Tool jig for assembling surgical robot instrument connecting mechanism

A surgical robot and connecting mechanism technology, applied in the direction of surgical instrument support, surgical robot, hand-held tools, etc., can solve the problems of laborious and troublesome installation, and achieve the effect of easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

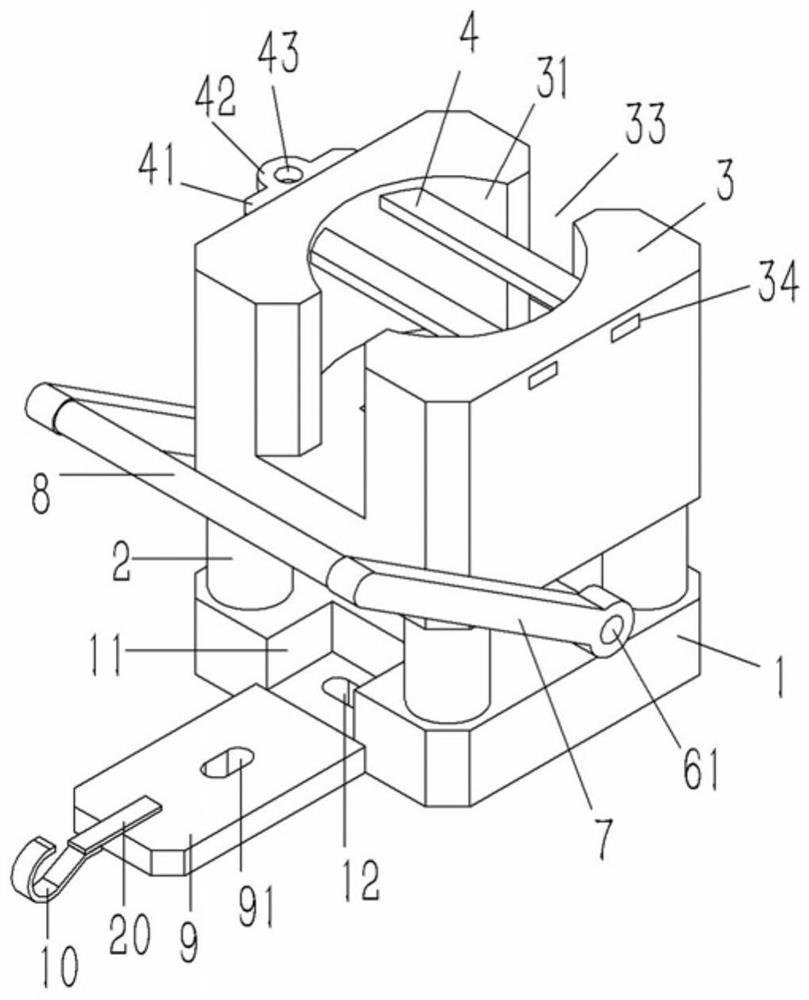

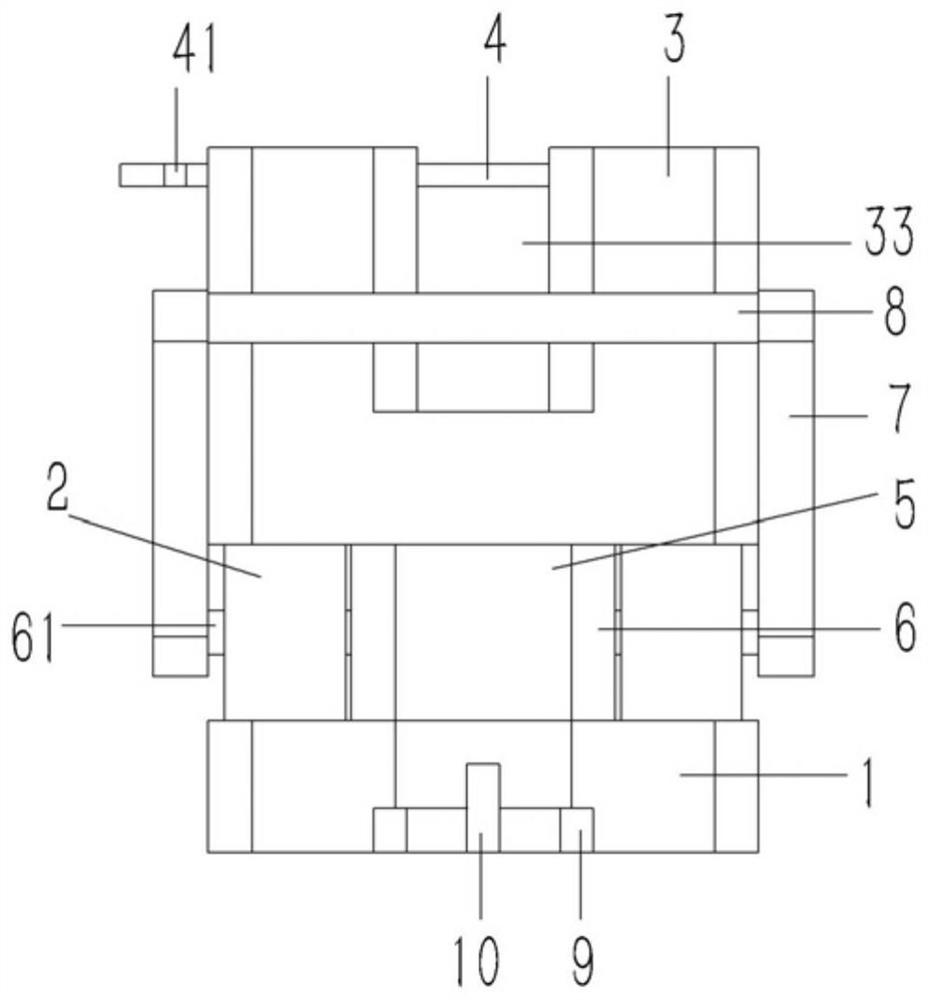

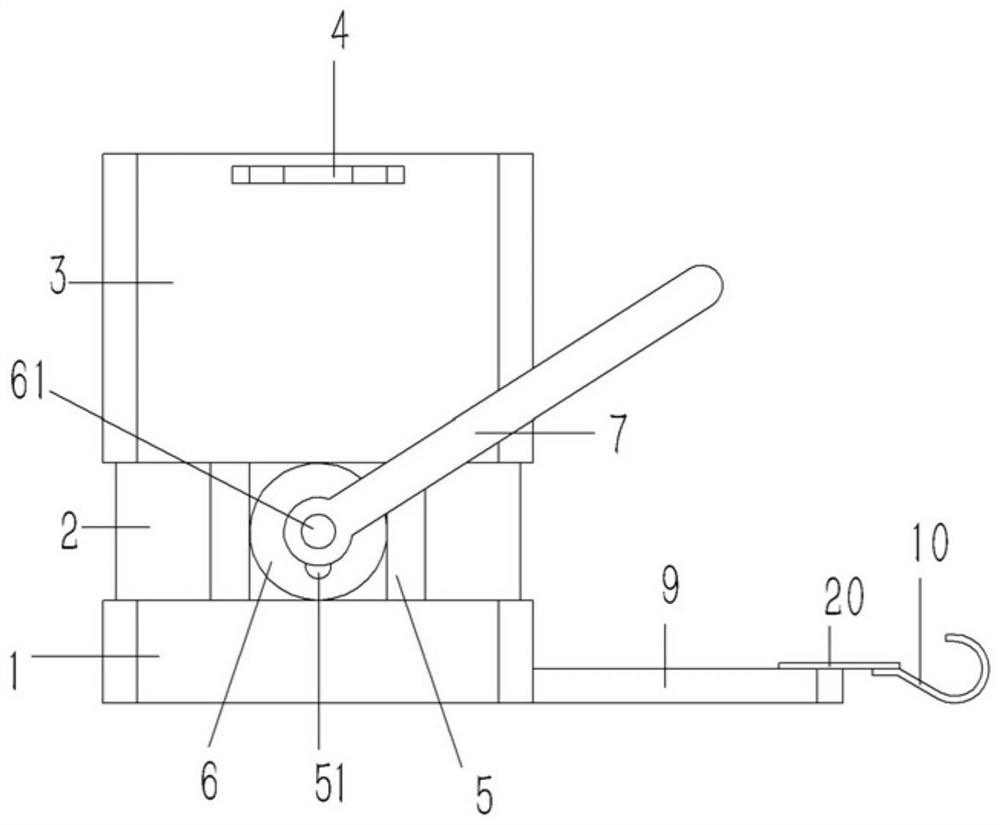

[0019] Example: see Figures 1 to 4 As shown, a tooling fixture for assembling the connection mechanism of surgical robot instruments includes a rectangular base 1, the four corners of the base 1 are fixed with columns 2, the upper end of the column 2 is fixed with a rectangular assembly base 3, and the upper end of the assembly base 3 A circular counterbore 31 is formed on the end surface, and a positioning hole 32 penetrating through the lower end surface of the assembly base 3 is formed on the bottom surface of the counterbore 31; The observation slot 33 on the front and rear end faces, the opposite inner walls on the left and right sides of the upper end of the counterbore 31 are formed with jacks 34 that run through the left and right end faces of the assembly base 3, and the jacks 34 of the assembly base 3 are plugged with Several retaining bars 4; the positioning hole 32 of the assembly base 3 is inserted with a vertical ejector block 5, the lower end of the ejector blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com