Underground metal mine trackless transportation system scheduling simulation method and device

A technology of trackless transportation and simulation method, applied in the direction of instruments, data processing applications, resources, etc., can solve the problems of scattered operation points, large transfer volume, difficult to obtain the optimal ratio of the number of trucks and scrapers, etc., to save Time and distance cost, increased efficiency, effect of increasing average utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

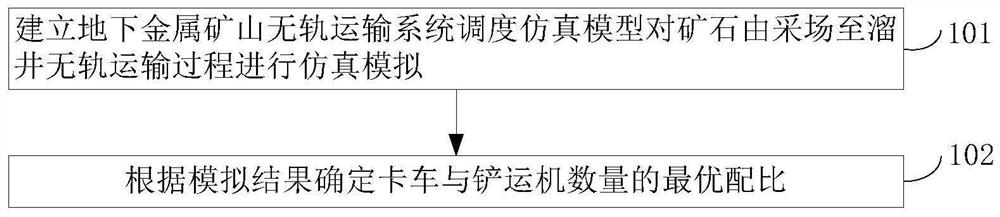

[0044] Such as figure 1 As shown, the embodiment of the present invention provides an underground metal mine trackless transportation system scheduling simulation method, the method can be implemented by electronic equipment, the electronic equipment can be a terminal or a server, the method includes:

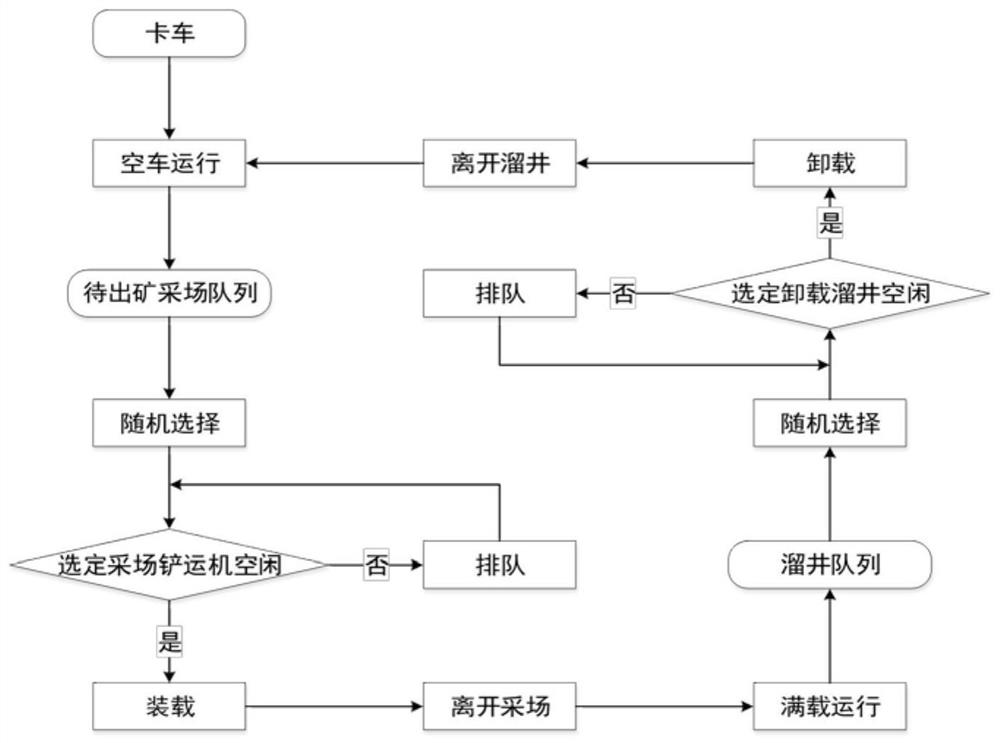

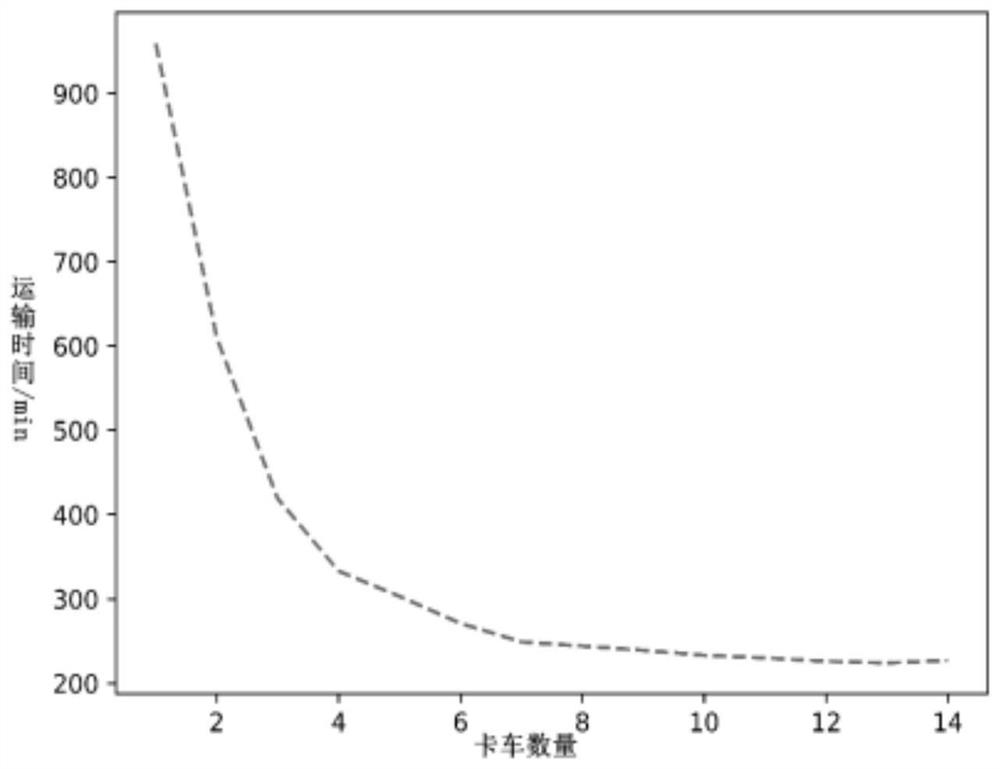

[0045] S101, establishing a scheduling simulation model of the underground metal mine trackless transportation system to simulate the trackless transportation process of the ore from the stope to the chute; wherein, each stope is equipped with a scraper that loads the ore to the truck; the simulation model is used for Simulate the ore trackless transportation process with different numbers of trucks under the cooperation of trucks and L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com