Method for monitoring connection correctness of oil discharging pipe based on multi-camera linkage

A multi-camera, correctness technology, applied in neural learning methods, television, biological neural network models, etc., can solve problems such as high labor cost, high risk of error, and inability of superior leaders to supervise and manage, so as to facilitate supervision and management, reduce The effect of human cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

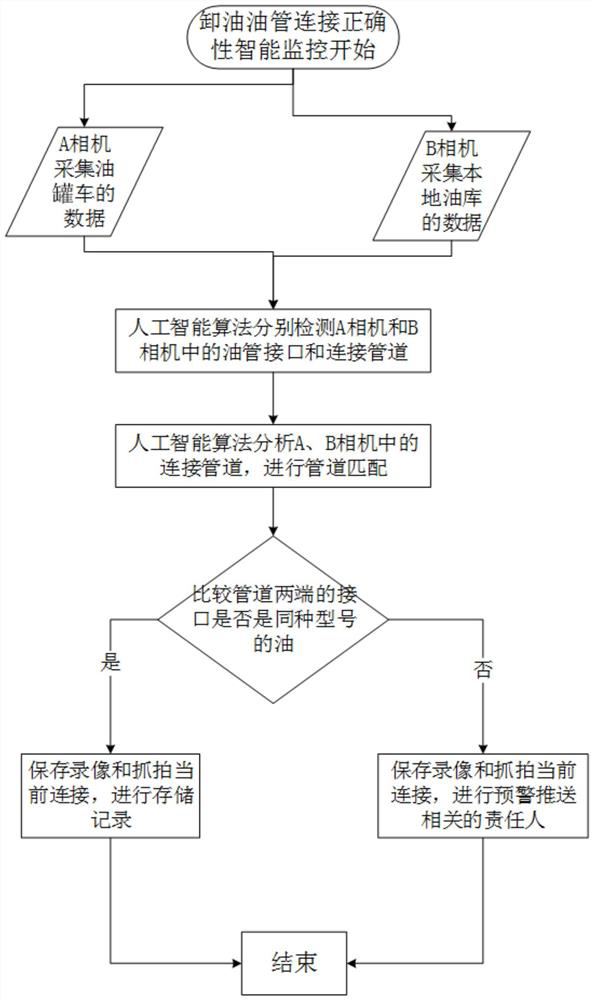

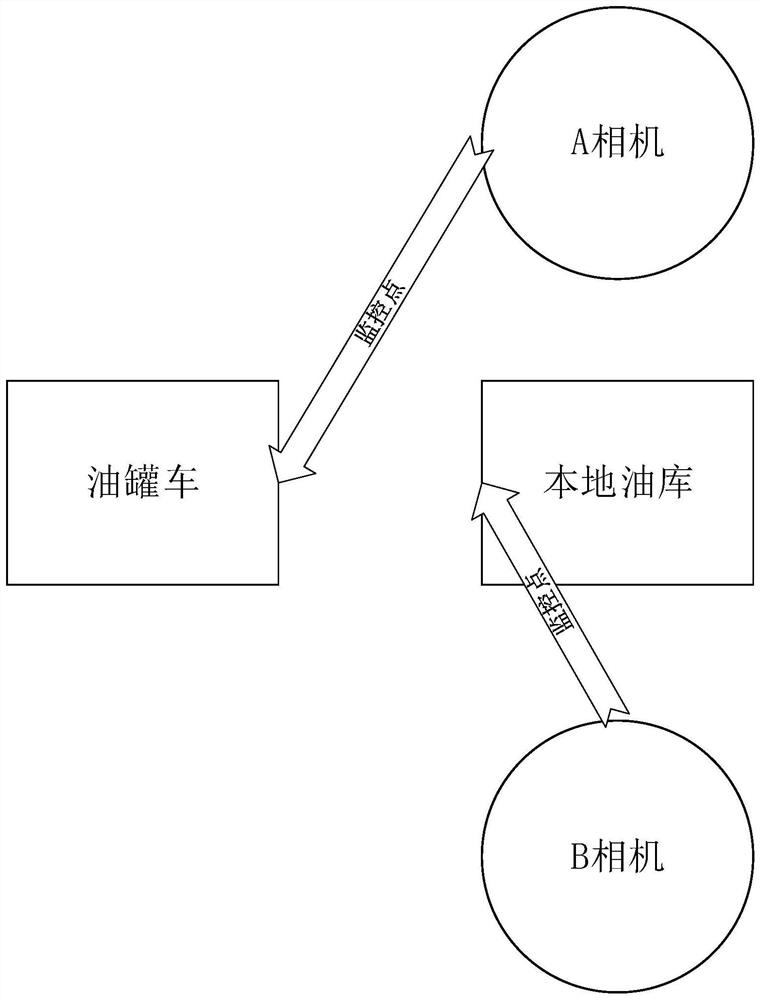

[0037] Such as figure 1 As shown, the present invention is a method for monitoring the correctness of the oil discharge pipe connection based on multi-camera linkage, including:

[0038] S1: Set up several monitoring devices in the unloading area of the gas station, collect data from the tanker and the local oil depot through the monitoring devices at different angles to obtain unloading videos, and obtain unloading images based on the unloading videos;

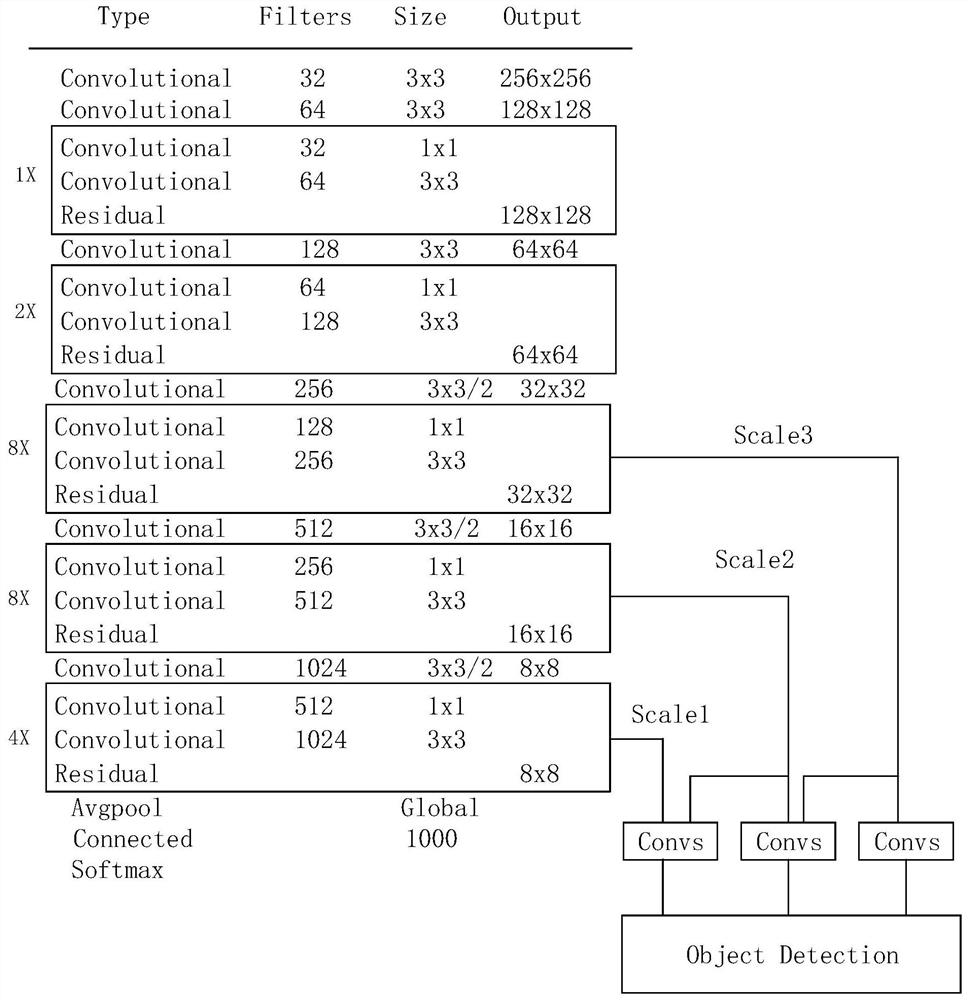

[0039] S2: Detect the oil unloading image through the convolutional neural network to obtain the oil unloading interface and the interface connecting pipeline; mark the oil type on the oil unloading interface to obtain the marking result of the oil type;

[0040] S3: Analyze and extract the interface connection pipeline through the convolutional neural network to obtain the characteristics of the interface connection pipeline. According to the extracted interface connection pipeline features, match the same pipeline under d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com