Automatic panel stacking adjusting device and control method

A technology of automatic adjustment device and control method, applied in the direction of stacking receiving device, transportation and packaging, sending objects, etc., can solve the problems of adjustment misoperation, product quality defect, deficiency, etc., achieve shortened time and avoid product quality defect , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the features and advantages of this patent more obvious and easy to understand, the following special examples are described in detail as follows:

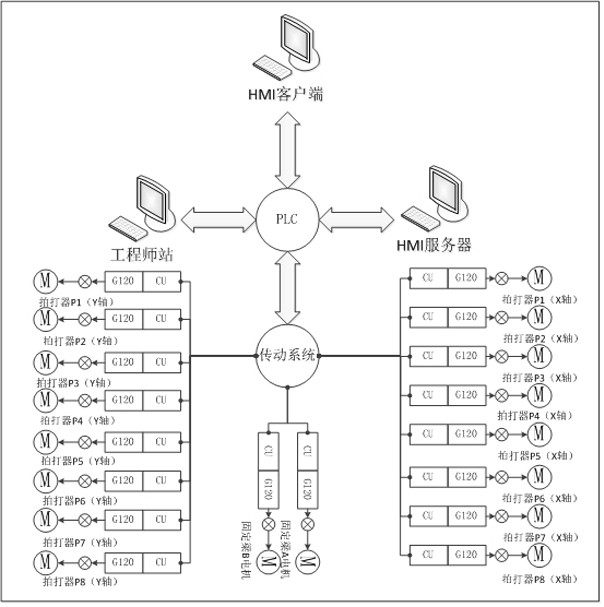

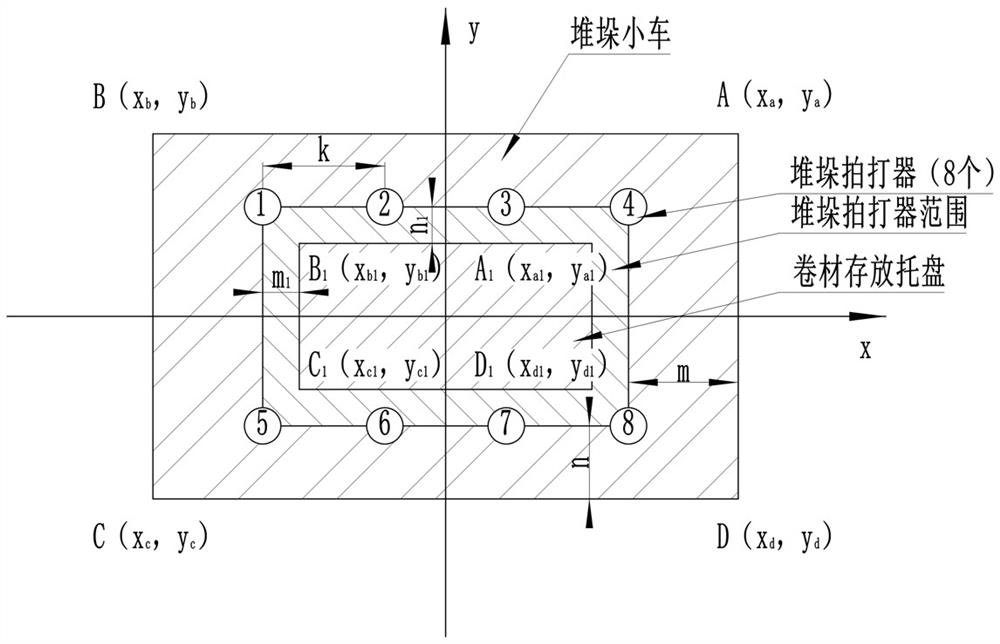

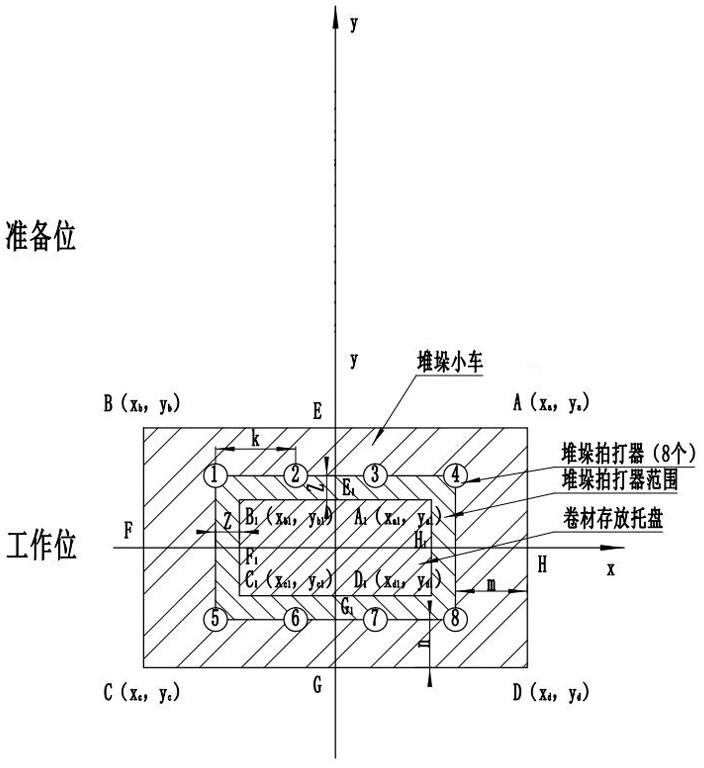

[0026] Such as Figure 1-Figure 4 As shown, the plan of the plate stacking automatic adjustment device provided in this embodiment includes: a stacking trolley, a plate storage tray, two sets of flappers, and a laser range finder.

[0027] Among them, the plate storage tray is placed on the platform on the top of the stacking trolley, and the edge is parallel to the working reference line. Each group of clappers includes four clappers. There are four laser range finders, which are respectively installed around the stacking trolley and aligned with the plate storage tray; two sets of flappers are respectively installed through the fixed beam; the fixed beam is parallel to the working reference line and has a Freedom of movement vertically and vertically. The flapper has a degree of freedom of translation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com