Defect detection network construction method, anomaly detection method and system, and storage medium

A construction method and defect detection technology, applied in the field of image processing, can solve problems such as large number of good product samples, inability to meet real-time detection and distributed detection requirements, and high computing overhead

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

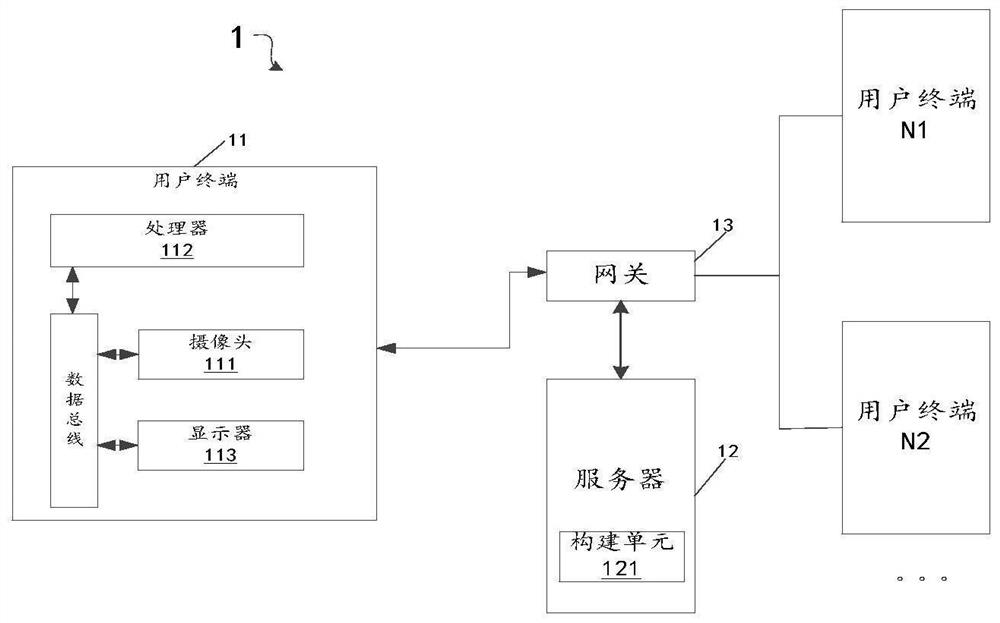

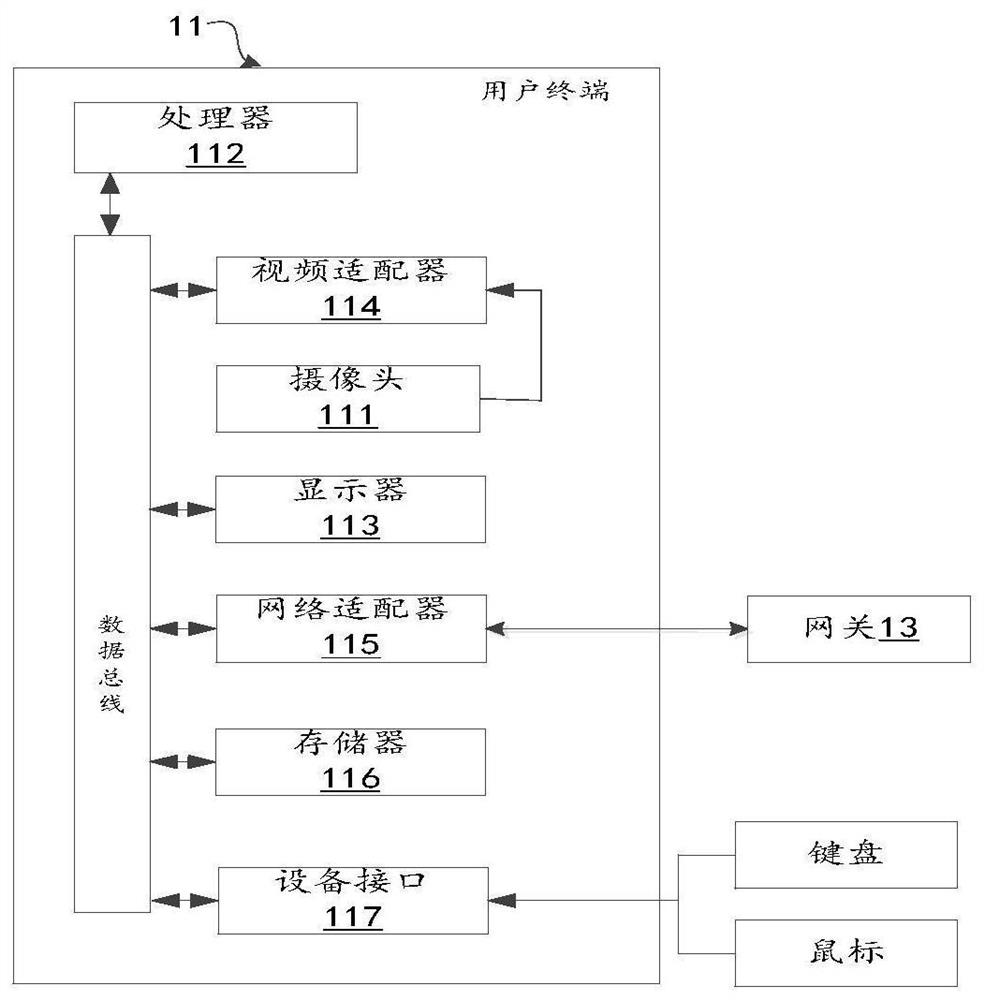

[0047] Please refer to figure 1 , this embodiment discloses a defect detection system, the defect detection system 1 includes at least one user terminal 11, and each user terminal 11 is used to perform defect detection on the object to be detected passing on the conveying channel. Here, the user terminal 11 includes a camera 111 , a processor 112 and a display 113 .

[0048] In this embodiment, the user terminal 11 may be a detection device that is fixed or erected on the product transmission channel, and can perform defect detection on each product passing through the detection area. In some cases, the defect detection system may include multiple user terminals 11, so that they are set on different conveying channels of the same product, or on different conveying channels of products. In addition, the user can set the configuration parameters of each user terminal 11 to adapt to the working modes of different products, and can also view the results of defect detection.

[0...

Embodiment 2

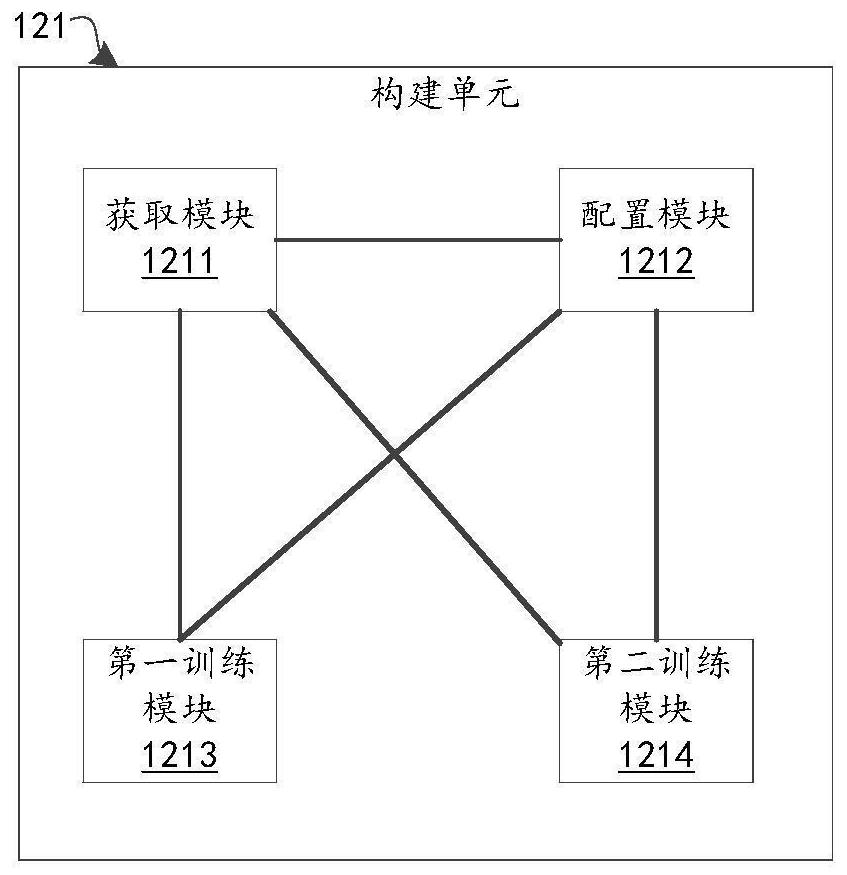

[0066] Please refer to figure 1 and image 3 , the construction unit 121 in the server 12 may specifically include an acquisition module 1211, a configuration module 1212, a first training module 1213 and a second training module 1214, which will be described respectively below.

[0067] The obtaining module 1211 is used to obtain the sample image in the preset open data set and the reference image of the standard product corresponding to the object to be detected. Open datasets can be ImageNet, COCO, PASCAL VOC and other datasets, preferably ImageNet datasets; open datasets can be set on the cloud or on a specific server, and the sample images can be retrieved only through network access. The reference image of the standard product corresponding to the object to be detected can be pre-stored on the user terminal or server, and the stored reference image data can be directly read.

[0068] The configuration module 1212 is connected with the acquisition module 1211, and is us...

Embodiment 3

[0086] In order to clearly understand the construction process of the defect detection network, a method for constructing a defect detection network will be disclosed in this embodiment. The construction method can be applied to a server or a user terminal, and constitute a functional module of the server or user terminal (such as implementing As for the construction unit 121 in Example 1, it can be understood that the functional modules corresponding to the construction method need to be executed by a processor to realize the corresponding functions.

[0087] Please refer to Figure 5 , The method for constructing the defect detection network for which protection is claimed includes steps S110-S160, which are described below respectively.

[0088] Step S110, acquiring the sample image in the preset open data set and the reference image of the standard product corresponding to the object to be detected.

[0089] It should be noted that open datasets can be ImageNet, COCO, PAS...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com