Lifeline device for assisting installation of large-span prefabricated roof truss and construction method thereof

A lifeline, large-span technology, applied in the processing of building materials, construction, building construction, etc., can solve problems such as heavy components, workers unable to tie seat belts, safety accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

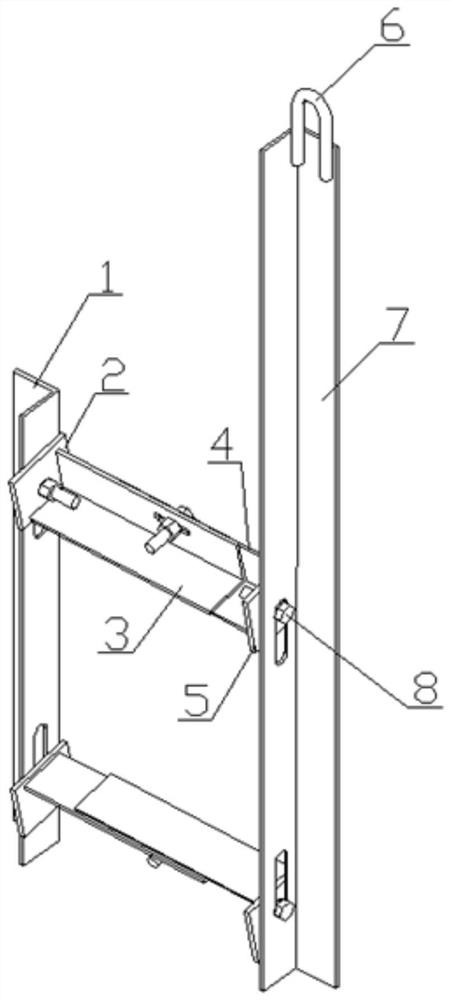

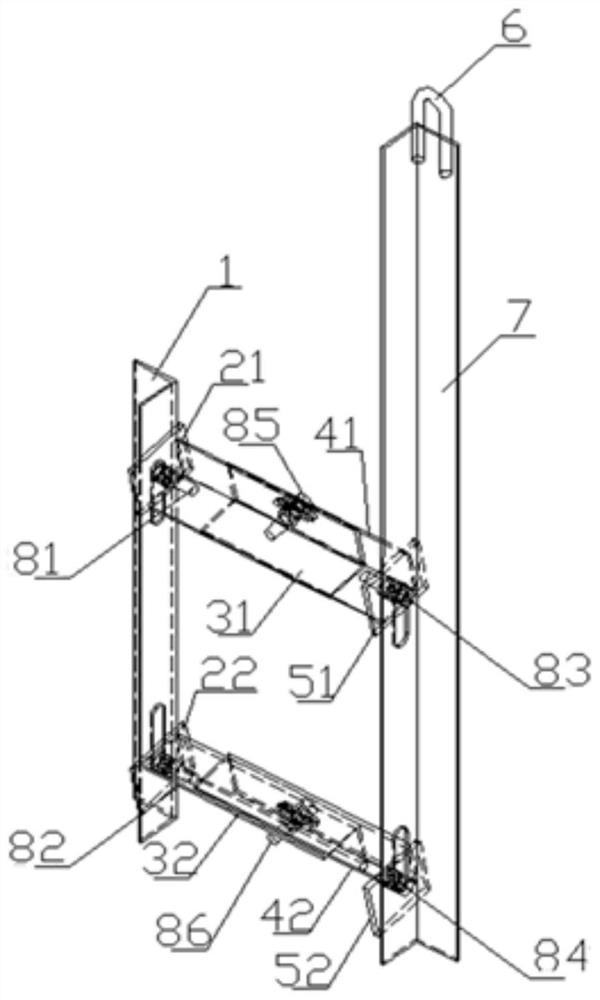

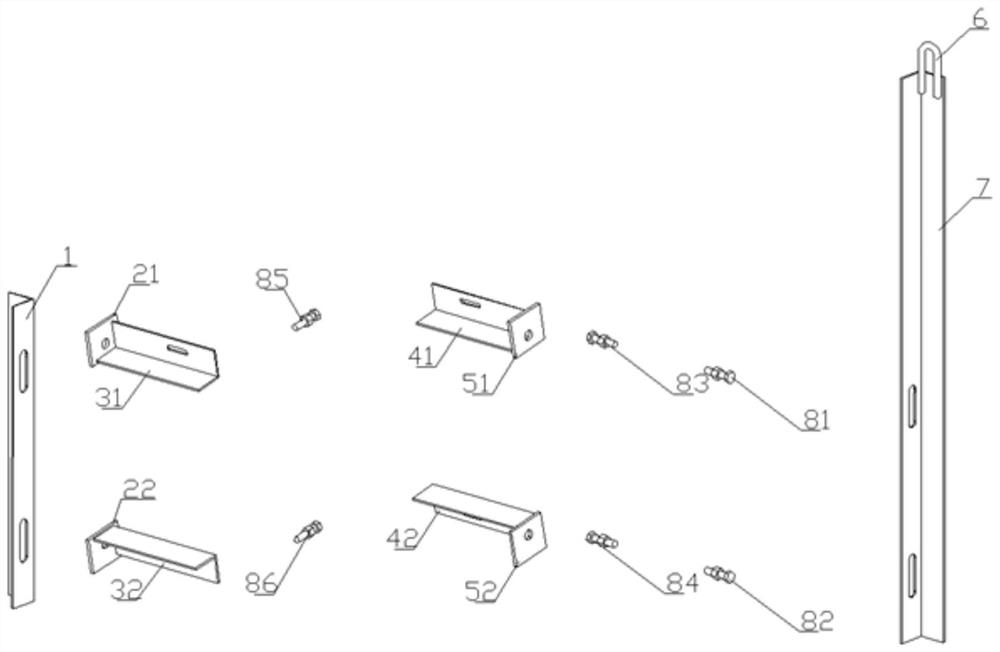

[0047] This embodiment provides a lifeline device for assisting the installation of large-span prefabricated roof trusses, which is used for fixing on prefabricated roof trusses. figure 1 is a schematic diagram of the structure of this embodiment, such as figure 1 As shown, it includes a first column 1, a second column 7, a first connection assembly, and a second connection assembly, wherein:

[0048] The first column 1 is shorter than the second column 7, and the top of the second column 7 is provided with a snap ring 6 for clamping the wire rope 9;

[0049] One end of the first connecting component is connected to the first column 1 through the first connecting piece 81, and the other end of the first connecting component is connected to the second column 7 through the second connecting piece 82;

[0050] One end of the second connection assembly is connected to the first column 1 through the third connection piece 83, and the other end of the second connection assembly is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com