A component honing system

A technology of parts and honing, which is applied in the direction of honing machine tools, grinding workpiece supports, grinding feed movement, etc., can solve the problems of low efficiency, manual operation level and experience dependence, etc., to improve production efficiency and reduce labor Dependence on operating level and experience, effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

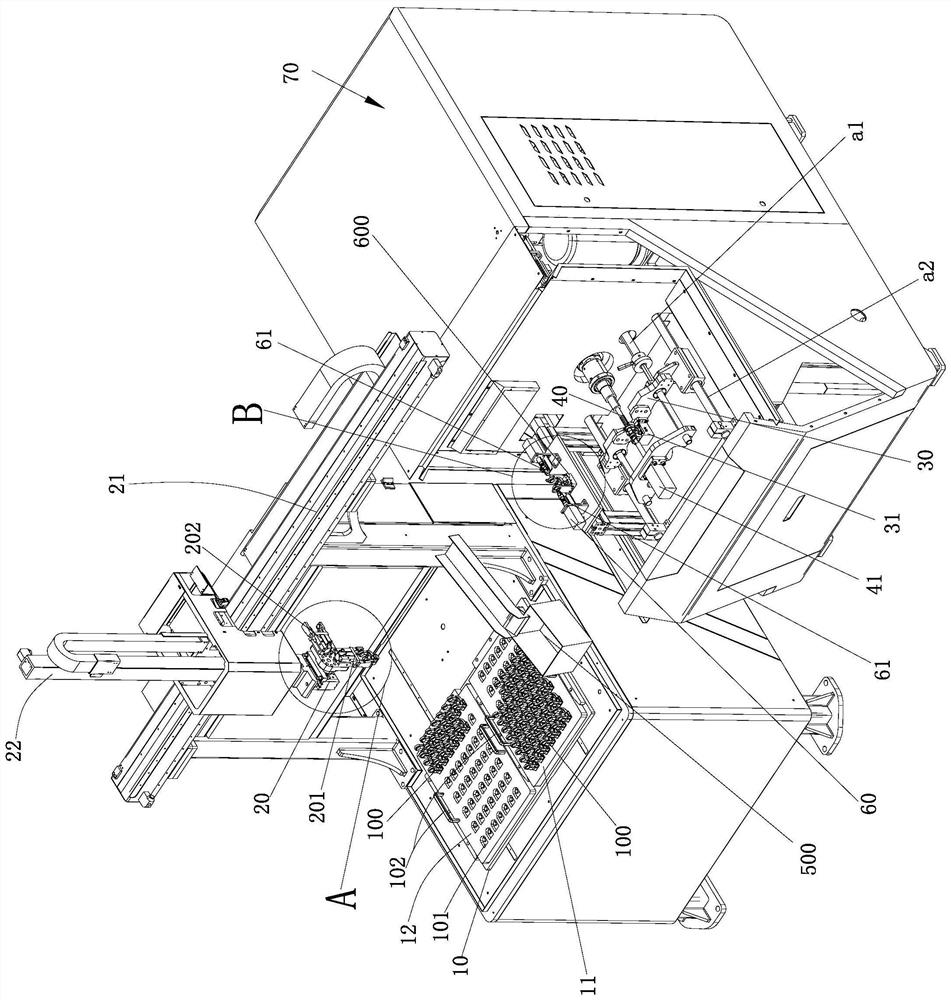

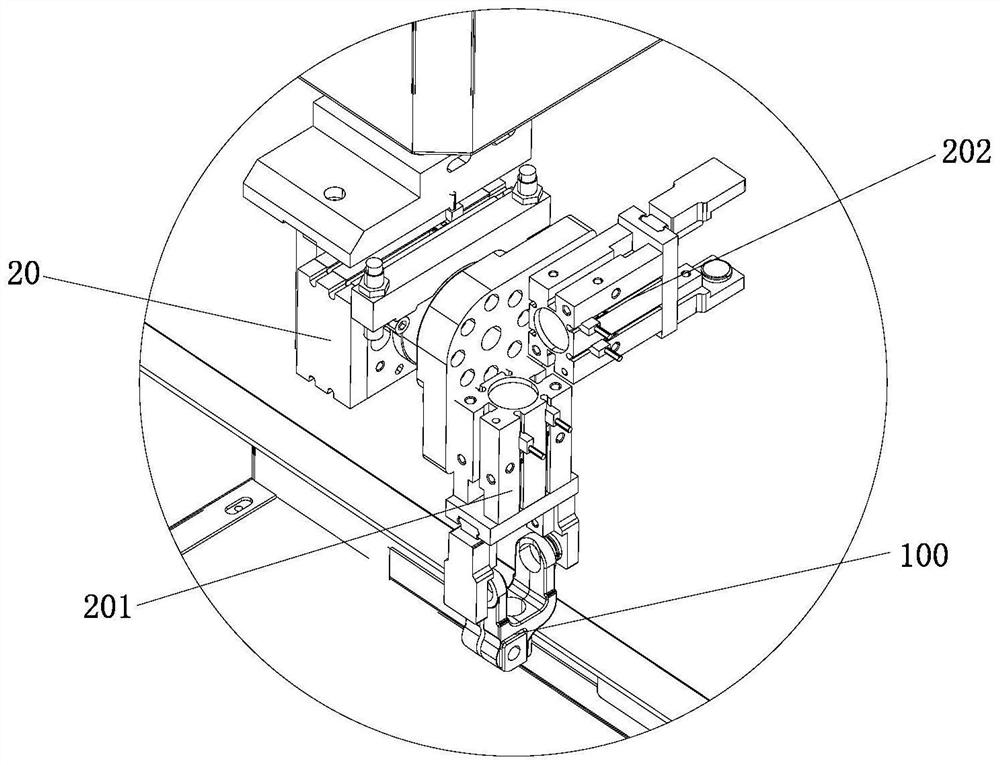

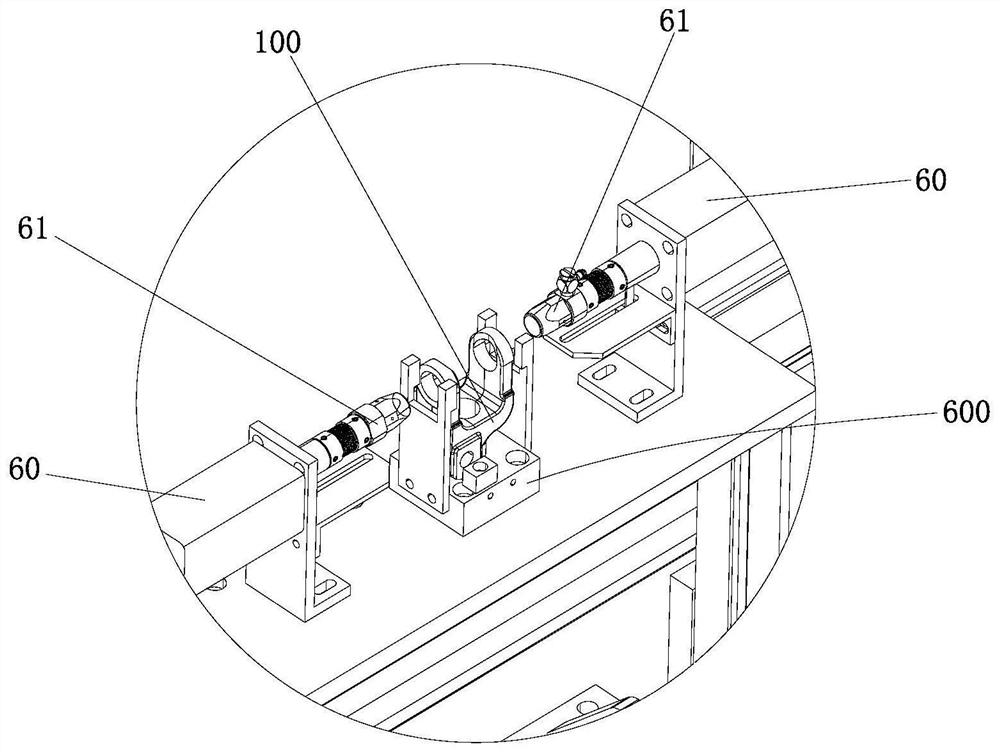

[0024] like Figure 1 to Figure 4 As shown, a component honing system, the honing system has transverse and longitudinal directions parallel to the horizontal plane and perpendicular to each other, the honing system includes an equipment rack, a honing mechanism arranged on the equipment rack for honing parts, and a honing mechanism arranged on the equipment rack. The loading and unloading mechanism on the frame, the honing mechanism includes a CNC honing machine 70, a clamping mechanism for supporting and positioning the parts, and the loading and unloading mechanism has a first placement area for placing the parts to be processed, and a second place for placing the processed parts. Two placement areas (the first placement area and the second placement area are located on the same side of the clamping mechanism in the transverse direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com