A welding tool for antenna vibrator processing

A welding tool and antenna vibrator technology, applied in welding equipment, metal processing equipment, auxiliary welding equipment, etc., can solve the problems of welding position deviation, poor signal, unstable fixing method, etc., to avoid shaking, avoiding spark burns, Precise welding position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

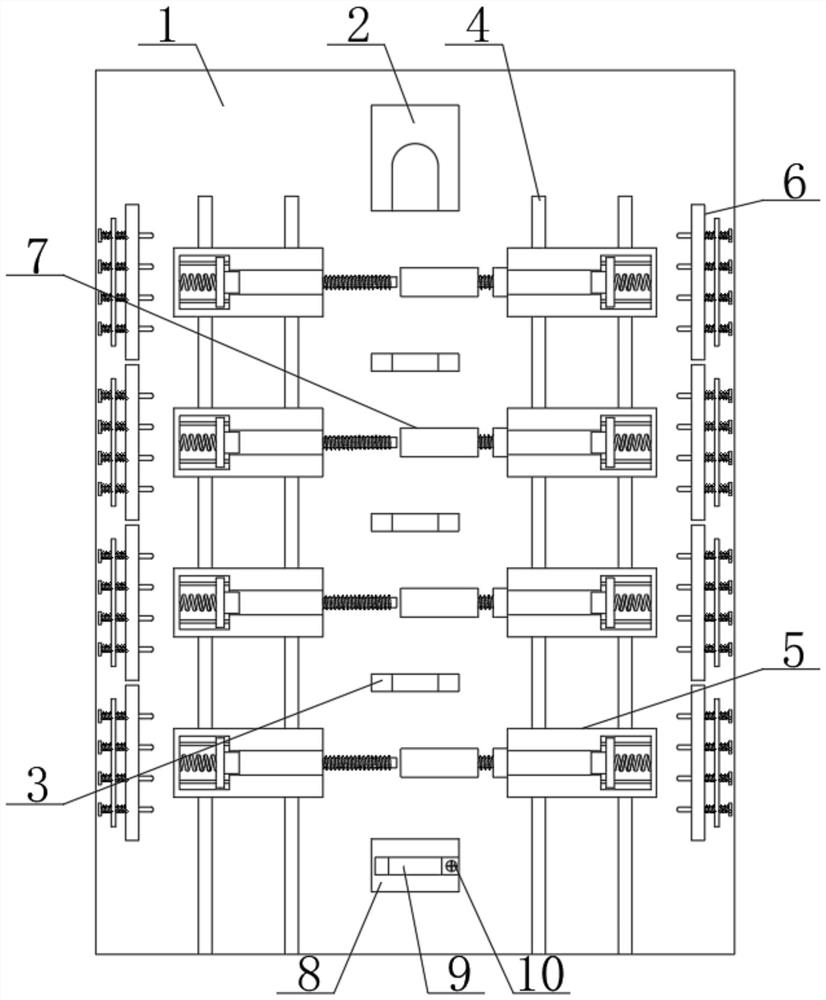

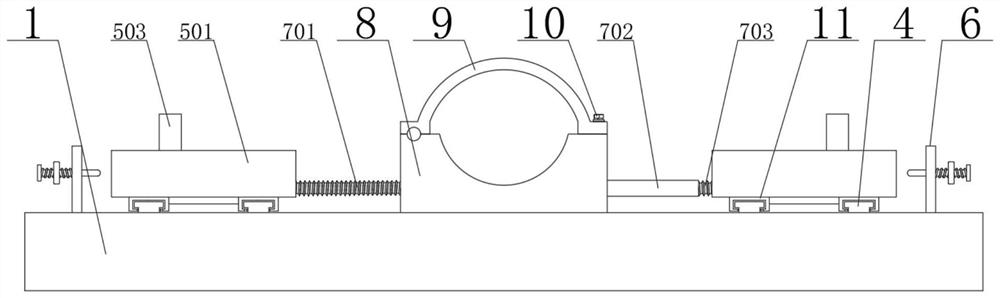

[0025] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the present invention provides a kind of technical scheme:

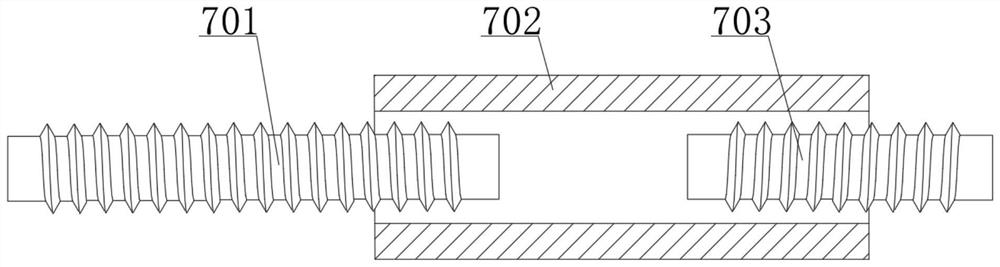

[0026] A welding tool for antenna vibrator processing, comprising a base plate 1 and an upper unit fixing block 2, an upper unit fixing block 2 is fixedly connected above the center of the front end surface of the base plate 1, and a connection device 7 arranged alternately up and down is arranged below the upper unit fixing block 2 and the limit frame 3, a lower unit fixing block 8 is fixedly connected below the center of the front end surface of the bottom plate 1, a snap ring 9 is rotatably connected to the front end surface of the lower unit fixing block 8, and a screw 10 is provided on the front side of the snap ring 9, and the connecting device 7 includes a left The unit screw rod 701 and the screw sleeve 702, the left end surface of the left unit screw rod 701 is fixedly connected with the limiting device 5, the right side of the left u...

Embodiment 2

[0029]In Embodiment 2, the same parts as those in Embodiment 1 will not be repeated, the difference is that when the welding support rod needs to be welded symmetrically, at this time, the spiral sleeve 702 is rotated to make it move to the left, and then the spiral sleeve 702 is moved to the left. Then, it is screwed with the left unit screw rod 701 to realize the connection of the limiting devices 5 on both sides, so as to ensure that the support rods on the left and right sides can be symmetrical, so as to ensure that they can be welded symmetrically.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com