Wind power main shaft bearing design calculation and model selection method and device

A design calculation and wind power spindle technology, which is applied in the field of wind power spindle bearing design calculation and selection methods and devices, can solve the problems of special operating conditions, loss of data volume, selection and calculation of bearing failure, etc., and achieves high calculation accuracy. Reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

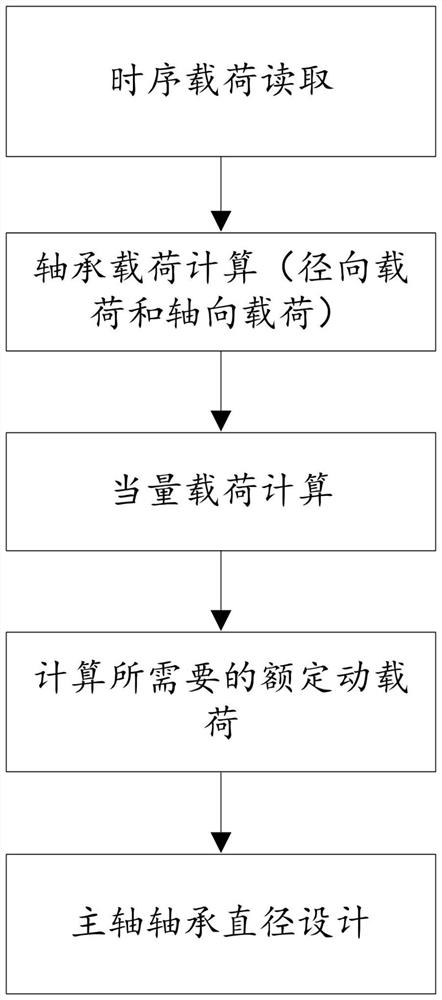

[0034] The process flow of wind power main shaft bearing design calculation and selection method based on time series is as follows: figure 1 shown.

[0035] Step 1: Read the timing load.

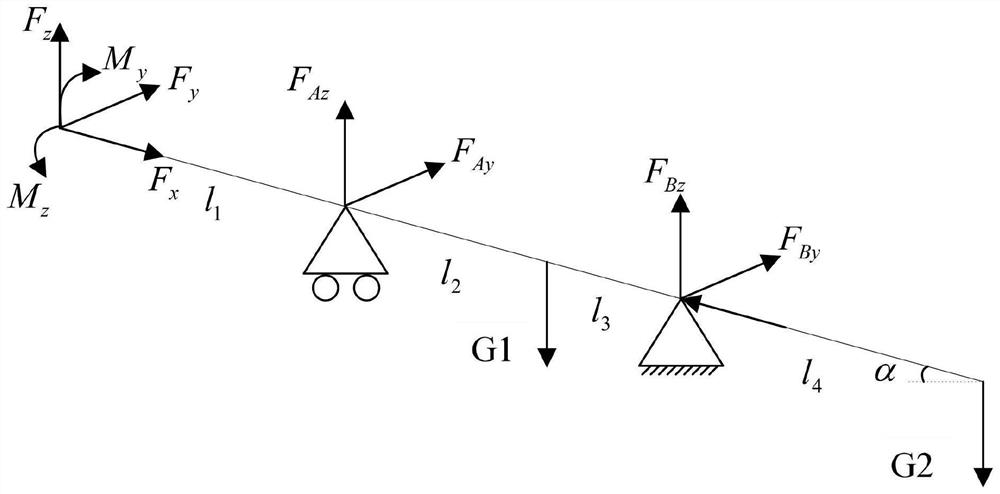

[0036] The time series load is the load statistical value under all working conditions within the 20-year design life cycle of the fan. The time series load should at least include the forces, moments, and operating revolutions acting on the center of the hub in all directions, F xi , F yi , F zi ,M xi ,M yi ,M zi is the impeller load corresponding to the i-th load step, N i is the running revolutions of the bearing under this load step;

[0037] The amount of time series...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com