A heavy hammer ramming device

A heavy hammer and combined hammer technology, applied in construction, infrastructure engineering, grain processing, etc., can solve the problems of easy blockage of exhaust holes, low ramming efficiency of heavy hammers, and inability to automatically correct ground deflection, so as to avoid blockages. , avoid protrusion, improve the effect of compaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

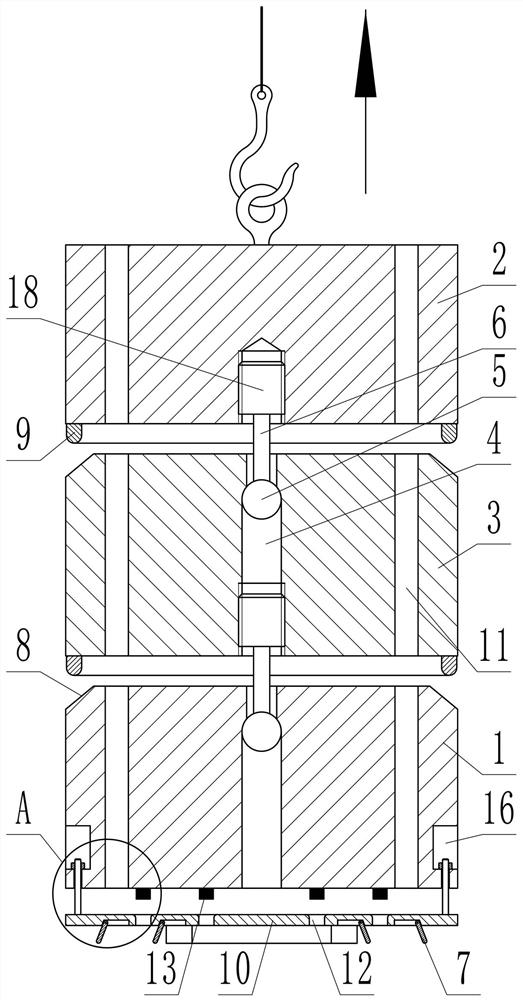

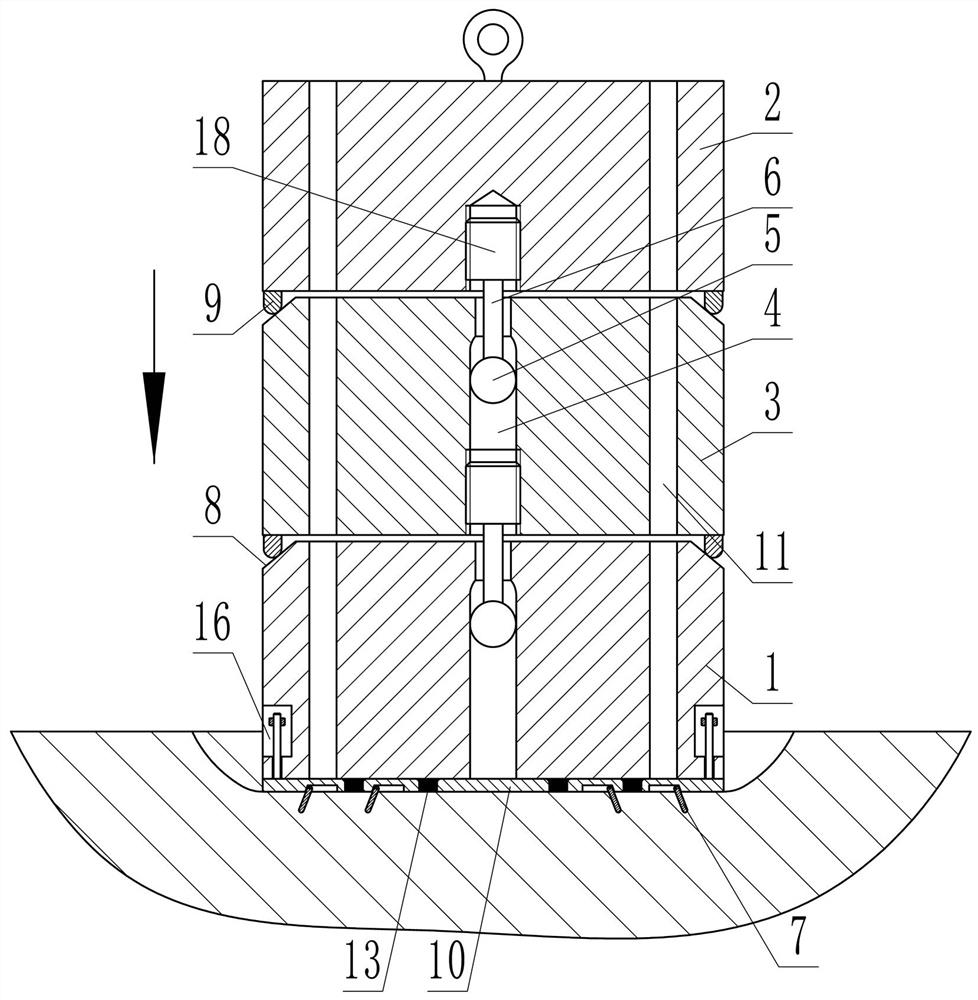

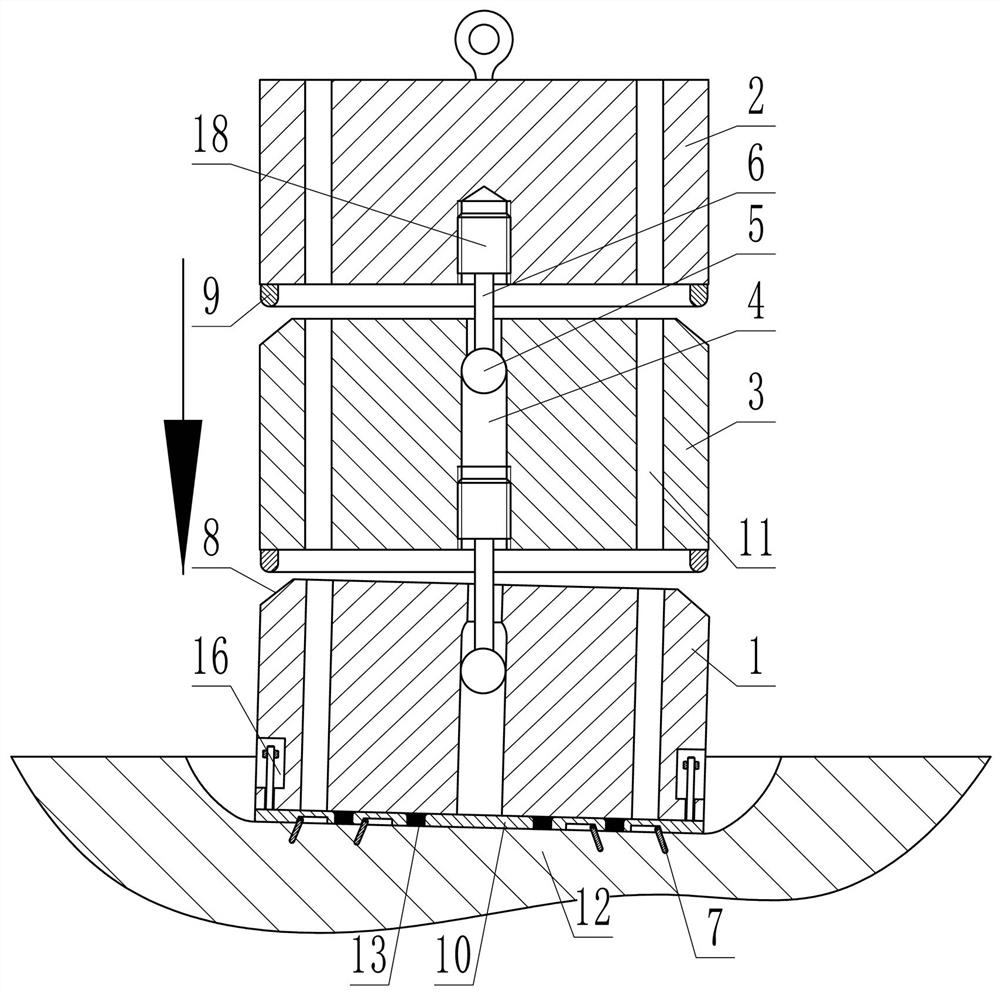

[0014] Depend on Figure 1 to Figure 7 Given, the present invention includes a combined hammer head, the combined hammer head includes a bottom block 1, a top block 2 and a plurality of middle blocks 3, the top block 2, middle block 3 and bottom block 1 are arranged sequentially from top to bottom; the top block 2. The bottom block 1 and the middle block 3 are both columnar structures, and the axis of the bottom block 1 and each middle block 3 has a two-stage stepped through hole 4 with the small end facing upwards. A sphere 5 is installed in the large diameter section, the diameter of the sphere 5 is greater than the diameter of the small diameter section of the through hole 4, the sphere 5 can slide and rotate in the through hole 4, and a vertical connecting rod 6 is fixed on the sphere 5, The connecting rod 6 stretch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com