service life and ensuring the working effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

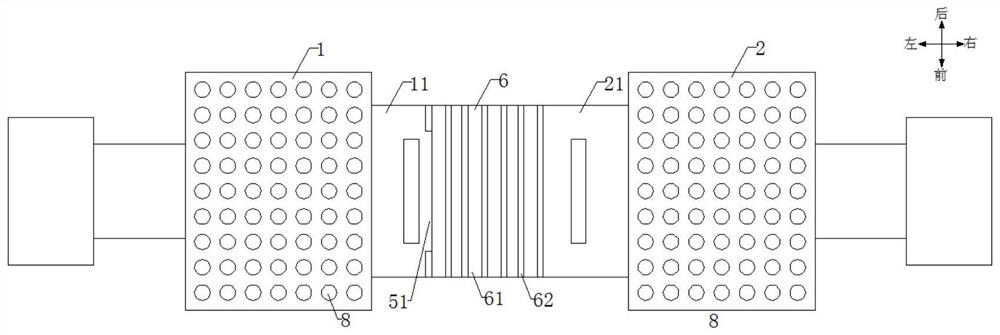

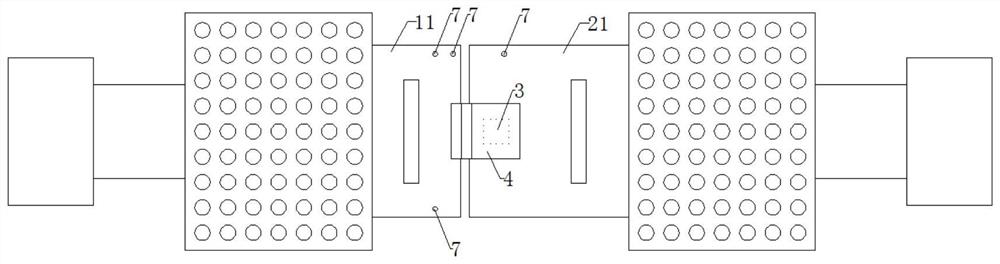

[0038] Such as Figure 1-4 As shown in and 7, a photovoltaic module includes a first frame 1 and a second frame 2 made of copper, a chip 3, a jumper 4, and a package body 5 for enclosing the chip 3 and the jumper 4, the first The right end of a frame 1 is provided with a first protrusion 11, and the left end of the second frame 2 is correspondingly provided with a second protrusion 21, and the chip 3 is arranged on the second protrusion 21, and the chip 3 is connected to the The first protrusion 11 is electrically connected, and the upper surface and / or lower surface of the package body 5 is provided with a heat dissipation device 6, and the heat dissipation device 6 includes a substrate 61 made of aluminum alloy, and the substrate 61 is connected to the package body through a thermally conductive adhesive. 5, the first frame 1 and the second frame 2 are provided with several frame through holes 8.

[0039] A heat sink 62 made of aluminum alloy is disposed on the substrate 61...

Embodiment 2

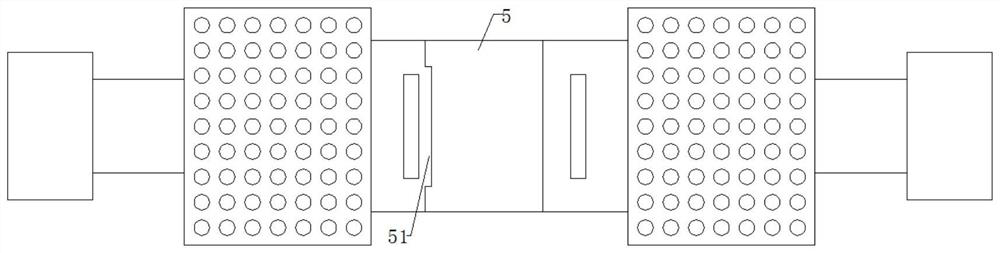

[0056] Such as Figure 5-7 As shown, a photovoltaic module includes a first frame 1 and a second frame 2 made of copper, a chip 3, a jumper 4, and a package 5 for sealing the chip 3 and the jumper 4. The first frame The right end of 1 is provided with a first protrusion 11, and the left end of the second frame 2 is correspondingly provided with a second protrusion 21, and the chip 3 is arranged on the second protrusion 21, and the chip 3 is connected to the first through a jumper 4. The protrusion 11 is electrically connected, and the upper surface and / or the lower surface of the package body 5 is provided with a heat sink 6, and the heat sink device 6 includes a substrate 61 made of aluminum alloy, and the substrate 61 is connected to the package body 5 through thermal conductive glue. Surface bonding, the first frame 1 and the second frame 2 are provided with several frame through holes 8 .

[0057] On the surface of the substrate 61 away from the package body 5 , heat diss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com