Locomotive running gear fault detection method and device based on time sequence images and storage medium

A technology for fault detection and running parts, which is applied in image analysis, image data processing, graphics and image conversion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] This embodiment provides a time-series image-based fault detection method for running parts of a locomotive, including:

[0064] S01: Obtain a time-series image dataset of the running part of the locomotive;

[0065] During implementation, the position of the high-definition camera is fixed, and the same running part of the locomotive is photographed at a fixed time interval to obtain z normal image data sets {x 1 , x 2 ,...,x z}, where x i Indicates the image collected for the i-th time.

[0066] S02: Perform unified size preprocessing on the acquired time-series image data set of the running part of the locomotive;

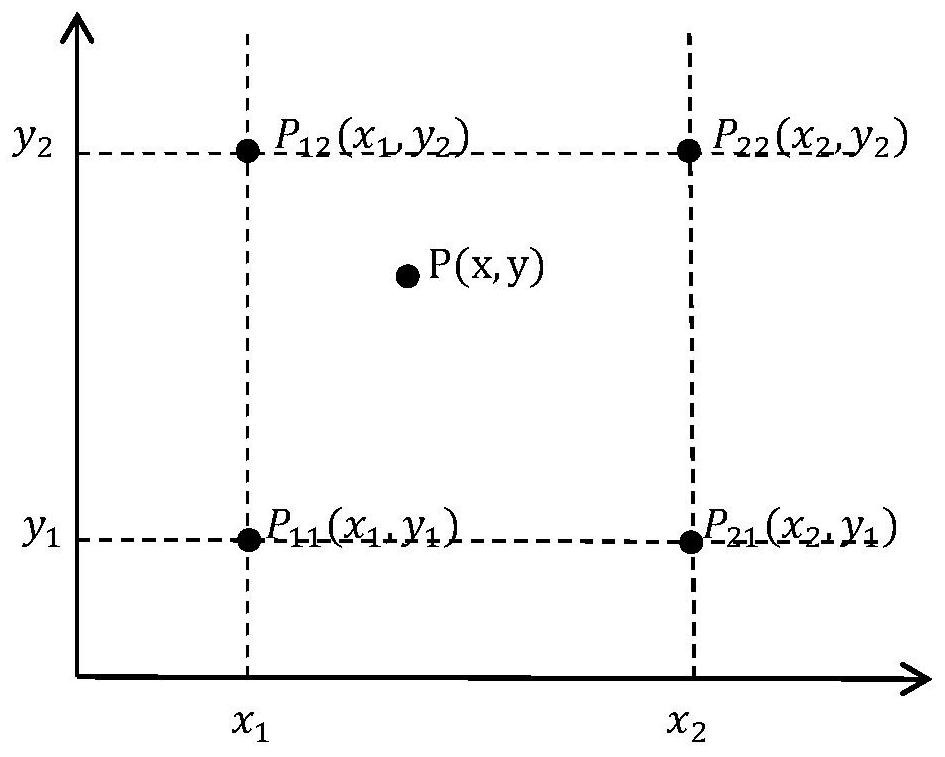

[0067] Since the positions of the locomotives cannot be exactly the same every time they stop, there are problems of geometric changes and inconsistencies in the size of the intercepted key part data set pictures. In order to unify the size of the image, based on the acquired time series image data set of the running part of the locomotive, the inter...

Embodiment 2

[0099] This embodiment provides a time-series image-based fault detection device for running parts of a locomotive, including:

[0100] The image acquisition module is used to acquire the time-series image data set of the running part of the locomotive, and perform unified size preprocessing;

[0101] The time series residual data set acquisition module is used to select a number of normal and fault-free sequence images based on the preprocessed locomotive running part time series image data set, and perform the gray level difference between two time series adjacent images in order to obtain the time series Residual dataset;

[0102] The standard template acquisition module is used to calculate the gray average value of the image in the time series residual data set to obtain the standard template;

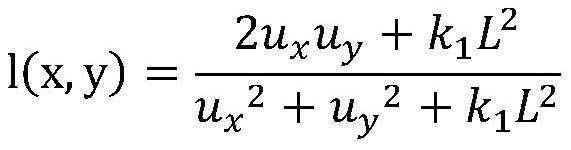

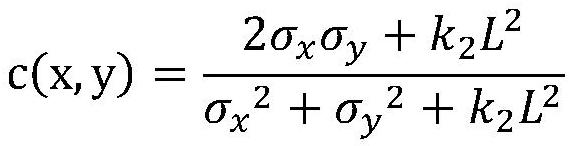

[0103] The similarity acquisition module is used to randomly extract a preset number of images from the time series residual data set, and calculate its structural similarity with ...

Embodiment 3

[0122] In a third aspect, a computer-readable storage medium is provided, which stores a computer program, and the computer program is adapted to be loaded by a processor and execute the time-series image-based fault detection method for running parts of a locomotive as described in Embodiment 1.

[0123] Those skilled in the art should understand that the embodiments of the present application may be provided as methods, systems, or computer program products. Accordingly, the present application may take the form of an entirely hardware embodiment, an entirely software embodiment, or an embodiment combining software and hardware aspects. Furthermore, the present application may take the form of a computer program product embodied on one or more computer-usable storage media (including but not limited to disk storage, CD-ROM, optical storage, etc.) having computer-usable program code embodied therein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com