Clamping detection device for miniature bearing nylon retainer

A technology of miniature bearings and detection devices, which is applied in the field of bearing parts, can solve problems such as low efficiency, inconvenient operation, and poor operational stability, and achieve the effects of convenient use, high accuracy, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

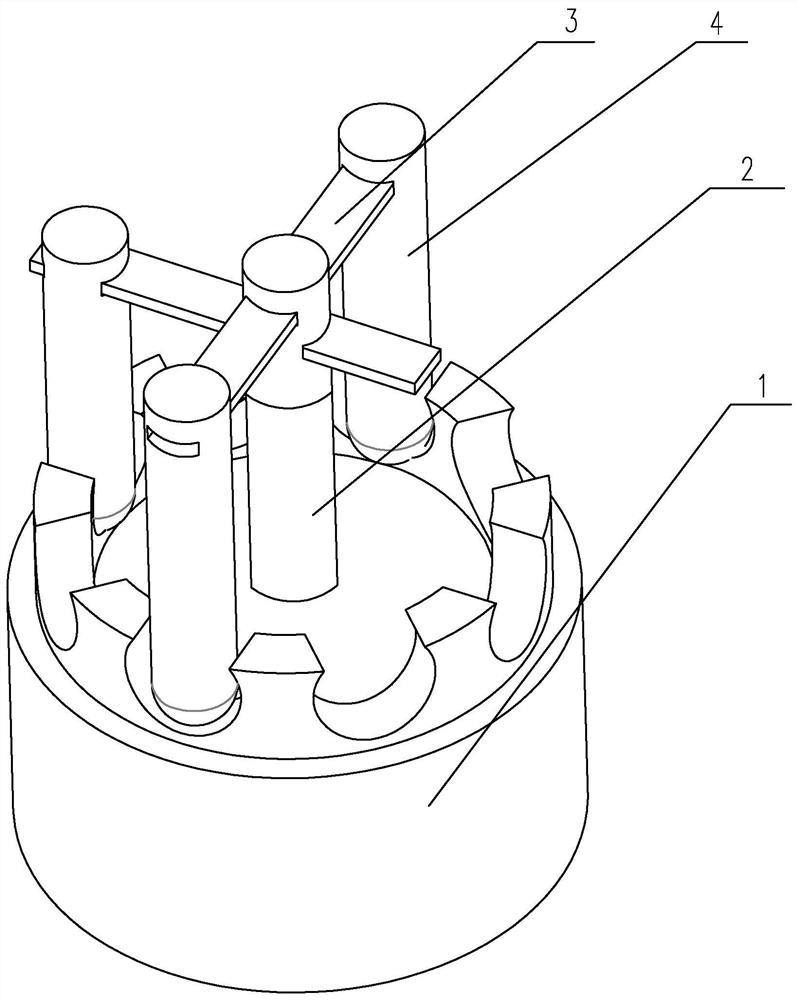

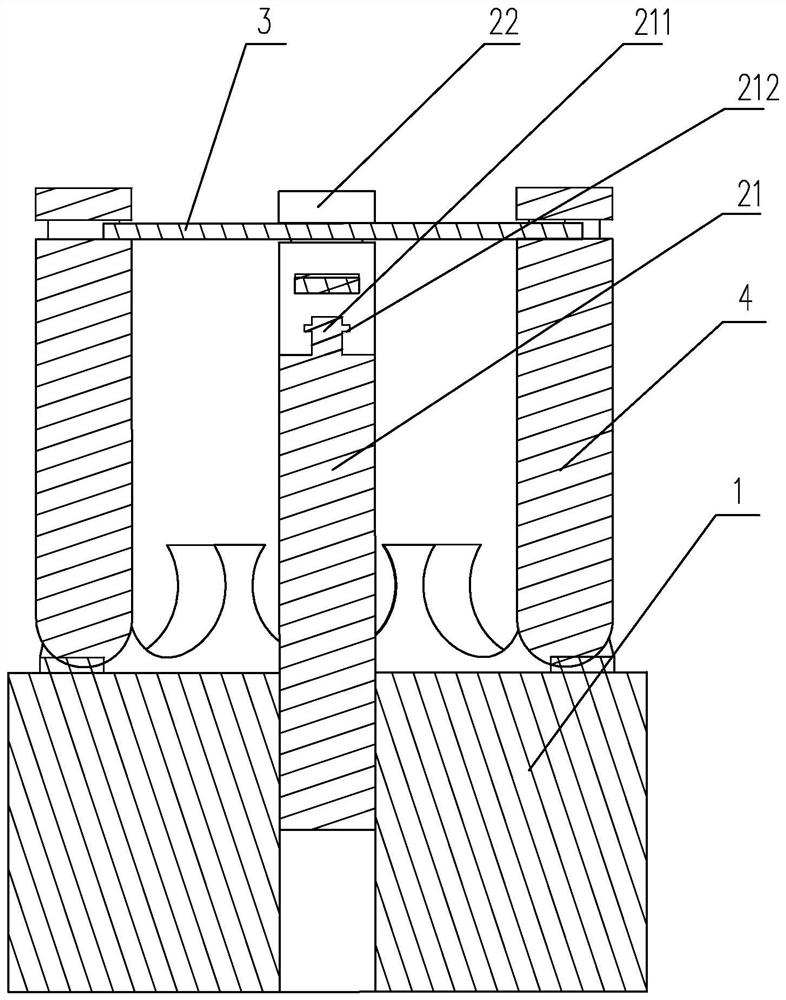

[0014] Examples of the clamping detection device for the miniature bearing nylon cage of the present invention are as follows: figure 1 , figure 2 As shown: it includes a base 1 and at least two pressing rods 4. The base 1 is provided with a positioning post 2, and the positioning post 2 is provided with elastic force for making the pressing rod 4 interfere with the pocket of the nylon cage to be positioned. One end of the pressing rod 4 is connected to the positioning column 2 through the elastic sheet 3, and the other end of the pressing rod 4 is arranged as a ball head. The beneficial effect of such setting is: setting in this way, the nylon cage is placed on the base 1, and the ball head of the pressure rod 4 is interfered in the pocket of the cage through the pressure rod 4 arranged on both sides of the positioning column 2, thereby realizing The positioning of the nylon cage is convenient for the inspector to detect the roundness and contour. At the same time, the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com