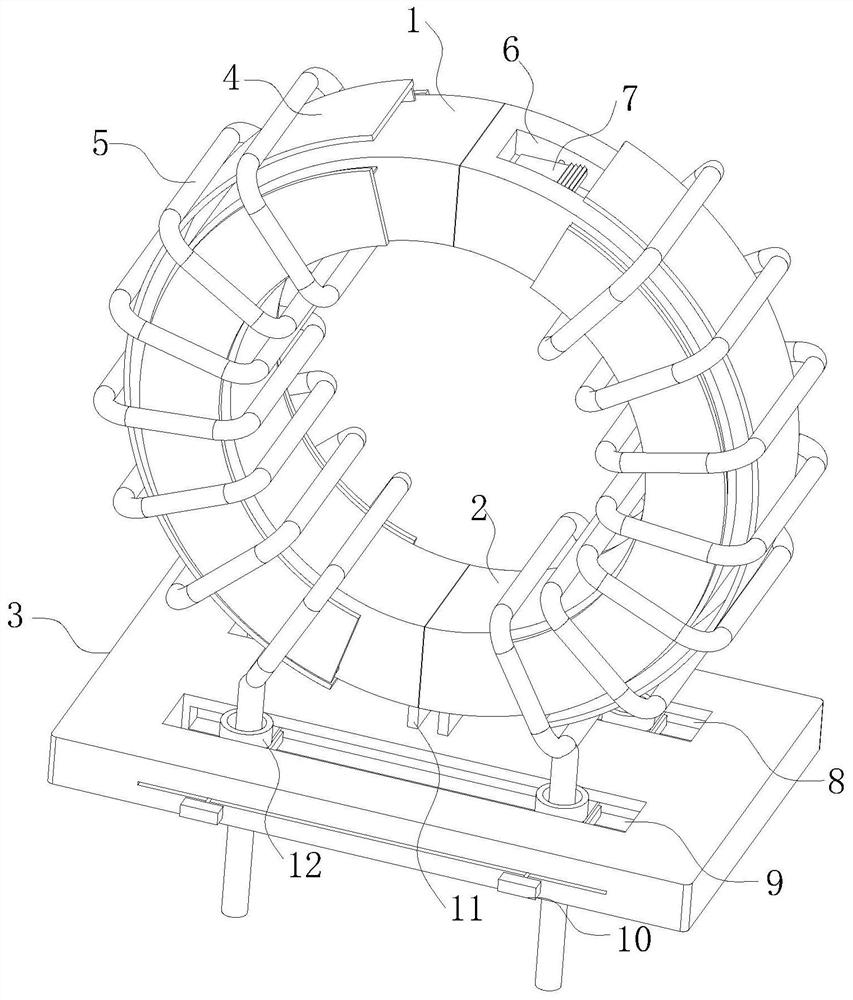

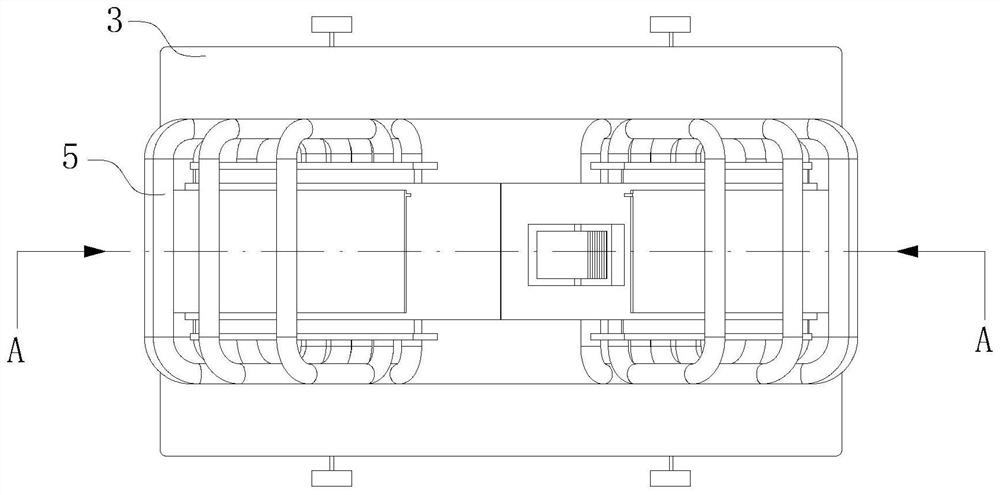

Electromagnetic coil

A technology of electromagnetic coils and wires, applied in transformer/inductor coils/windings/connections, circuits, electrical components, etc. The effect of sustainable development and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

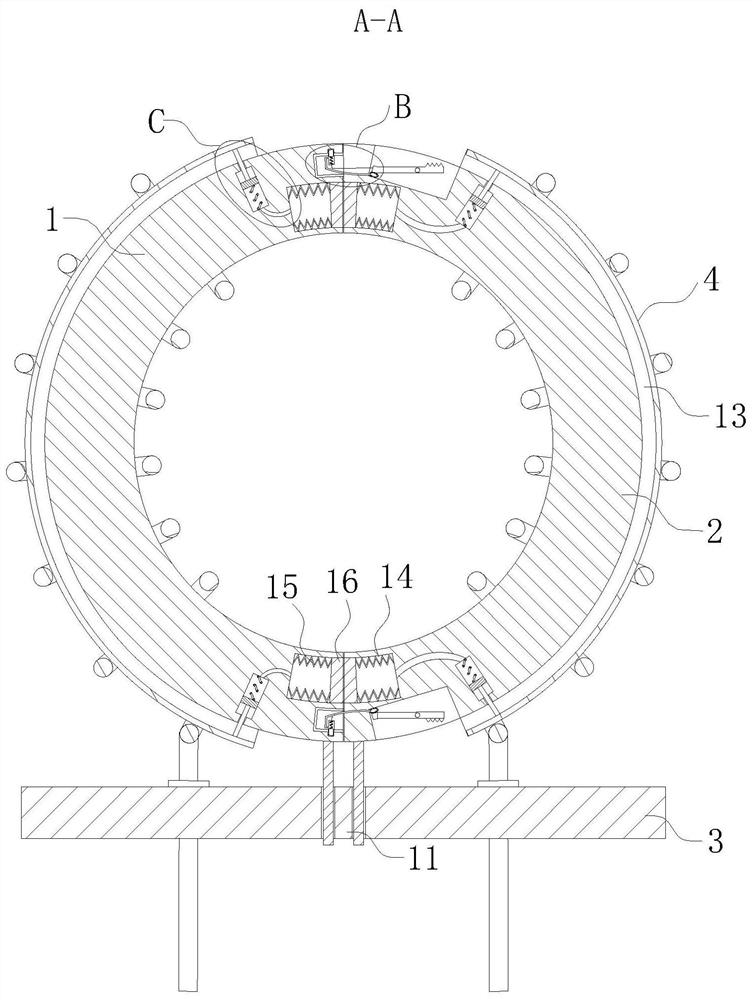

[0036] As an embodiment of the present invention, the gas control device includes a storage groove 14, a first spring compression tube 15, a push rod 25, a cylindrical cavity 26 and a piston plate 27; the storage groove 14 is located at the left arc winding The end of the rod 1 and the end of the right arc-shaped winding rod 2; the bottom of the receiving groove 14 is fixedly connected with one end of the first spring compression tube 15; the other end of the first spring compression tube 15 is connected with the compression The surface of the block 16 is fixed; the bottom of the first spring compression tube 15 communicates with the cylindrical cavity 26 located inside the left arc winding rod 1 and the right arc winding rod 2; the cylindrical cavity 26 is close to One end of the receiving groove 14 is fixedly connected with one side of the piston plate 27 through a spring; the other side of the piston plate 27 is fixedly connected with one end of the push rod 25; and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com