Support device for ultra-low temperature thermally decoupled turbine rotor

A supporting device and thermal decoupling technology, which is applied to components of pumping devices for elastic fluids, non-variable pumps, radial flow pumps, etc., can solve the problem of endangering the operation of compressor units and affecting the safe operation of compressors , Compressor rotor system instability and other issues, to achieve reliable fixation and support, prevent axial movement, and ensure consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below with reference to the accompanying drawings and specific examples.

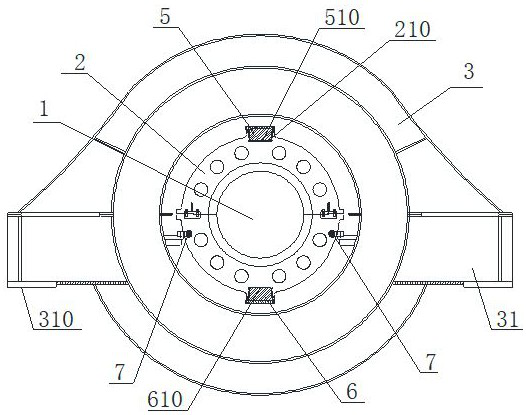

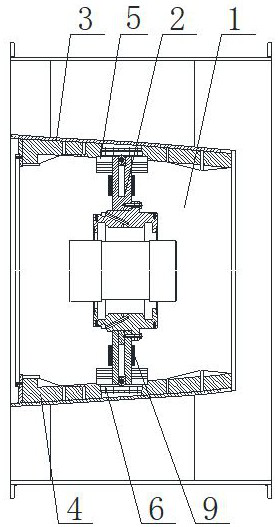

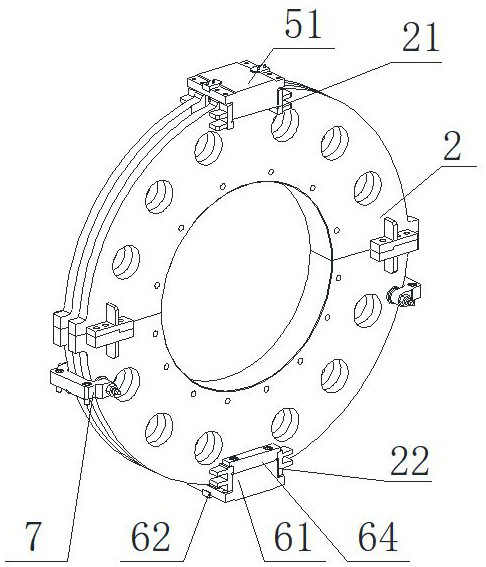

[0034] See figure 1 and 2 A support device for ultra-low thermal decoupling turning rotor, including a bearing box support 2, a top fixing assembly 5, a bottom fixing assembly 6, a clamping assembly 7, and an insulating assembly; an insulation assembly is disposed within the casing 3; See image 3 Attachment Image 6 The top of the bearing box support 2 is provided with a first key groove 21 that matches the top fixing assembly 5, and the bottom portion of the bearing box support 2 is provided with a second key slot 22 that matches the bottom fixing assembly 6, so that the bearing box The support body 2 is fixedly mounted within the casing 3 through the top fixing assembly 5 and the bottom fixing assembly 6, and the bearing box support 2 limits circumferential, horizontal, vertical and axial displacement by the top fixing assembly 5 and the bottom fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com