Convenient equipment overhaul inlet structure

A technology for equipment maintenance and entrance, which is applied to mechanical equipment, engine seals, engine frames, etc. It can solve the problems of laborious opening of the cover plate, large cover plate volume, and difficulty in moving, etc., to improve the sealing performance and the overall structure is simple and stable , the effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

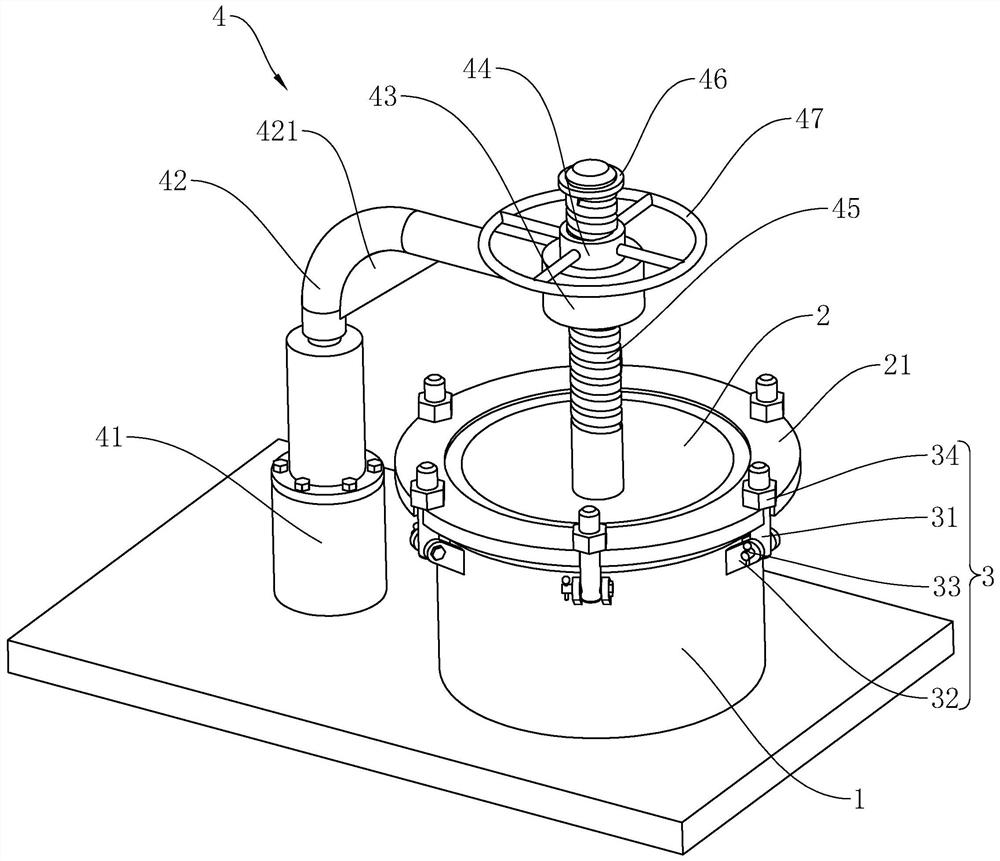

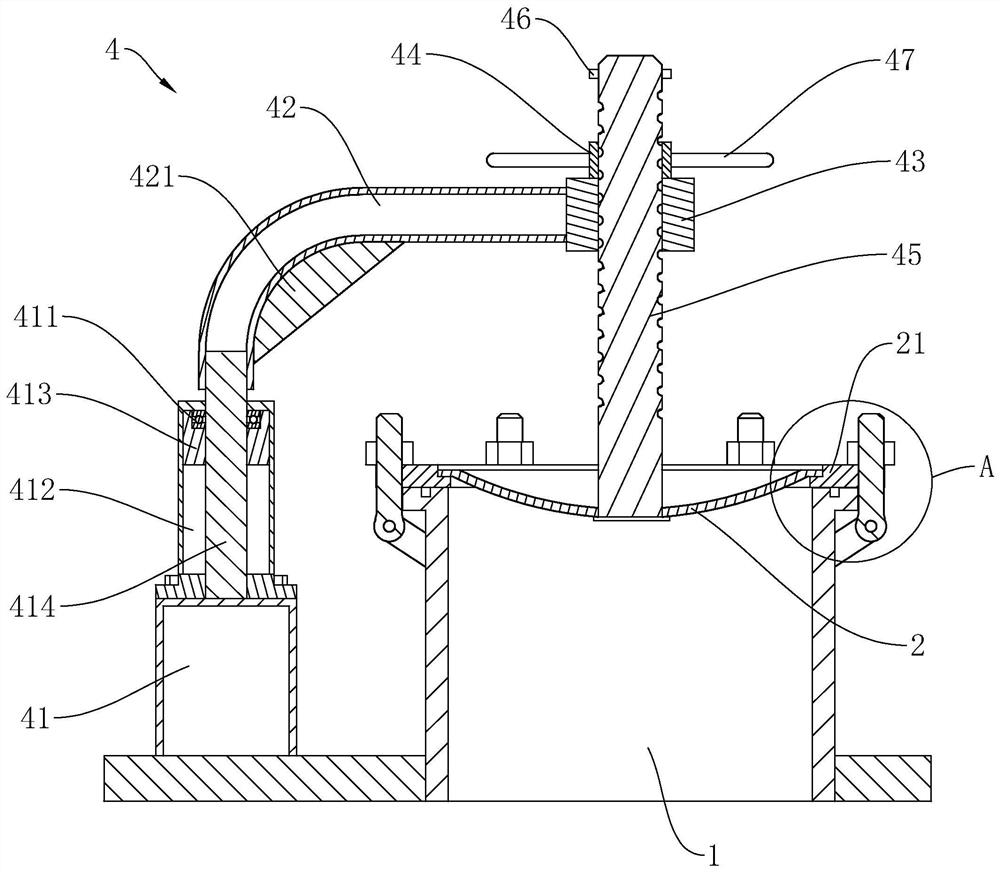

[0041] refer to figure 1 The equipment maintenance entrance structure includes a maintenance pipeline 1, a cover plate 2 arranged at the end of the maintenance pipeline 1 away from the equipment, a plurality of locking pieces 3 arranged between the cover plate 2 and the maintenance pipeline 1, and a A lifting mechanism 4 for driving the cover plate 2 to move.

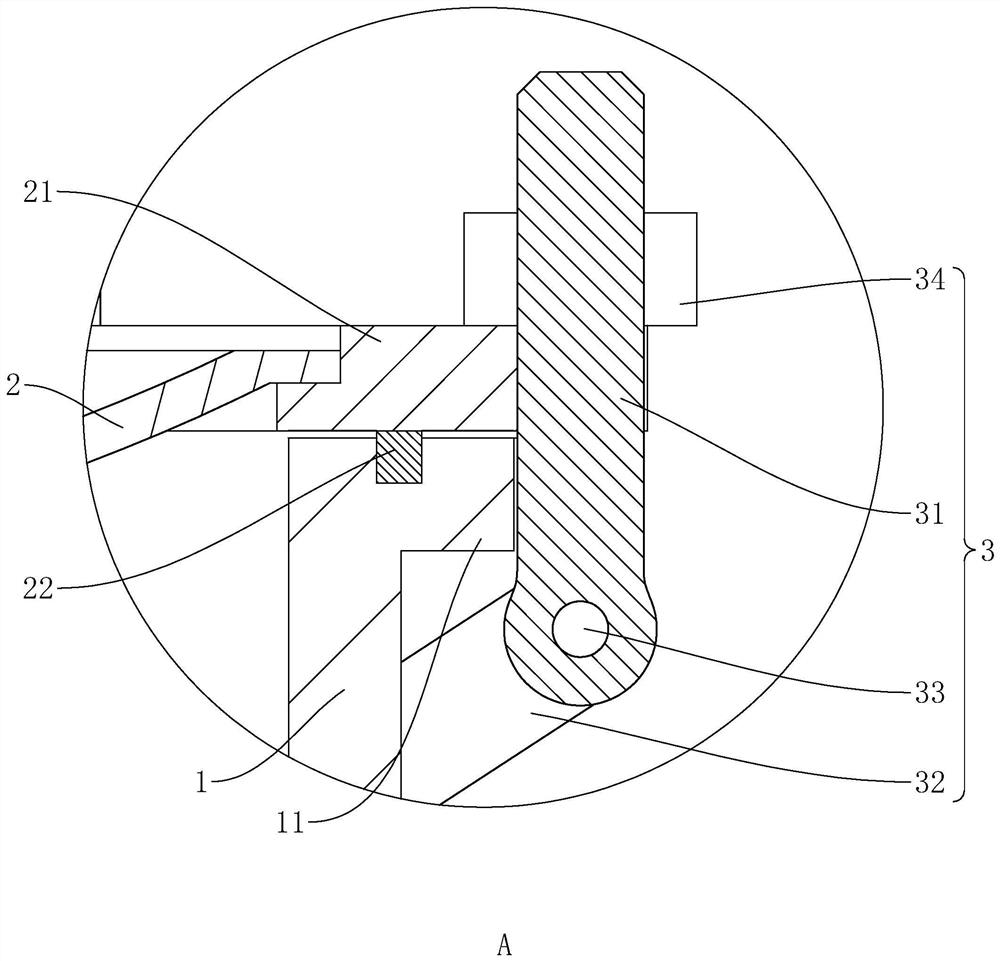

[0042] refer to figure 1 and figure 2 The maintenance pipeline 1 is arranged as a hollow circular pipeline inside, and the maintenance pipeline 1 is welded vertically on the shell or frame of the equipment, and communicates with the inside of the equipment; the cover plate 2 is set at the top opening of the maintenance pipeline 1, and the The top opening of the maintenance pipeline 1 is closed, and the flange 21 is welded on the side wall of the cover plate 2 along its circumference, that is, the flange 21 is arranged in a ring; Distributed at even intervals, a plurality of locking parts 3 cooperate with the flange ...

Embodiment 2

[0051] The difference between this embodiment and Embodiment 1 is that the main shaft 414 is provided with a limiting disk 5 .

[0052] refer to Figure 6 , the limit plate 5 is located inside the seat body 412, and the limit plate 5 is sleeved on the main shaft 414 and fixedly connected with it, the diameter of the limit plate 5 is smaller than the inner diameter of the seat body 412; the limit plate 5 is provided with a limit groove 51, Limiting groove 51 is arc-shaped setting, and the curved axis of limiting groove 51 coincides with the axis of seat body 412; The inner side walls are arranged at intervals, and the limiting block 52 slides in the limiting groove 51 . When the cover plate 2 is placed on the maintenance pipeline 1 , the limiting block 52 abuts against one end inner wall of the limiting groove 51 .

[0053] The implementation principle of Embodiment 2 is: when the main shaft 414 rotates, it will drive the limit disc 5 to rotate together. When the limit block 5...

Embodiment 3

[0055] The difference between this embodiment and Embodiment 1 is that the installation position of the hand wheel 47 is different.

[0056] refer to Figure 7 and Figure 8 , one end of the support rod 42 located above the cover plate 2 is fixed with a transmission box 48, the transmission box 48 is arranged in a hollow shell, the threaded sleeve 44 is rotatably connected to the rotary box, and the screw rod 45 is threaded in the threaded sleeve 44 ; The handwheel 47 is rotatably connected on the side wall of the transmission box 48, and the axis of the handwheel 47 is perpendicular to the axis of the threaded sleeve 44. A transmission assembly 49 is arranged between the handwheel 47 and the threaded sleeve 44, and the handwheel 47 The threaded sleeve 44 can be driven to rotate by the transmission assembly 49 .

[0057] refer to Figure 8 The transmission assembly 49 includes a worm 491 rotatably connected in the transmission box 48, and a worm wheel 492 sleeved on the thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com