Anti-falling cargo hold area structure gap bridge platform

A cargo hold and platform technology, which is applied to ship components, ships, transportation and packaging, etc., can solve the problems of lack of cushioning structure of the guardrail, insufficient safety of the outfitting platform, and large impact damage, so as to achieve good use effect and prevent personnel from falling , Enhance the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

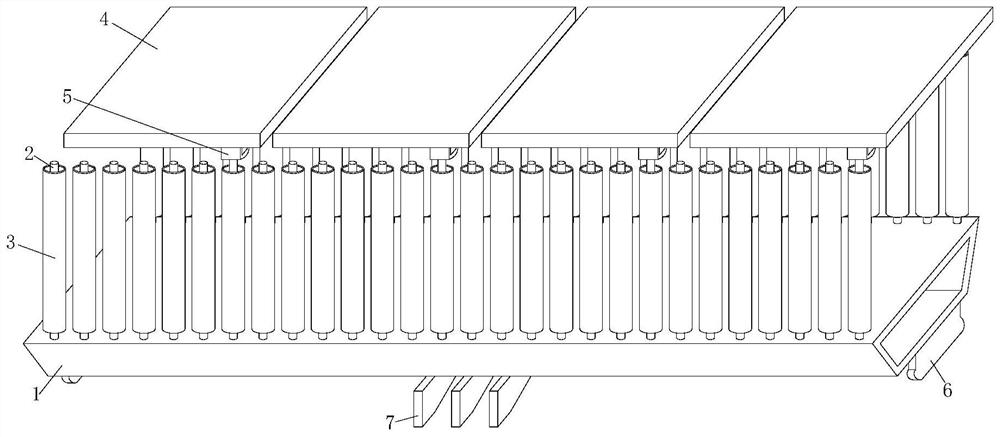

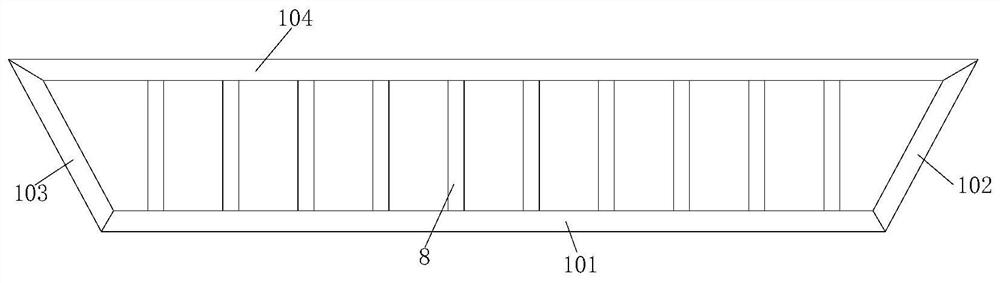

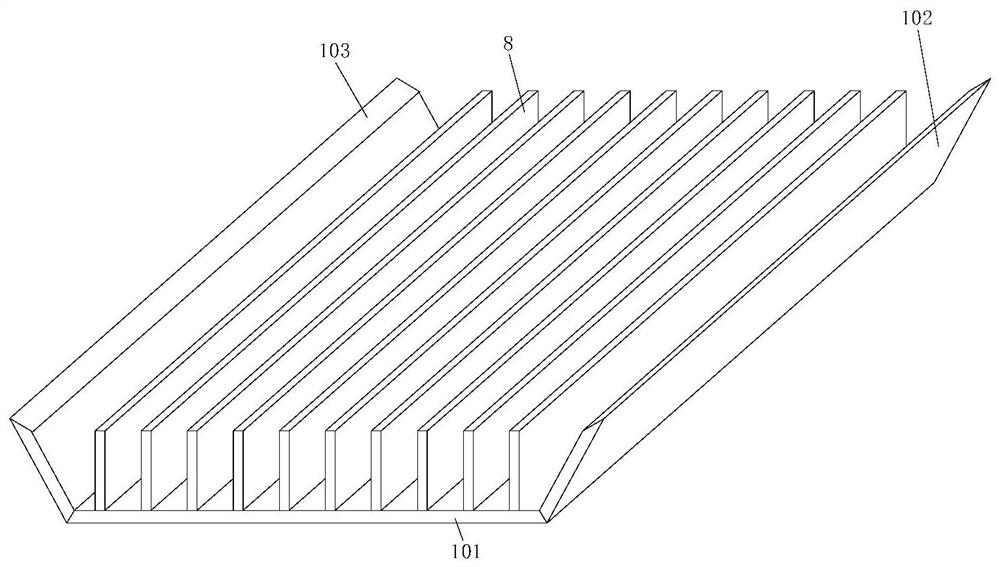

[0031] see Figure 1-7 As shown, a bridge crossing platform with an anti-slip cargo hold area structure includes a hollow bridge body 1, a protective blocking mechanism and a shielding and heat-insulating rotating plate 4. The number of the protective blocking mechanisms is several, and several of the protective blocking mechanisms Evenly distributed on the top of both sides of the hollow bridge body 1, a gap of 1-1.3 cm is formed between two adjacent protective blocking mechanisms;

[0032] The protective blocking mechanism includes a fixed vertical bar 2 and a movable circular sleeve 3 sleeved on the fixed vertical bar 2. The fixed vertical bar 2 is provided with several elastic connectors at equal intervals along the length direction. The fixed vertical bar 2 and the movable circular sleeve 3 are elastically connected through an elastic connector, and the outer wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com